Reinforcing bar joint

a technology of reinforcement bar and joint, applied in the direction of building reinforcement, construction, building components, etc., can solve the problems of increasing bar diameter, insufficient versatility in terms of bar pitch, and difficulty in performing various bar arrangements or ensuring overlapping lengths, etc., to achieve the effect of strengthening the joining for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

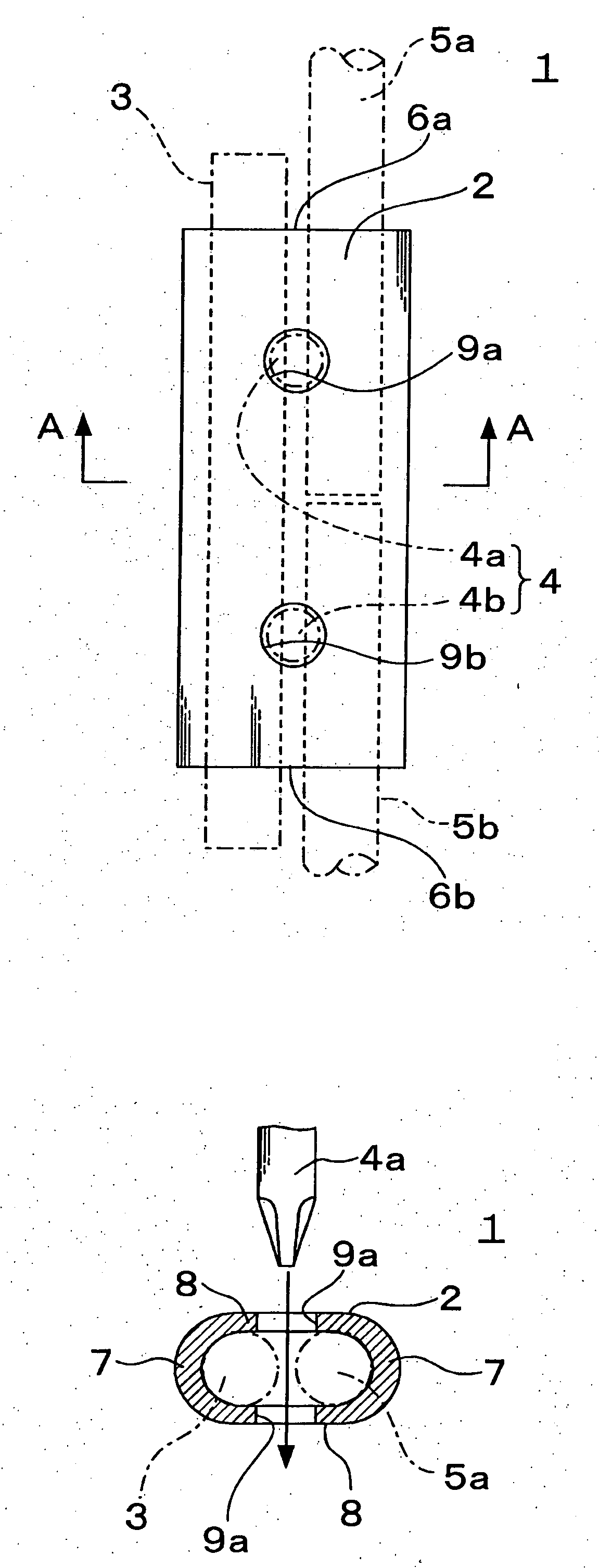

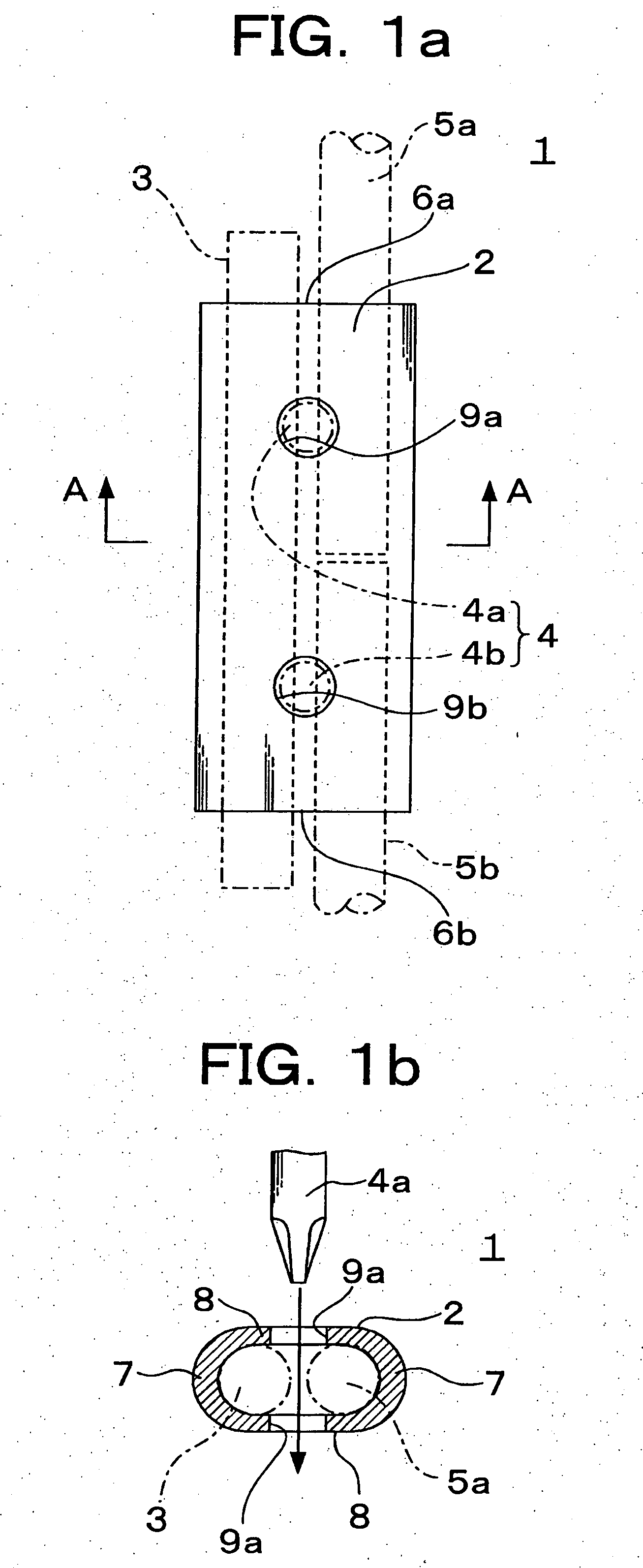

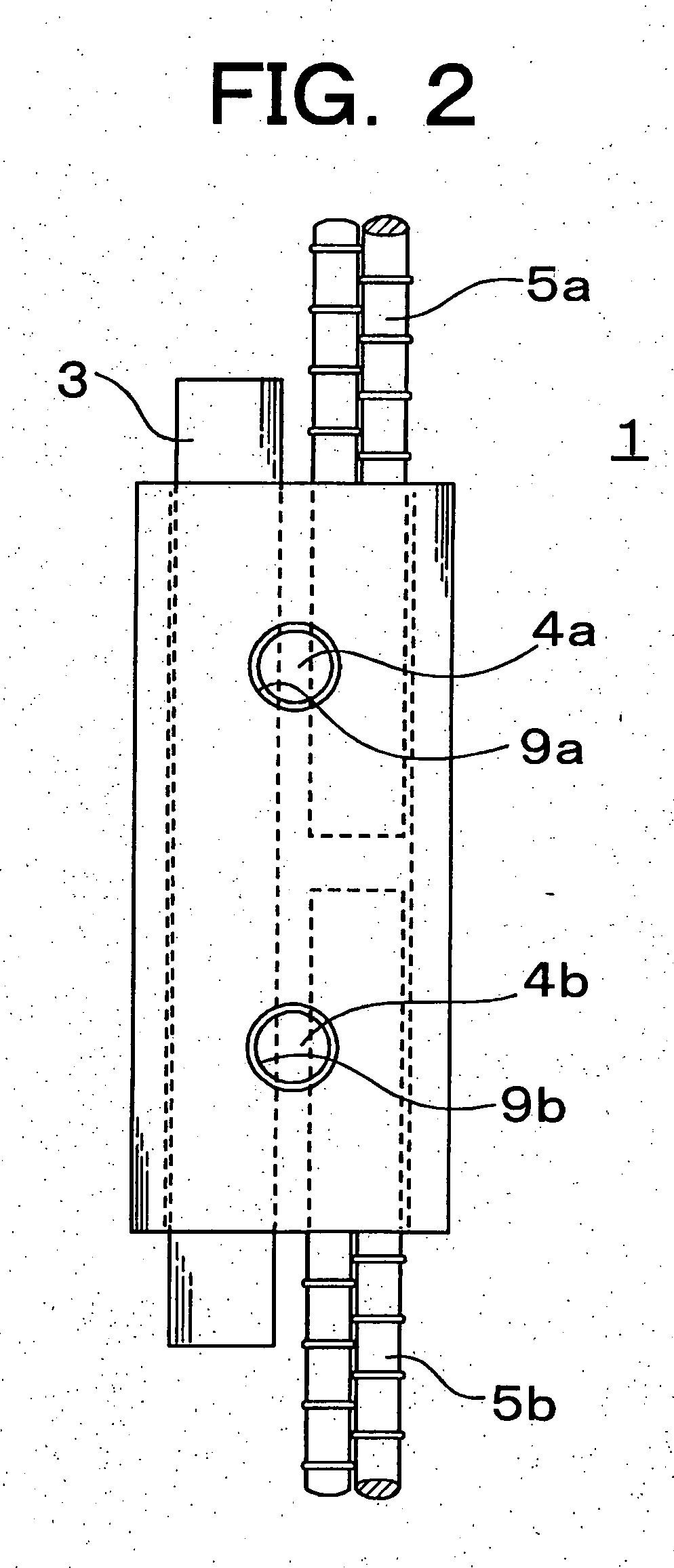

[0054]FIG. 1 is a diagram showing a reinforcing bar joint according to the present embodiment. As shown in the diagram, the reinforcing bar joint 1 according to the present embodiment comprises an elliptic-sectioned sleeve 2, a load transfer rod 3 to be inserted through the sleeve, and wedging means 4.

[0055]The sleeve 2 is configured so that end portions of reinforcing bars 5a, 5b can be inserted into openings 6a, 6b formed in both ends of the sleeve 2 so that the reinforcing bars are arranged in series along an identical line. The load transfer rod 3 can also be inserted therethrough in parallel with the end portions of the reinforcing bars 5a, 5b which are inserted into the sleeve 2.

[0056]The sleeve 2 is composed of a pair of semicylindrical wall portions 7, 7 which are arranged with their curved inner surfaces opposing each other, and a pair of flat wall portions 8, 8 which extend to the corresponding edges of the pair of semicylindrical wall portions. Wedge insertion holes 9a, 9...

embodiment 1

[0074]The following tensile tests were undertaken in order to examine what effects the relative difference in hardness between the reinforcing bars and the load transfer rod has on the tensile characteristics of the reinforcing bar joint according to the present invention.

[0075]The tensile tests undertaken used wedge members having a wedge length of 48 mm, a wedge diameter of 16 mm, and a tip length of 10 mm. Table 1 shows specifications of the sleeves.

TABLE 1thicknesswedgeofinsertionCASESteelLWW1HH1sleeveholeNo.type(mm)(mm)(mm)(mm)(mm)(mm)(mm)1~5STKM 13A140342256.544.56.016.56 7 8 9S45C S45C (annealed) S45C S45C (annealed)220 220 230 23034.4 34.3 34.3 40.0 39.3 40.724.9 24.6 24.6 28.0 28.5 29.862.7 63.1 63.0 69.4 69.9 69.653.3 53.2 53.5 58.1 58.6 58.04.7 4.9 4.8 5.8 5.5 5.616.5

[0076]As can be seen from Table 1, the sleeves tested were of three steel types: STKM13A (carbon steel for machine structural use, JIS), S45C (non-heat treated), and S45C (annealed). The wedge members wer...

second embodiment

[0092]A description will now be given of a second embodiment. It should be appreciated that components and the like substantially identical to those of the foregoing embodiment will be designated by the same reference numerals, and a description thereof will be omitted here.

[0093]FIG. 3 is a diagram showing a reinforcing bar joint according to the second embodiment. As shown in the diagram, the reinforcing bar joint 41 according to the present embodiment comprises an elliptic-sectioned sleeve 2, a load transfer rod 43 to be inserted through the sleeve, and wedging means 4.

[0094]The load transfer rod 43 is composed of a rod body 45 and large diameter portions 44a, 44b which are protruding portions to be attached to respective ends of the rod body. The large diameter portions 44a, 44b are formed to have an outer diameter that is greater than the rod body 45, and internal threads are cut in their internal cavities.

[0095]Conversely, the rod body 45 is made of a straight steel rod having...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com