Method for preparing ultra-coarse grain cemented carbide by flexible ball milling technology

A cemented carbide and ball milling technology, applied in the field of ultra-coarse-grained cemented carbide prepared by flexible ball milling technology, can solve the problems of long process, complicated process, and high production cost, and achieve the effect of short process, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

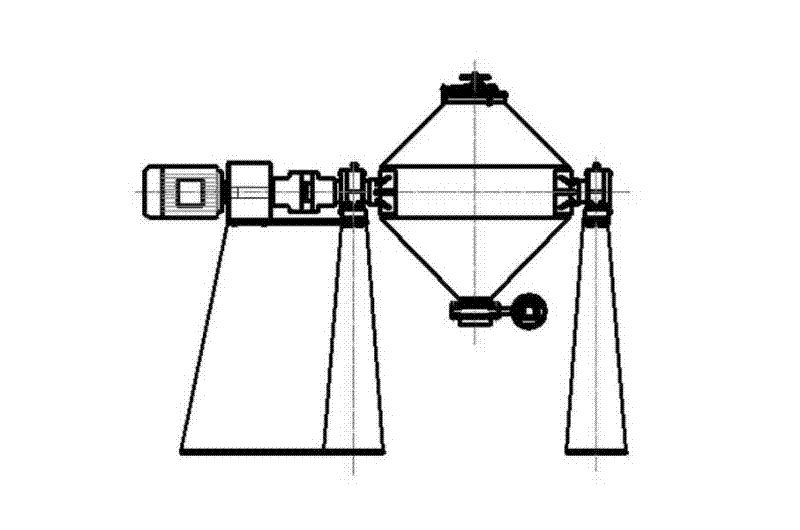

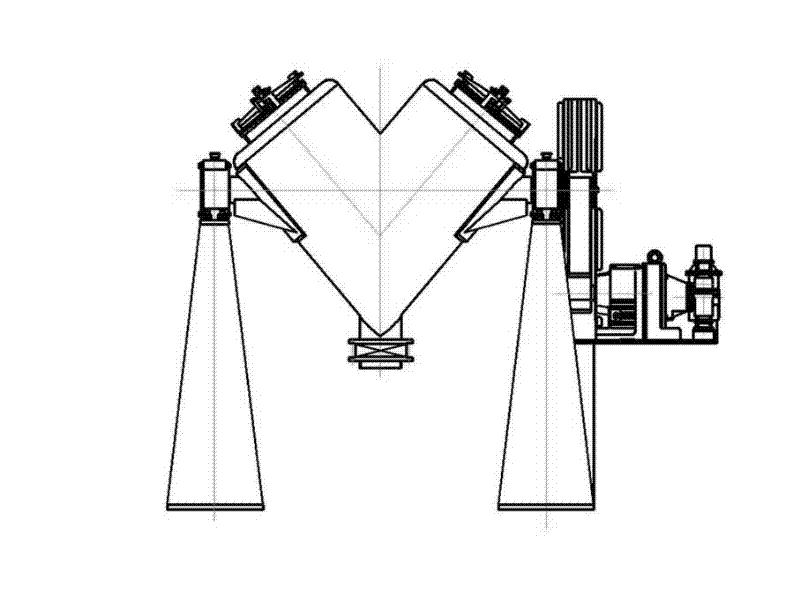

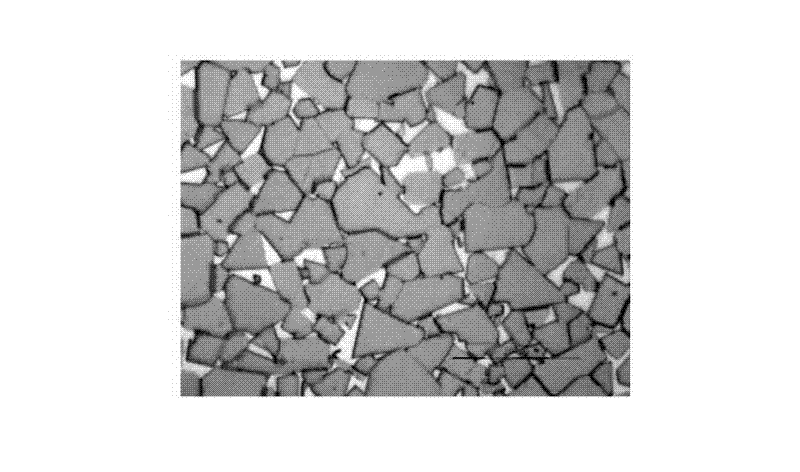

[0023] Ultra-coarse-grained cemented carbide composition WC-6Co, WC raw material Fisher grain size 20.1μm. First pre-mix the WC powder and Co powder in a double-cone or Y-shaped mixer, the pre-mixing time is 0.5h, and the mixer speed is 12rpm; then put the pre-mixed powder into the ball mill for a short period of light ball milling. Add alcohol and paraffin, the material of the grinding ball is WC-Co cemented carbide, its diameter is φ6~φ10mm, the ball milling time is 10h, the ratio of ball to material is 2.5:1, and the speed of the ball mill is 35% of the critical speed; then discharge the slurry in the ball mill , using spray drying to prepare the mixture, followed by pressing and sintering at a temperature of 1480 ° C to obtain an ultra-coarse grained cemented carbide.

[0024] Results: The average grain size of the coarse-grained cemented carbide is 7.0 μm, the hardness is HV30 1140, the porosity is A00B00, image 3 Photographs for metallography.

Embodiment 2

[0026] Ultra-coarse-grained cemented carbide composition WC-10Co, WC raw material Fisher grain size 20.2μm. First pre-mix WC powder and Co powder in a double-cone or Y-shaped mixer, the pre-mixing time is 1.5h, and the mixer speed is 8rpm; then put the pre-mixed powder into a ball mill for a short period of light ball milling. Add alcohol and paraffin, the material of the grinding ball is WC-Co cemented carbide, its diameter is φ6~φ10mm, the ball milling time is 18h, the ratio of ball to material is 2.2:1, and the speed of the ball mill is 50% of the critical speed; then discharge the slurry in the ball mill , using spray drying to prepare the mixture, followed by compression molding, and sintering at a temperature of 1450 ° C to obtain an ultra-coarse-grained cemented carbide.

[0027] Results: The average grain size of ultra-coarse-grained cemented carbide is 9.0 μm, the hardness is HV30 1000, the porosity is A02B00, Figure 4 Photographs for metallography.

Embodiment 3

[0029] Ultra-coarse-grained cemented carbide composition WC-17.5Co, WC raw material Fisher grain size 21.4μm. First pre-mix WC powder and Co powder in a double-cone or Y-shaped mixer. The pre-mixing time is 2 hours, and the mixer speed is 6 rpm; Add alcohol and PEG, the material of the grinding ball is WC-Co cemented carbide, its diameter is φ6~φ10mm, the ball milling time is 14h, the ball-to-material ratio is 2.5:1, and the speed of the ball mill is 20% of the critical speed; then discharge the slurry in the ball mill, The mixture is prepared by spray drying, followed by pressing and sintering at a temperature of 1390°C to obtain an ultra-coarse-grained cemented carbide.

[0030] Results: The average grain size of ultra-coarse-grained cemented carbide is 10.0 μm, the hardness is HV30 770, the porosity is A00B00, Figure 5 Photographs for metallography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com