Graphite nanosheet conductive ink as well as preparation method and application thereof

A technology of graphite nanosheets and conductive inks, applied in the directions of ink, graphite, application, etc., can solve the problems of low viscosity and concentration of conductive inks, reduced lateral size or length, and reduced lateral size or length, etc. Concentration, conductivity and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Preparation of graphite nanosheet conductive ink

[0091] (1) According to the material content in Table 3, dissolve the linking agent in the solvent in the barrel of a high-speed mixer at a speed of 400 rpm, then add the auxiliary agent and continue stirring until uniform;

[0092] (2) Place the product obtained in step (1) in a colloid mill at a speed of 10000rpm, then simultaneously and slowly add the graphite nanosheets and the conductive carbon black into the colloidal abrasive hopper, and grind for 4h to obtain the obtained Graphite nanosheet conductive ink.

[0093] Graphite nanosheets in Table 3 are the same as Comparative Example 1; polyurethane resins in Table 3 are the same as Comparative Example 1.

[0094] table 3

[0095]

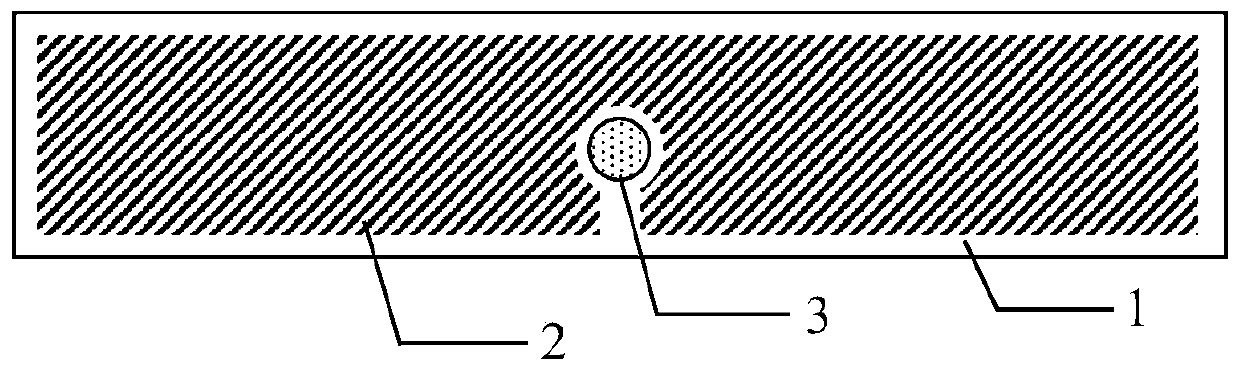

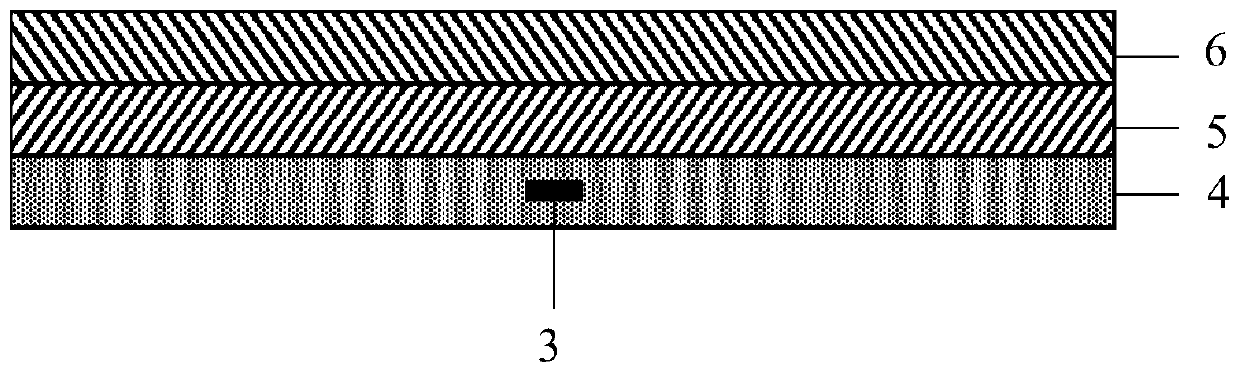

[0096] Preparation of RFID linen label

[0097] (1) Print the graphite nanosheet conductive ink prepared above onto a polyethylene terephthalate (PET) substrate 1 by a screen printing process;

[0098] (2) Place the product obtai...

Embodiment 2

[0103] Preparation of graphite nanosheet conductive ink

[0104] (1) According to the material content in Table 4, dissolve the linking agent in the solvent in the barrel of a high-speed mixer at a speed of 400 rpm, then add the auxiliary agent and continue stirring until uniform;

[0105] (2) Place the product obtained in step (1) in a colloid mill at a speed of 12000rpm, then simultaneously and slowly add the graphite nanosheets and the conductive carbon black into the colloidal abrasive hopper, and grind for 6h to obtain the obtained Graphite nanosheet conductive ink.

[0106] Graphite nanosheets in Table 4 are prepared by jet cavitation method, using jet cavitation equipment disclosed in Chinese patent CN201110190763.3: graphite powder and mixed solvent (prepared by ethanol and water, wherein the volume fraction of ethanol is 50%) are prepared into a graphite dispersion with a concentration of 10 mg / ml. The graphite dispersion was treated with jet cavitation equipment at...

Embodiment 3

[0117] Preparation of graphite nanosheet conductive ink

[0118] (1) According to the material content in Table 5, dissolve the linking agent in the solvent in the high-speed mixer barrel at a speed of 400 rpm, then add the auxiliary agent and continue stirring until uniform;

[0119] (2) Place the product obtained in step (1) in a colloid mill at a speed of 8000rpm, then simultaneously and slowly add the graphite nanosheets and the conductive carbon black into the colloidal abrasive hopper, and grind for 4h to obtain the obtained Graphite nanosheet conductive ink.

[0120] Graphite nanosheets in Table 5 were prepared by a high-speed shearing method: graphite powder and a mixed solvent (prepared from ethanol and water, wherein the volume fraction of ethanol was 50%) were prepared into a graphite dispersion with a concentration of 15 mg / ml. Put the graphite dispersion in a high-speed machine, process it at 8000 rpm for 6 hours, and then filter and dry the obtained dispersion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com