Preparation process of corundum powder

A preparation process and technology of corundum powder, which is applied in the field of corundum powder, can solve the problems of small daily processing capacity, low production efficiency, and poor material uniformity, and achieve the effects of uniform corundum powder particles, high production efficiency, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

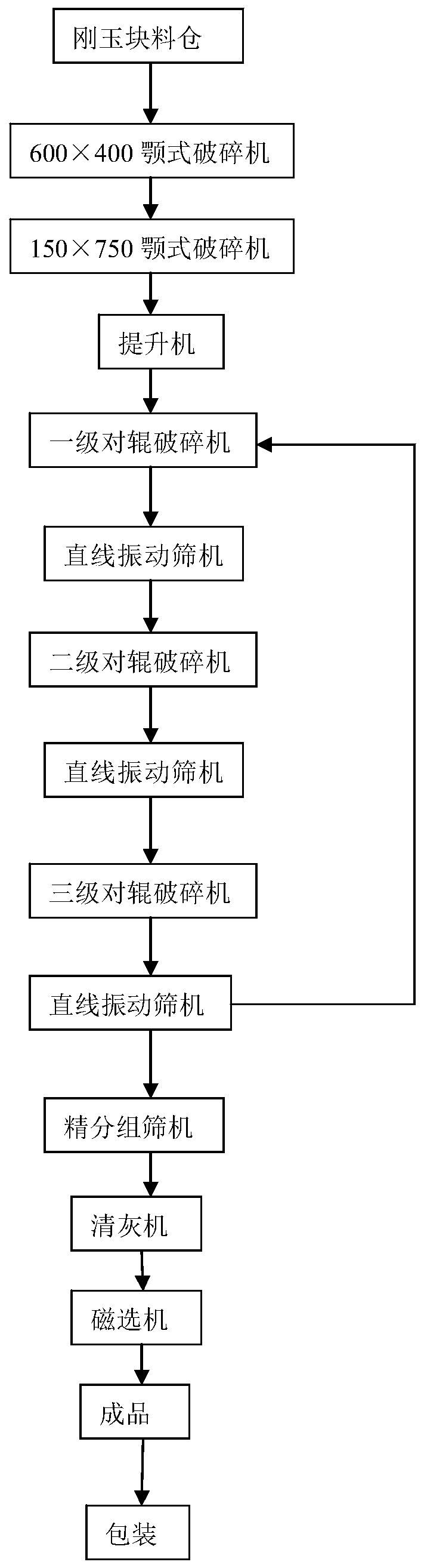

[0030] A preparation process of corundum powder, comprising the following steps:

[0031] (1) coarse crushing

[0032] The white corundum block with a particle size of <250mm is first crushed by a 600×400 jaw crusher, and then crushed by a 150×750 jaw crusher to obtain fine particles with a particle size of <20mm and particles with a particle size of 20mm≤particle size<50mm , wherein the mass ratio of the total mass of the material to the total mass of the crushed materials with a particle size of 20mm≤particle size<50mm is less than 15%;

[0033] (2) Finely crushed

[0034] The fine and broken materials obtained in step (1) are crushed through the elevator to the first-stage roller crusher, and the materials after the roller crushing are screened through the elevator to the linear vibrating screen machine. After screening, the particle size is less than 0.106 The powder with a particle size of mm is packed into a large bag, and the material with a particle size greater than...

Embodiment 2

[0041] A preparation process of corundum powder, comprising the following steps:

[0042] (1) coarse crushing

[0043] The brown corundum block with a particle size of <250mm is first crushed by a 600×400 jaw crusher, and then crushed by a 150×750 jaw crusher to obtain fine particles with a particle size of <20mm and particles with a particle size of 20mm≤particle size<50mm , wherein the mass ratio of the total mass of the material to the total mass of the crushed materials with a particle size of 20mm≤particle size<50mm is less than 15%;

[0044] (2) Finely crushed

[0045] The fine and broken materials obtained in step (1) are crushed through the elevator to the first-stage roller crusher, and the materials after the roller crushing are screened through the elevator to the linear vibrating screen machine. After screening, the particle size is less than 0.106 The powder with a particle size of mm is packed into a large bag, and the material with a particle size greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com