Iron-based non-crystalline composite coating for protecting heat exchange pipes in flue gas waste heat recovery system of power station boiler and laser re-melting and moulding technology thereof

An iron-based amorphous, flue gas waste heat technology, applied in metal material coating process, coating, fusion spraying, etc., can solve the problem of increasing maintenance workload and material loss, accelerating low-temperature corrosion and ash blocking speed, and burning Deterioration of working conditions and other problems, achieve the effect of alleviating low-temperature acid dew point corrosion, eliminating internal cracks and voids, and excellent wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

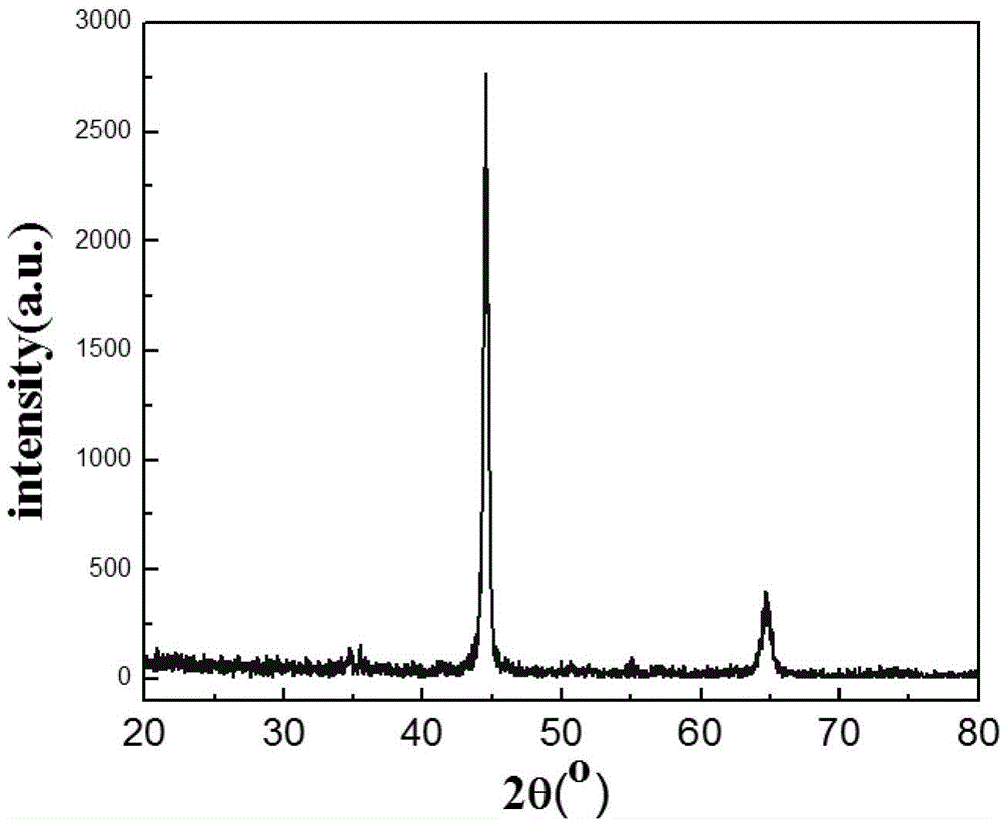

Embodiment 1

[0037] This embodiment discloses an iron-based amorphous composite coating used for protection of heat exchange tubes in a power station boiler flue gas waste heat recovery system. The components in the iron-based amorphous composite coating and their mass percentage wt.% are: Fe: 63.3, Cr: 26.3, B: 2.9, Si: 1.7, Mo: 3.9, Nb: 1.9.

[0038] The laser remelting forming process of the iron-based amorphous composite coating used for the protection of the heat exchange tube in the power station boiler flue gas waste heat recovery system, the process includes the following steps:

[0039] (1) The iron-based amorphous powder-cored wire is prepared by the existing powder-cored wire rolling technology. The components in the iron-based amorphous powder-cored wire and their mass percentage wt.% are: Fe: 63.3, Cr : 26.3, B: 2.9, Si: 1.7, Mo: 3.9, Nb: 1.9, the outer diameter of the iron-based amorphous powder core wire is 1.6mm;

[0040] (2) The surface of the heat exchange tube in the power sta...

Embodiment 2

[0047] This embodiment discloses an iron-based amorphous composite coating used for protection of heat exchange tubes in a power station boiler flue gas waste heat recovery system. The components in the iron-based amorphous composite coating and their mass percentage wt.% are: Fe: 63.9, Cr: 27.0, B: 3.4, Si: 1.8, Mo: 2.0, Nb: 1.9.

[0048] The laser remelting forming process of the iron-based amorphous composite coating used for the protection of the heat exchange tube in the power station boiler flue gas waste heat recovery system, the process includes the following steps:

[0049] (1) The existing powder core wire rolling technology is used to prepare iron-based amorphous powder core wire. The components in the iron-based amorphous powder core wire and their mass percentage wt.% are: Fe: 63.9, Cr : 27.0, B: 3.4, Si: 1.8, Mo: 2.0, Nb: 1.9, the outer diameter of the iron-based amorphous powder core wire is 1.8mm;

[0050] (2) The surface of the heat exchange tube in the power statio...

Embodiment 3

[0053] This embodiment discloses an iron-based amorphous composite coating used for protection of heat exchange tubes in a power station boiler flue gas waste heat recovery system. The components in the iron-based amorphous composite coating and their mass percentage wt.% are: Fe: 65.0, Cr: 26.5, B: 2.9, Si: 1.7, Mo: 2.0, Nb: 1.9.

[0054] The laser remelting forming process of the iron-based amorphous composite coating used for the protection of the heat exchange tube in the power station boiler flue gas waste heat recovery system, the process includes the following steps:

[0055] (1) The existing powder core wire rolling technology is used to prepare iron-based amorphous powder core wire. The components in the iron-based amorphous powder core wire and their mass percentage wt.% are: Fe: Fe: 65.0 , Cr: 26.5, B: 2.9, Si: 1.7, Mo: 2.0, Nb: 1.9, the outer diameter of the iron-based amorphous powder core wire is 2mm;

[0056] (2) The surface of the heat exchange tube in the power stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com