PCB cleaning line

A PCB board and cleaning line technology, applied in the cleaning/polishing of conductive patterns, secondary treatment of printed circuits, etc., can solve the problem of easy residual grease and oxides on the surface of PCB boards, oxides, fingerprints, complex PCB board manufacturing processes, and single cleaning methods. and other problems, to achieve a thorough and comprehensive cleaning effect, improve the browning effect, and improve the overall effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

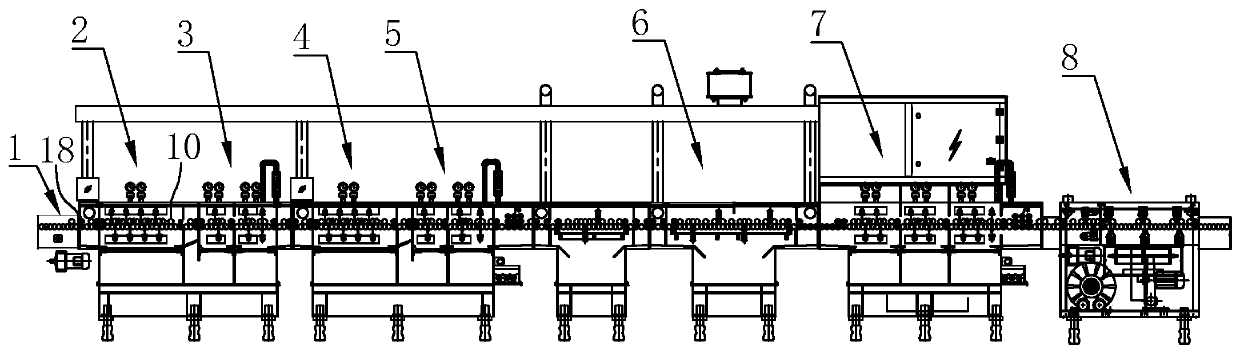

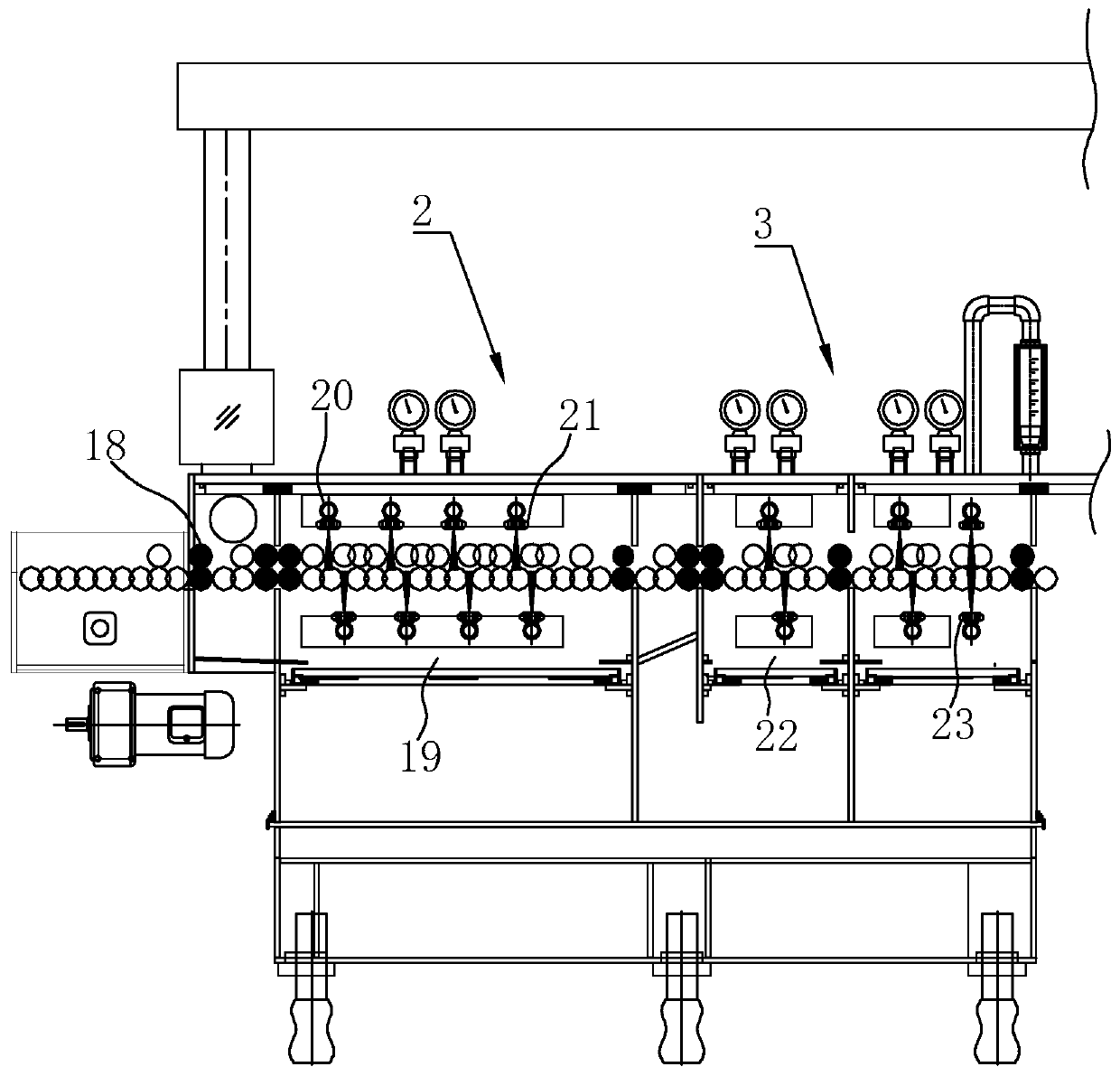

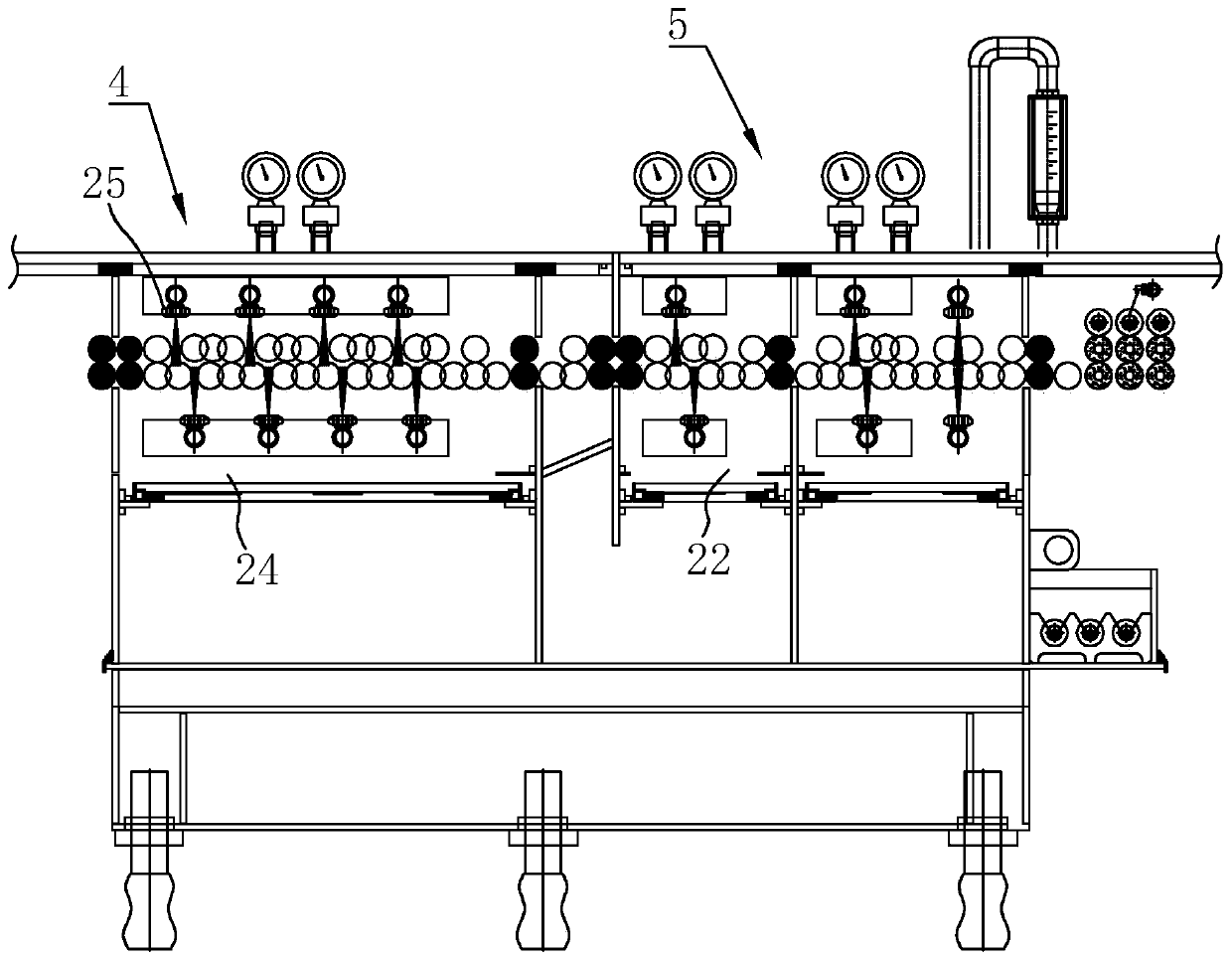

[0038] A PCB board cleaning line, such as figure 1As shown, it includes a strip-shaped conveying platform 1, and the PCB board is placed on the conveying platform 1 and continuously transported towards it. On the conveying platform 1, an alkali cleaning device 2, a first water cleaning device 3, and an acid washing device 3 are sequentially arranged along the conveying direction. Washing device 4, second washing device 5, browning device 6, third washing device 7 and air-drying device 8, so that the operations of alkali washing, pickling, browning and air-drying are sequentially completed in the PCB board conveying process, to achieve PCB The board is more comprehensively and thoroughly cleaned, and the PCB board output from the end of the conveyor table 1 is in a dry state and can directly proceed to the next production process, which effectively improves pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com