Micro-etching treatment process and equipment for shiny surface of copper foil

A technology of processing technology and processing equipment, which is applied in the field of copper foil, can solve problems such as blistering, low adhesion, and large coarsened particles of copper foil, and achieve the effects of increasing specific surface area, improving bonding force, and low etching factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

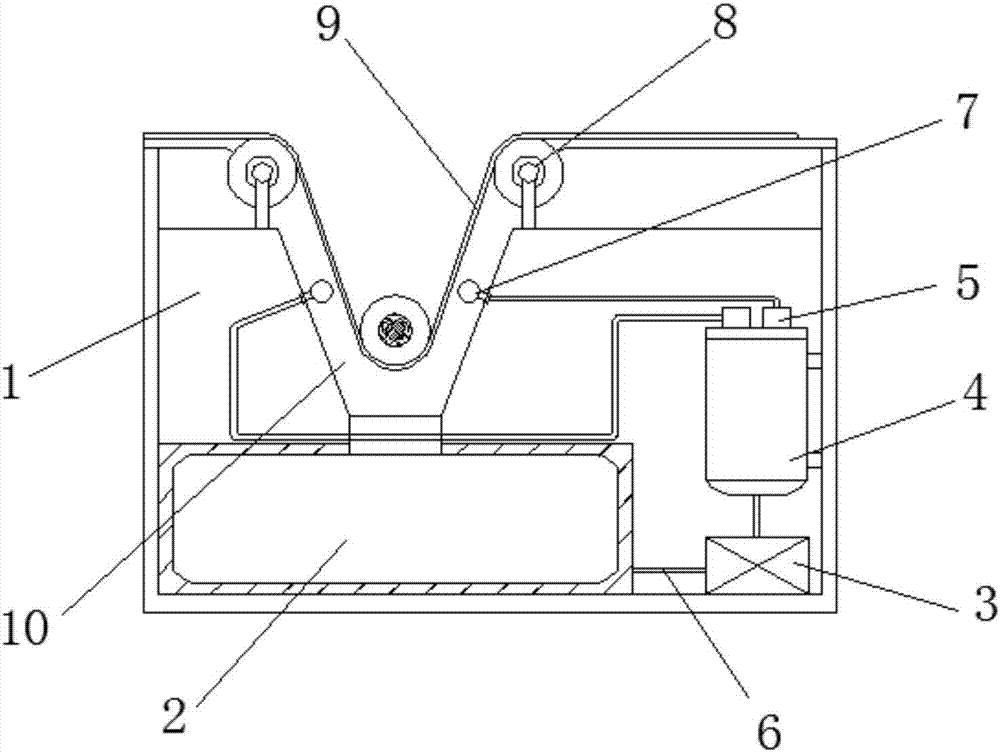

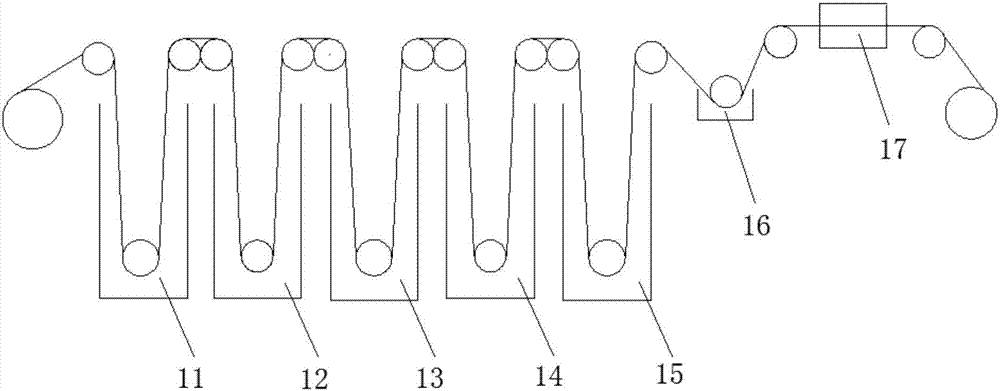

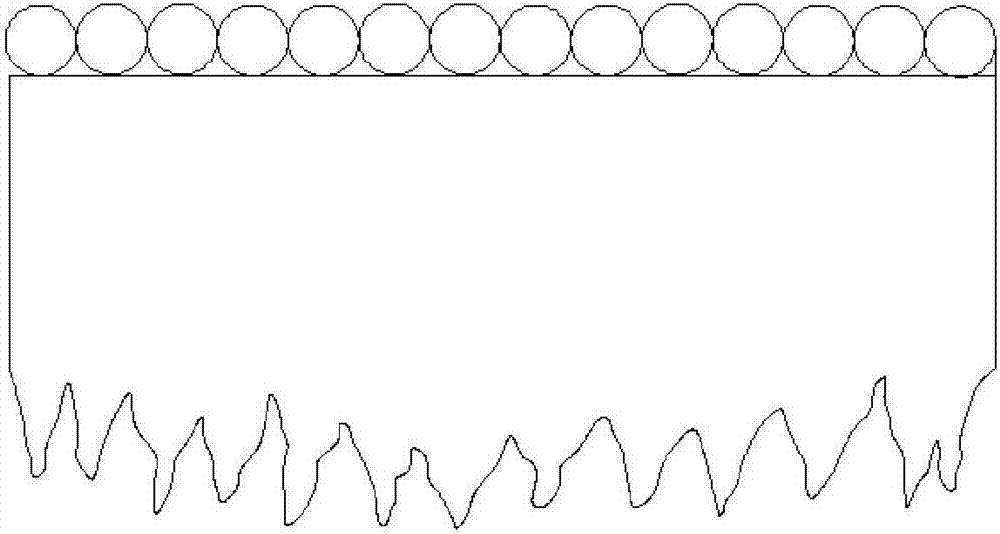

[0038]Slowly stir the sulfuric acid and water to make the concentration reach 300g / L, and the temperature is 60°C. The temperature will increase after the contact between water and sulfuric acid, so pay attention to the temperature during the stirring process to prevent danger caused by excessive temperature. The stirring time is 2min. Cool the mixture of water and sulfuric acid in the liquid storage tank 2, the cooling temperature is 20°C, and the cooling time is 3 minutes, then add hydrogen peroxide and hydrochloric acid into the liquid storage tank 2, the concentration of hydrogen peroxide is 90g / L, and the concentration of hydrochloric acid is 40g / L, the mixture of hydrogen peroxide and hydrochloric acid, water and sulfuric acid in the storage tank 2 will form a slightly turbid liquid after dissolution, the temperature is 30°C, the slightly turbid liquid is pumped to the filter 4, and the micro turbid liquid filtered by the filter 4 The turbid liquid flows into the spray pi...

Embodiment 2

[0040] Slowly stir the sulfuric acid and water to make the concentration reach 350g / L, the temperature is 70°C, the temperature will increase after the contact between water and sulfuric acid, so pay attention to the temperature during the stirring process, to prevent the danger caused by excessive temperature, the stirring time is 3min, Cool the mixture of water and sulfuric acid in the liquid storage tank 2, the cooling temperature is 22°C, and the cooling time is 8 minutes, then add hydrogen peroxide and hydrochloric acid into the liquid storage tank 2, the concentration of hydrogen peroxide is 80g / L, and the concentration of hydrochloric acid is 30g / L, the mixture of hydrogen peroxide and hydrochloric acid, water and sulfuric acid in storage tank 2, dissolves to form a slightly turbid liquid, the temperature is 30°C, the slightly turbid liquid is pumped to the filter 4, and the micro turbid liquid filtered by the filter 4 The turbid liquid flows into the spray pipe 7, the c...

Embodiment 3

[0042] Add water into the liquid storage tank 2, then add sulfuric acid into the liquid storage tank 2 and stir. The concentration of sulfuric acid is 330g / L, and the temperature is 66°C. The temperature will increase after the contact between water and sulfuric acid, so pay attention to the temperature during the stirring process To prevent danger caused by excessive temperature, cool the mixture of water and sulfuric acid in the liquid storage tank 2, the cooling temperature is 33°C, and the cooling time is 7 minutes, then add hydrogen peroxide and hydrochloric acid into the liquid storage tank 2, the hydrogen peroxide concentration The concentration of hydrochloric acid is 75g / L, the concentration of hydrochloric acid is 36g / L, the mixture of hydrogen peroxide and hydrochloric acid, water and sulfuric acid in storage tank 2 will form a slightly turbid liquid after dissolution, the temperature is 32°C, and the slightly turbid liquid is pumped to filter 4 , the slightly turbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com