Low specific density filling master batch for polypropylene injection molding and preparation method of low specific density filling master batch

A filling masterbatch, polypropylene technology, applied in the field of polypropylene injection molding with low specific gravity filling masterbatch and its preparation, can solve the problems of difficult dispersion, broken, easy delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

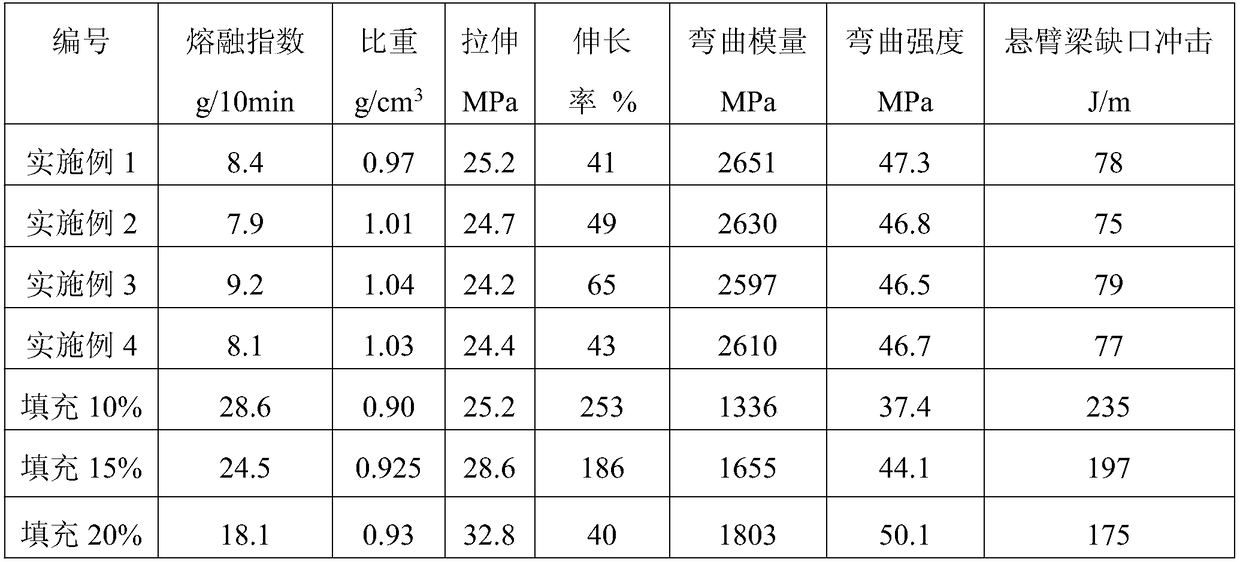

Examples

Embodiment 1

[0014] A low-specific-gravity filler masterbatch for polypropylene injection molding, which includes the following components in parts by weight in every 100g of the polypropylene injection-molding low-specificity filler masterbatch: 35g of polypropylene, 40g of hollow glass microspheres, 18g of talcum powder, and Compatible agent 5g, antioxidant 0.5g and carbon black 1.5g.

[0015] The preparation method of the above filler masterbatch is: put polypropylene, compatibilizer, antioxidant and carbon black in a high-speed mixer, stir and mix at a speed of 450r / min for 3min, and then add it to the co-rotating parallel twin-screw extruder. In the main feeding barrel, put talcum powder and hollow glass microspheres into a high-speed mixer, stir and mix at a speed of 450r / min for 5 minutes, then add them to the side feeding barrel of the co-rotating parallel twin-screw extruder, and finally melt Extrusion, cooling, air drying, pelletizing, sieving, packaging.

Embodiment 2

[0017] A low-specific-gravity filler masterbatch for polypropylene injection molding, which includes the following components in parts by weight in every 100g of the polypropylene injection-molding low-specificity filler masterbatch: 40g of polypropylene, 34g of hollow glass microspheres, 20g of talcum powder, and Compatible agent 3g, antioxidant 1g and carbon black 2g.

[0018] The preparation method of the above filler masterbatch is: put polypropylene, compatibilizer, antioxidant and carbon black in a high-speed mixer, stir and mix at a speed of 400r / min for 5min, and then add it to the co-rotating parallel twin-screw extruder. In the main feeding barrel, put talcum powder and hollow glass microspheres into a high-speed mixer, stir and mix at a speed of 400r / min for 8 minutes, then add them to the side feeding barrel of the co-rotating parallel twin-screw extruder, and finally melt Extrusion, cooling, air drying, pelletizing, sieving, packaging.

Embodiment 3

[0020] A low-specific-gravity filler masterbatch for polypropylene injection molding, which includes the following components in parts by weight in every 100g of the polypropylene injection-molding low-specificity filler masterbatch: 50g of polypropylene, 20g of hollow glass microspheres, 25g of talcum powder, and Compatible agent 3.2g, antioxidant 0.8g and carbon black 1g.

[0021] The preparation method of the above-mentioned filling masterbatch is: put polypropylene, compatibilizer, antioxidant and carbon black in the high-speed mixer, stir and mix with the speed of 350r / min for 8min, then add to the same direction parallel twin-screw extruder In the main feeding barrel, put talcum powder and hollow glass microspheres into a high-speed mixer, stir and mix at a speed of 350r / min for 10 minutes, then add them to the side feeding barrel of a parallel twin-screw extruder, and finally melt Extrusion, cooling, air drying, pelletizing, sieving, packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com