Self-excitation type pulse polycrystalline diamond compact (PDC) drill bit

A self-excited drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of short service life, excessive crushing, and low water efficiency of the drill bit, and achieve the purpose of increasing hydraulic rock breaking capacity and avoiding excessive crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

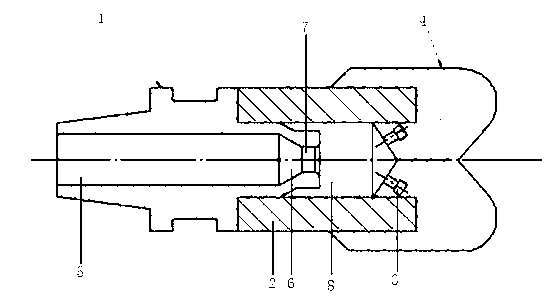

[0011] Embodiment one: in figure 1 Among them, this self-excited pulse PDC drill bit includes the upper drill bit upper body 1, the drill bit upper body 1 is connected to the drill bit body 2 through threads, the inner nozzle 7 is installed inside the drill bit body 2, and the drill bit blade is fixed outside the drill bit body 2 4. The drill bit blade 4 is inlaid with a diamond composite sheet. There is a central hole 5 on the axis of the upper body 1 of the drill bit. The diameter of the central hole 5 is 70 mm; The inner nozzle 7, the lower end of the inner nozzle 7 is the self-excited pulse cavity 8 in the drill body, the lower part of the self-excited pulse cavity 8 is cylindrical, the upper part of the self-excited pulse cavity 8 is a basin-shaped inner slope, and the self-excited pulse cavity 8 The lower part communicates with 4 nozzles 3 .

[0012] The diameter of the inner nozzle 7 is 0.5 times the diameter of the central hole 5, the diameter of the self-excited puls...

Embodiment 2

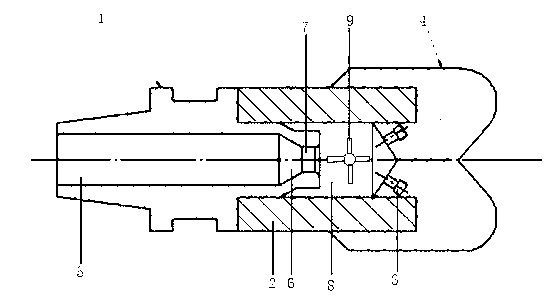

[0013] Embodiment two: in figure 2 Among them, a runner 9 is also installed in the self-excited pulse cavity at the lower part of the inner nozzle inside the drill body. There are 4 blades on the runner. The axis of the horizontal runner and the axis of the vertical center hole do not intersect. The distance is 1 / 10 of the diameter of the center hole. Due to the high-speed rotation of the runner 9, the pressure of the water flow in the self-excited pulse chamber 8 changes at high frequency, so that the impact effect of the water flow is greatly improved.

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com