Hammer crusher with screening structure

A hammer crusher and screening technology, which is applied in the field of coal mine machinery and equipment, can solve the problems of indistinguishable crushing, etc., achieve the effects of convenient matching, reducing hammer head wear, and avoiding excessive crushing and secondary crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

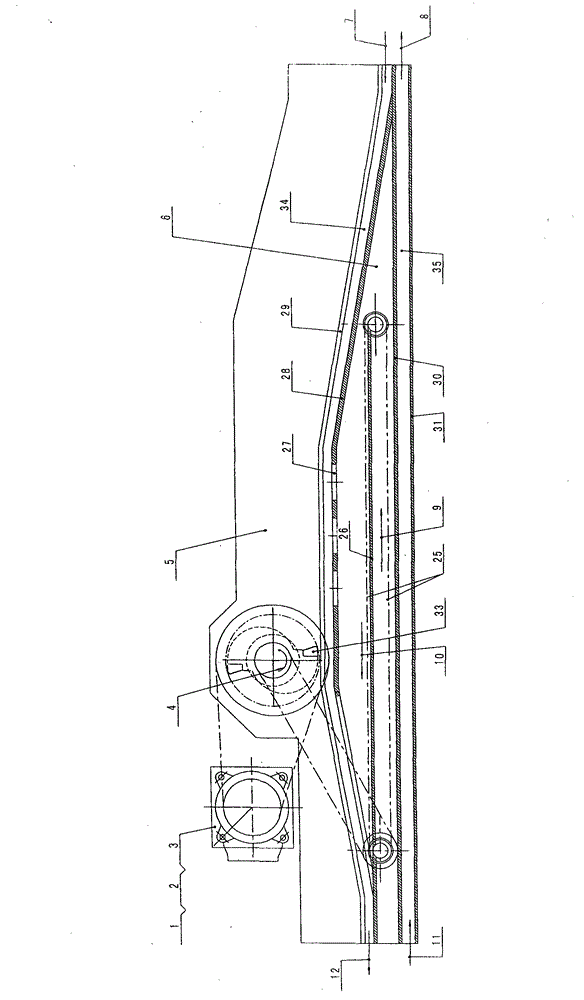

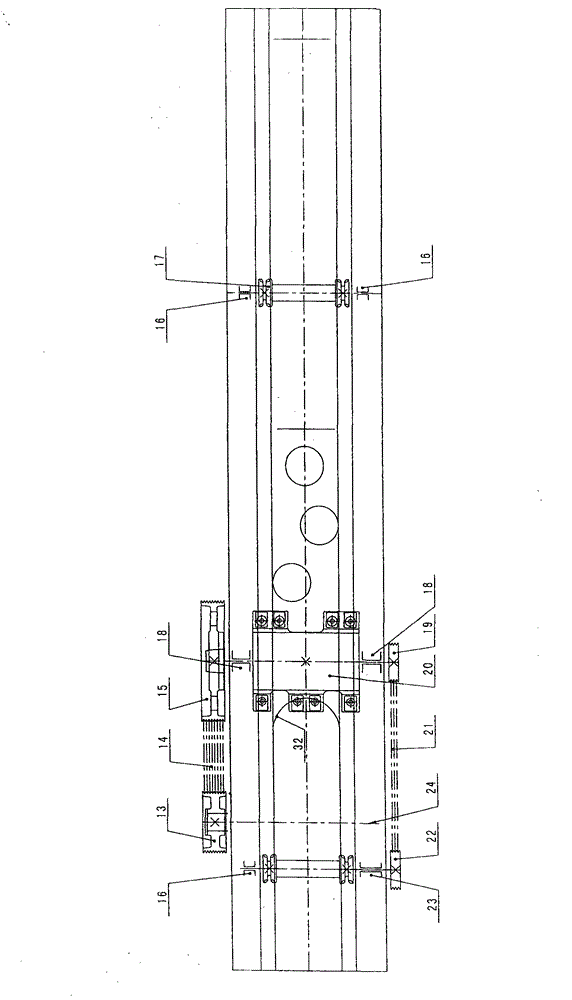

[0013] The hammer crusher with screening structure is mainly composed of a crushing frame body, a bottom tank body, a driving device, a hammer shaft assembly, and an under-screen conveying mechanism. The driving device is composed of motor 1, elastic coupling 2, 3, short shaft assembly 3, and small pulley 13; the hammer shaft assembly is composed of hammer body 20, hammer head 33, bearing 18, large pulley 15, and toothed pulley 19 The conveying mechanism under the screen is composed of sprocket 17, bearing 16, scraper chain 25, bearing 23 and toothed pulley 22.

[0014] Such as Figure 1~2 As shown, an upper wing plate 29, an upper middle plate 28, a lower middle plate 30, a bottom plate 31 and an under-screen conveying middle plate 26 are arranged on the crusher bottom tank body 6; the upper middle plate 28 is convex, and the lower middle plate 30 It is flat, and the upper and lower middle plates overlap at both ends to form a space with a high middle and low ends. In this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com