Patents

Literature

35 results about "Vertex distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vertex distance is the distance between the back surface of a corrective lens, i.e. glasses (spectacles) or contact lenses, and the front of the cornea. Increasing or decreasing the vertex distance changes the optical properties of the system, by moving the focal point forward or backward, effectively changing the power of the lens relative to the eye. Since most refractions (the measurement that determines the power of a corrective lens) are performed at a vertex distance of 12-14 mm, the power of the correction may need to be modified from the initial prescription so that light reaches the patient's eye with the same effective power that it did through the phoropter or trial frame.

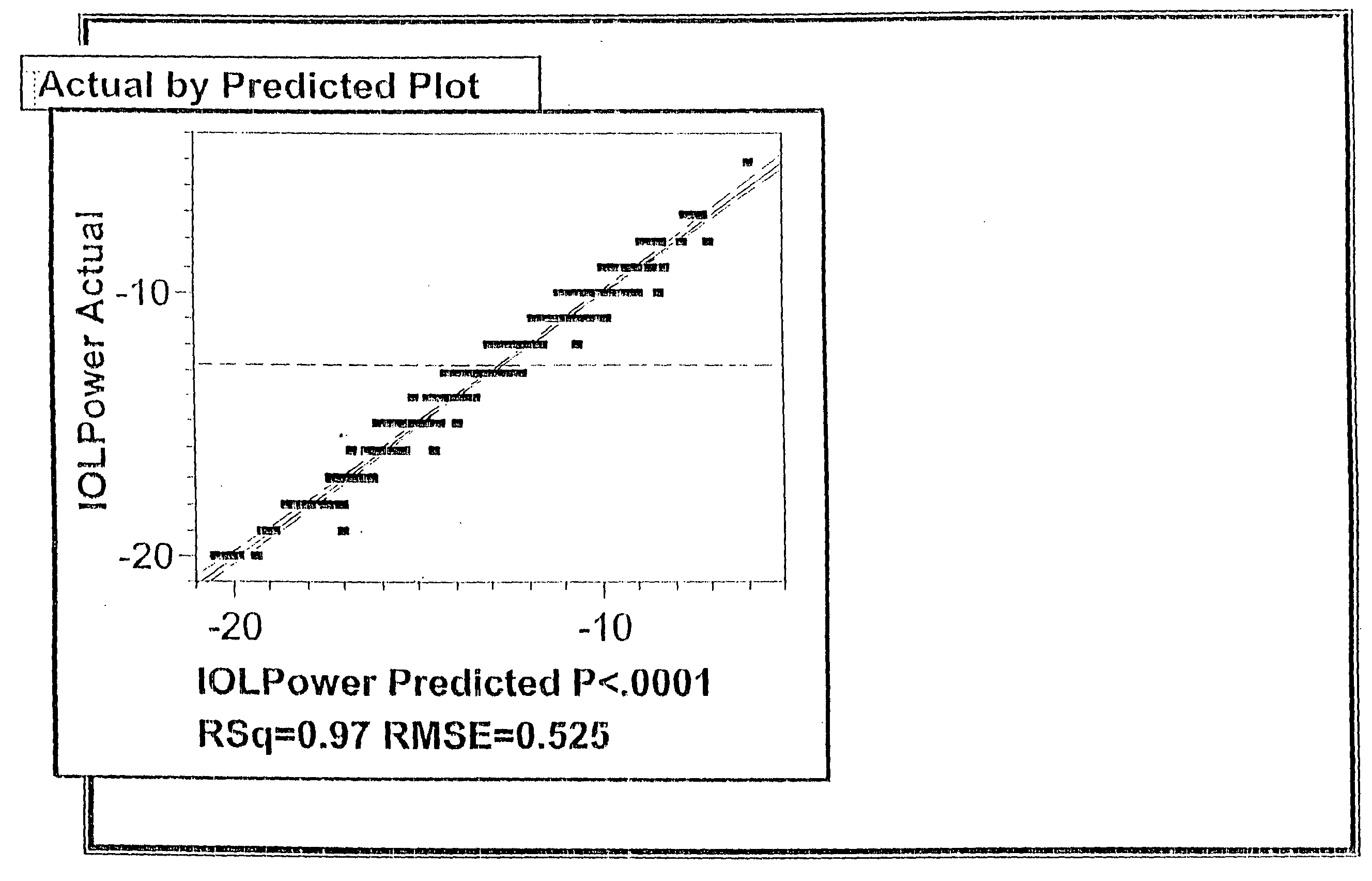

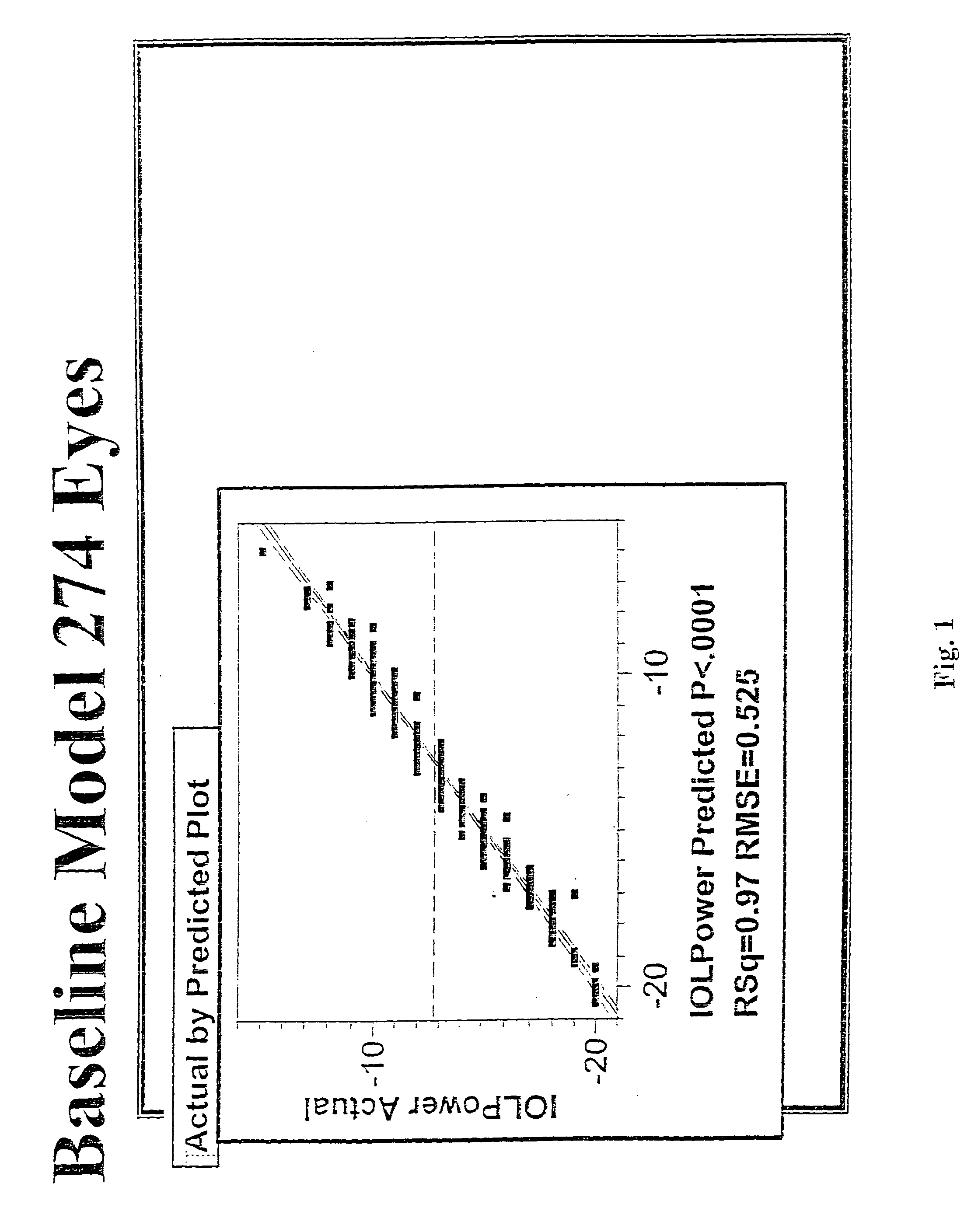

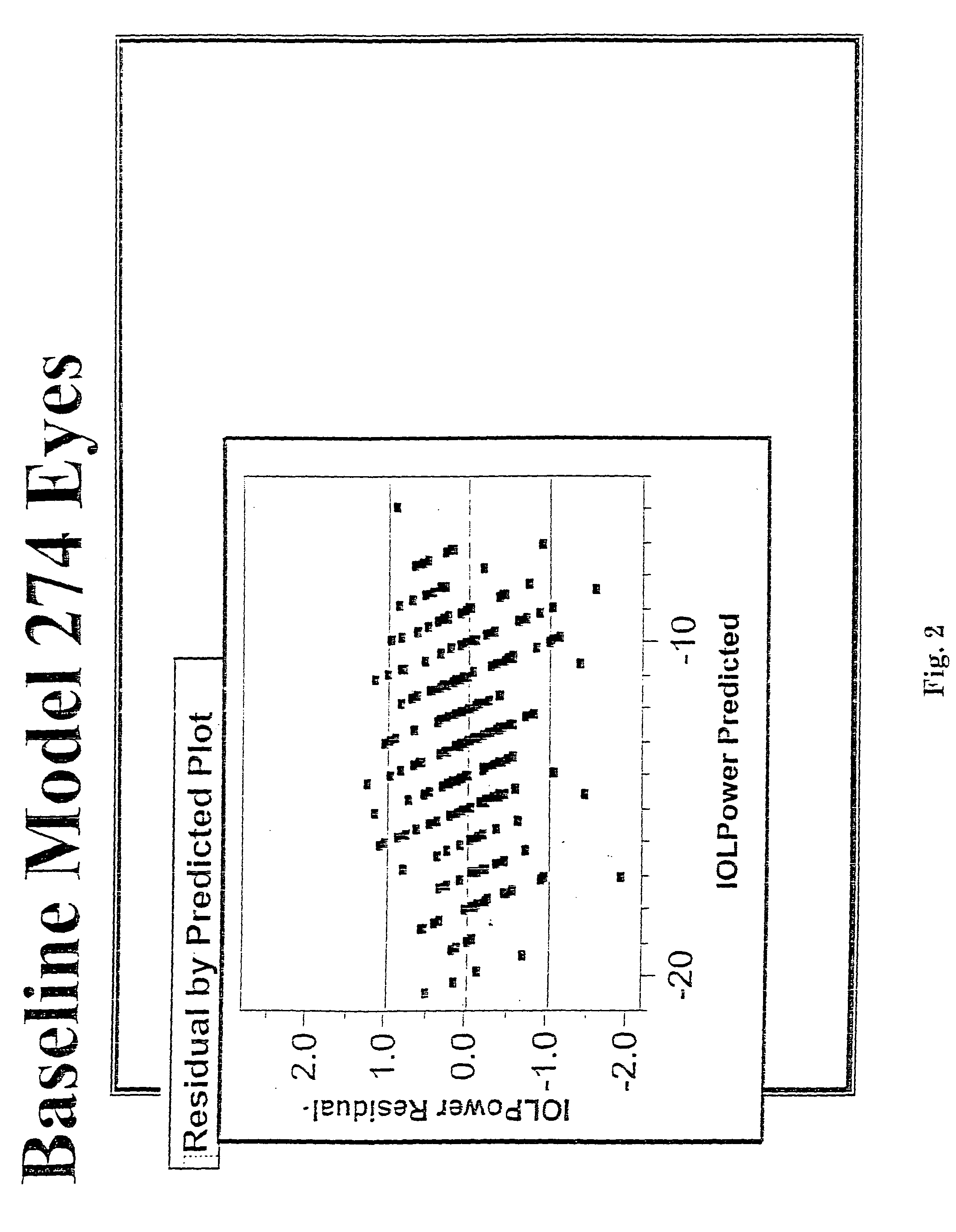

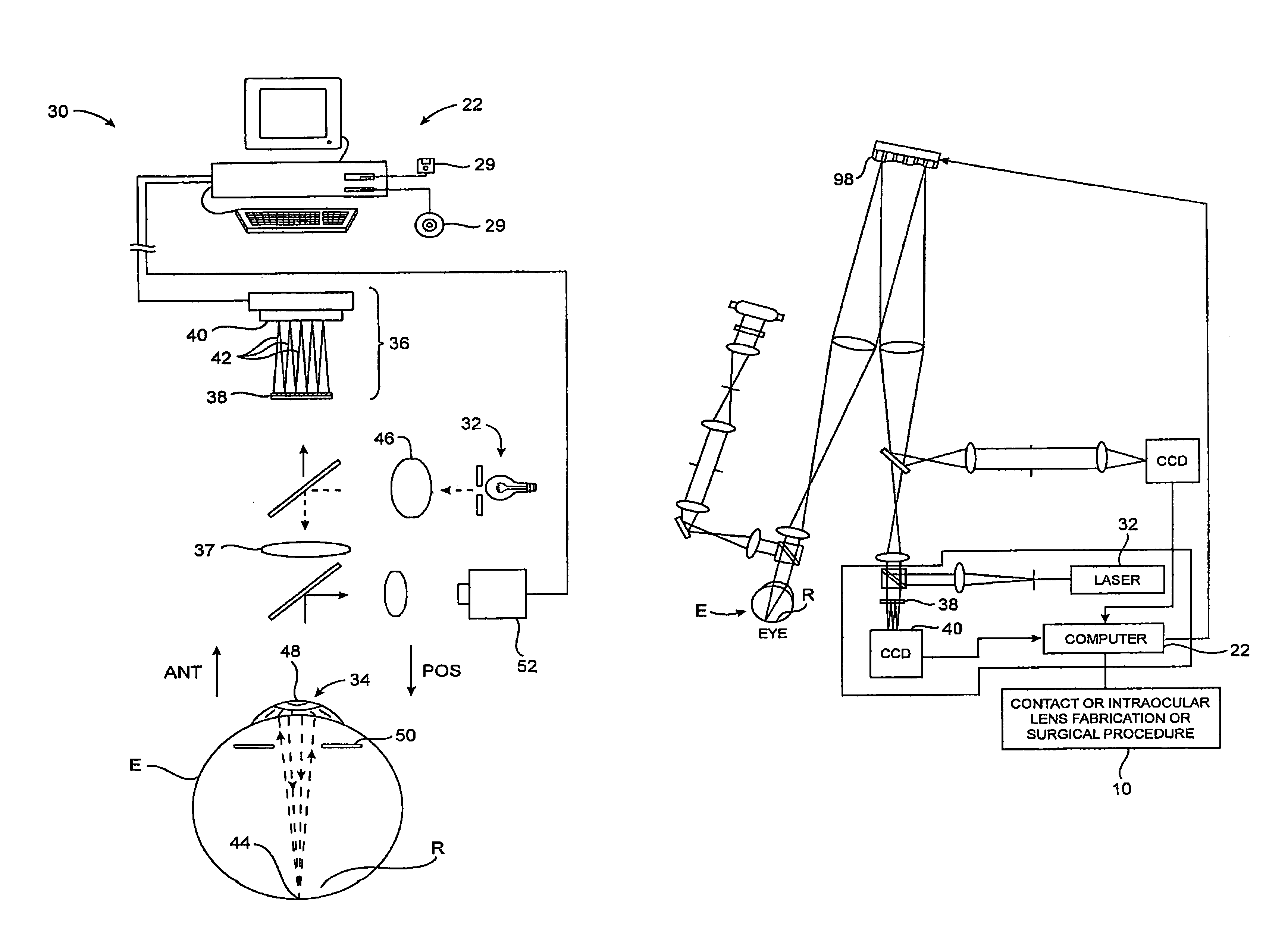

Method for determining the power of an intraocular lens used for the treatment of myopia

InactiveUS7044604B1Improve predictabilityCorrection of myopiaEye diagnosticsIntraocular lensCorneal curvatureIntraocular lens

A method of deriving a prediction model and calculating a predicted lens power to provide a desired post-operative spherical equivalent to correct myopia in a phakic eye of a patient using an intraocular lens includes measuring and determining the predictive significance of certain pre-operative characteristics of the eye, including cycloplegic and manifest spherical equivalent, vertex distance, anterior chamber depth, axial length, and keratometry. The prediction model is derived using multiple regression analysis on the pre-operative and post operative data. Measured data corresponding to a particular patient is used in the lens power prediction model to calculate the predicted lens power for implantation in the patient.

Owner:ARROWSMITH PETER N

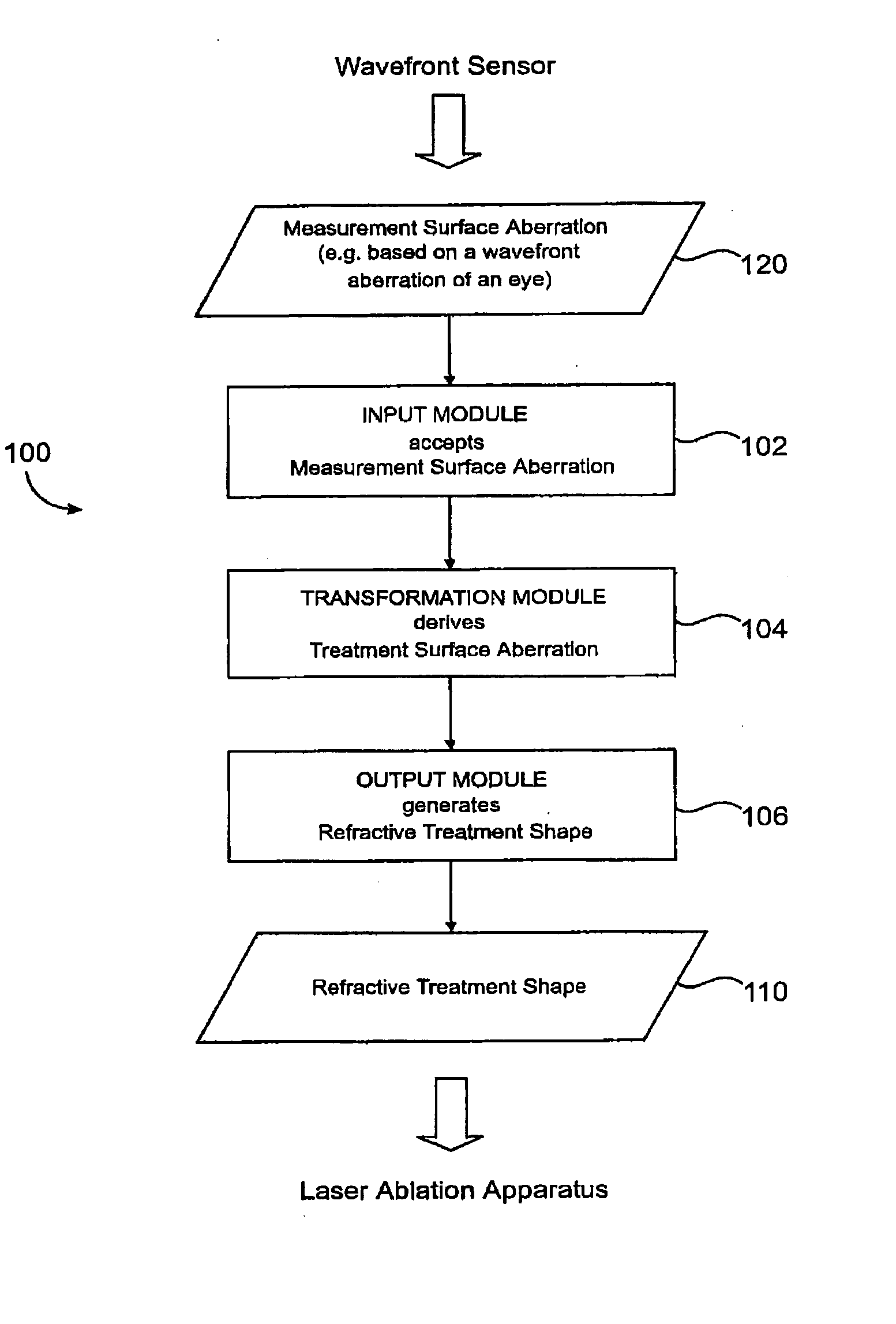

Transformation methods of wavefront maps from one vertex distance to another

The present invention provides methods, systems and software for scaling optical aberration measurements of optical systems. In one embodiment, the present invention provides a method of reconstructing optical tissues of an eye. The method comprises transmitting an image through the optical tissues of the eye. Aberration data from the transmitted image is measured across the optical tissues of the eye at a first plane. A conversion algorithm is applied to the data, converting it to corrective optical power data that can be used as a basis for constructing a treatment for the eye at a second plane.

Owner:AMO MFG USA INC

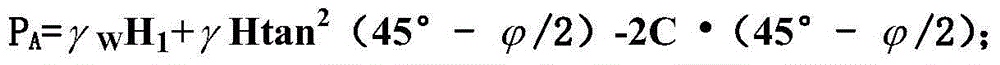

Drag reduction method of thixotropic slurry

ActiveCN104534167AReduce frictional resistanceImprove drag reduction efficiencyPipe laying and repairCarboxymethyl celluloseSlurry

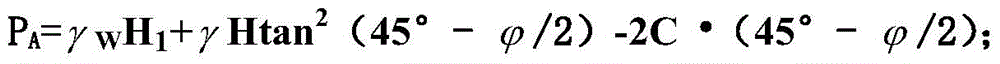

The invention discloses a drag reduction method of thixotropic slurry, and belongs to the technical field of civil engineering. The method includes the steps: firstly, preparing the thixotropic slurry for drag reduction; secondly, placing stirred thixotropic slurry into a slurry storage tank, forming a grouting hole and connecting a grouting pipeline; thirdly, calculating grouting pressure and selecting a grouting pump; finally, performing grouting. The thixotropic slurry comprises sodium bentonite, carboxymethyl cellulose, sodium carbonate, clean water and an appropriate amount of admixture. Frictional drag of a pipe and soil is decreased by a grouting process, the vertex distance can be increased by 40%-70% after lubrication and drag reduction by the grouting process, drag of a top pipe in work can be effectively reduced, the top pipe with a large caliber and a long distance can continuously extend, and the drag reduction method has the advantages of low cost, easiness in technical implementation and high drag reduction efficiency.

Owner:CHINA MCC17 GRP

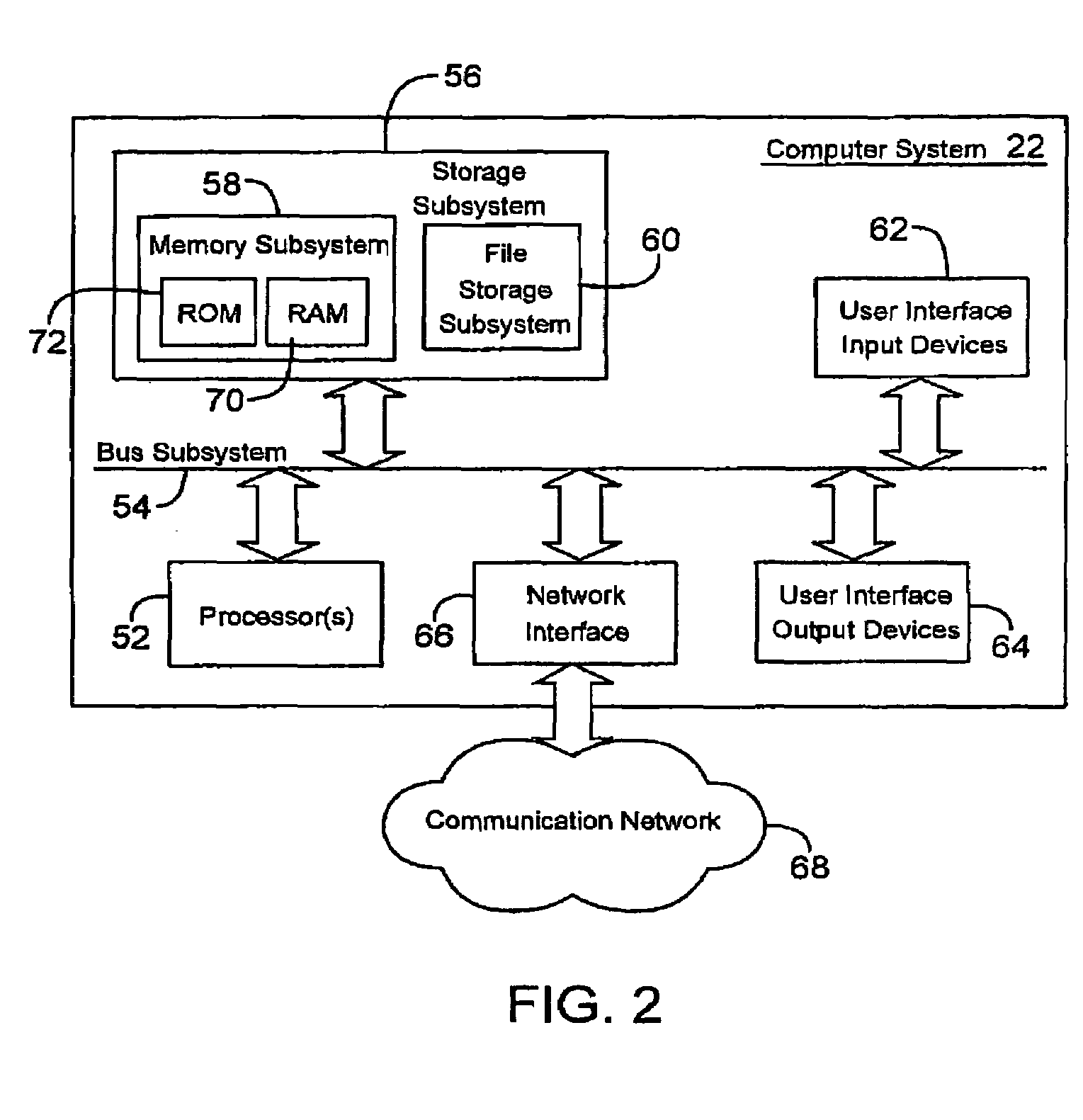

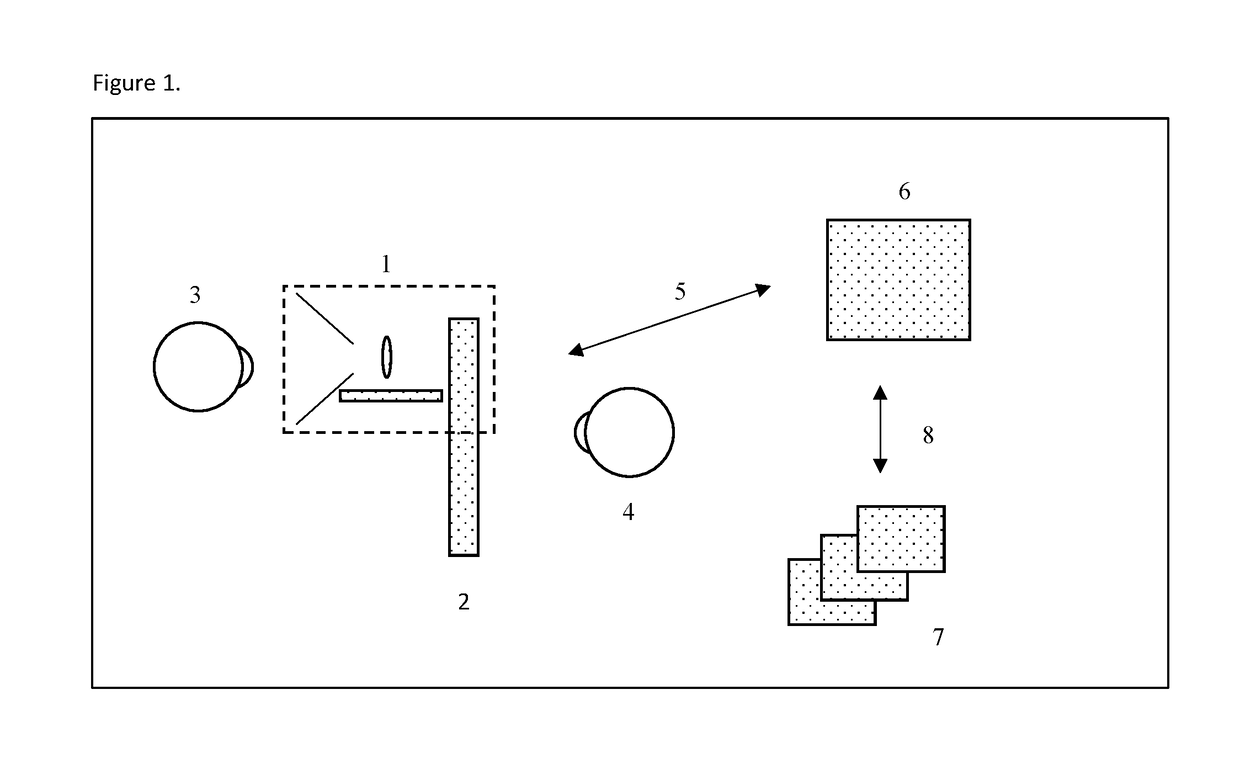

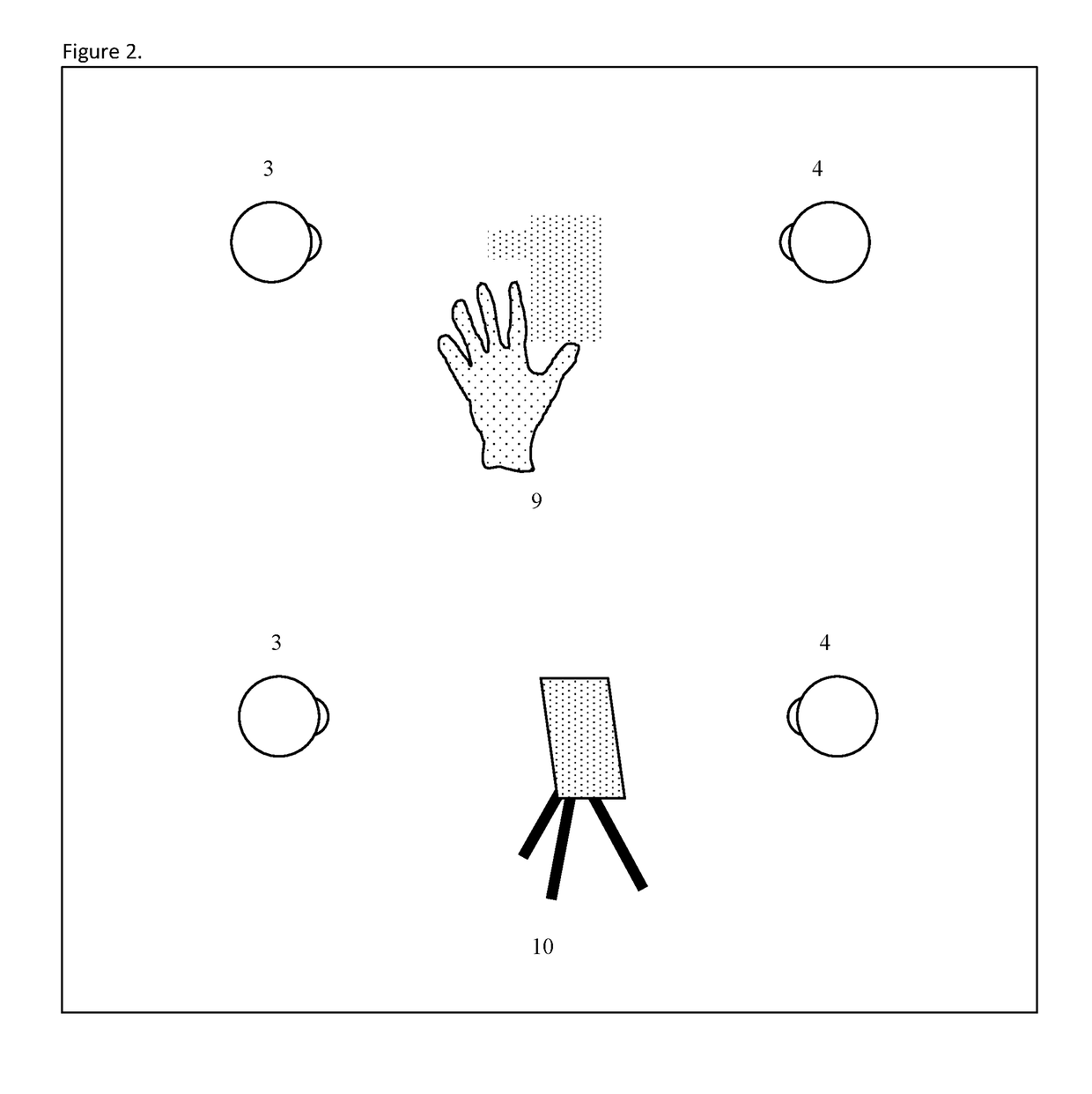

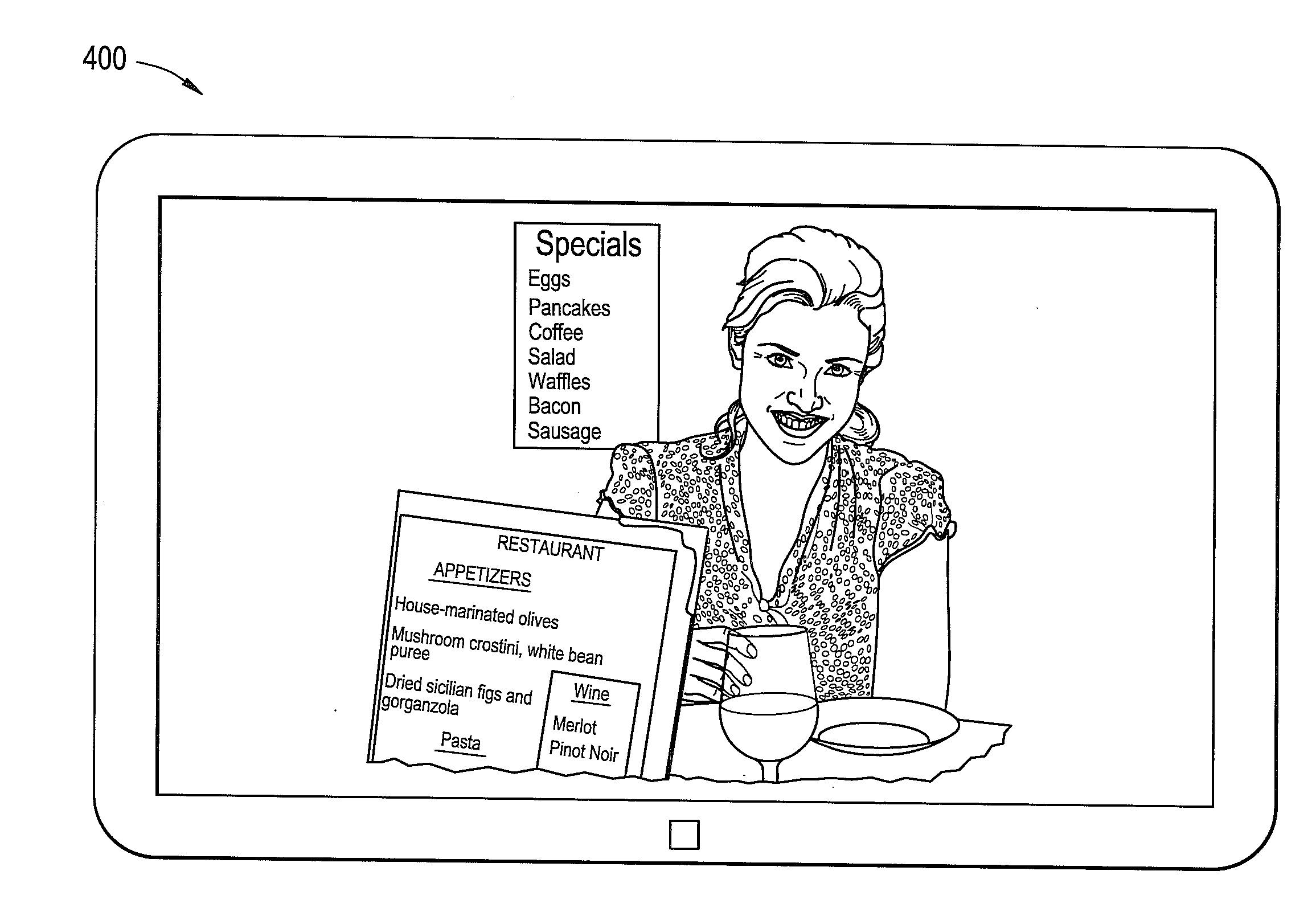

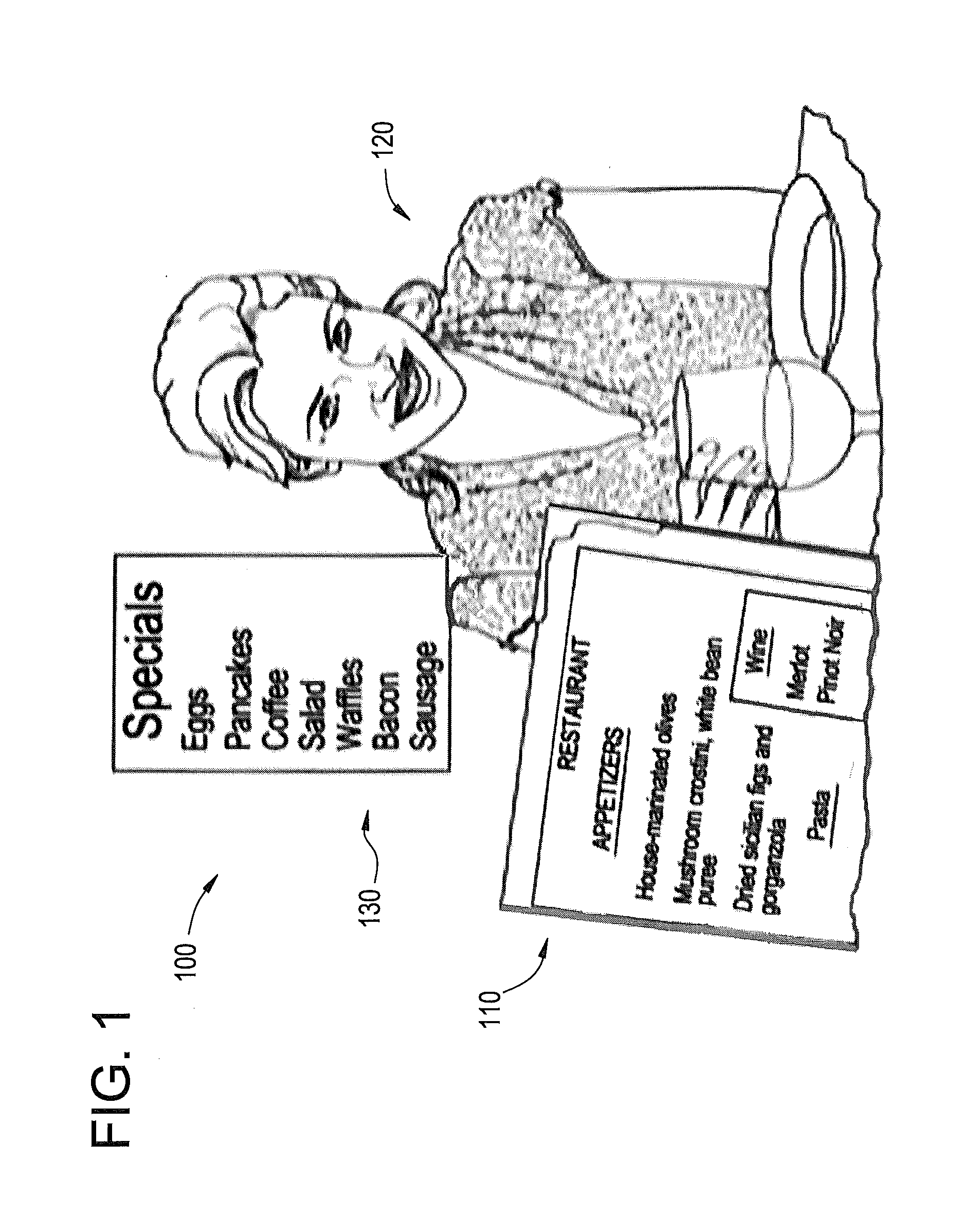

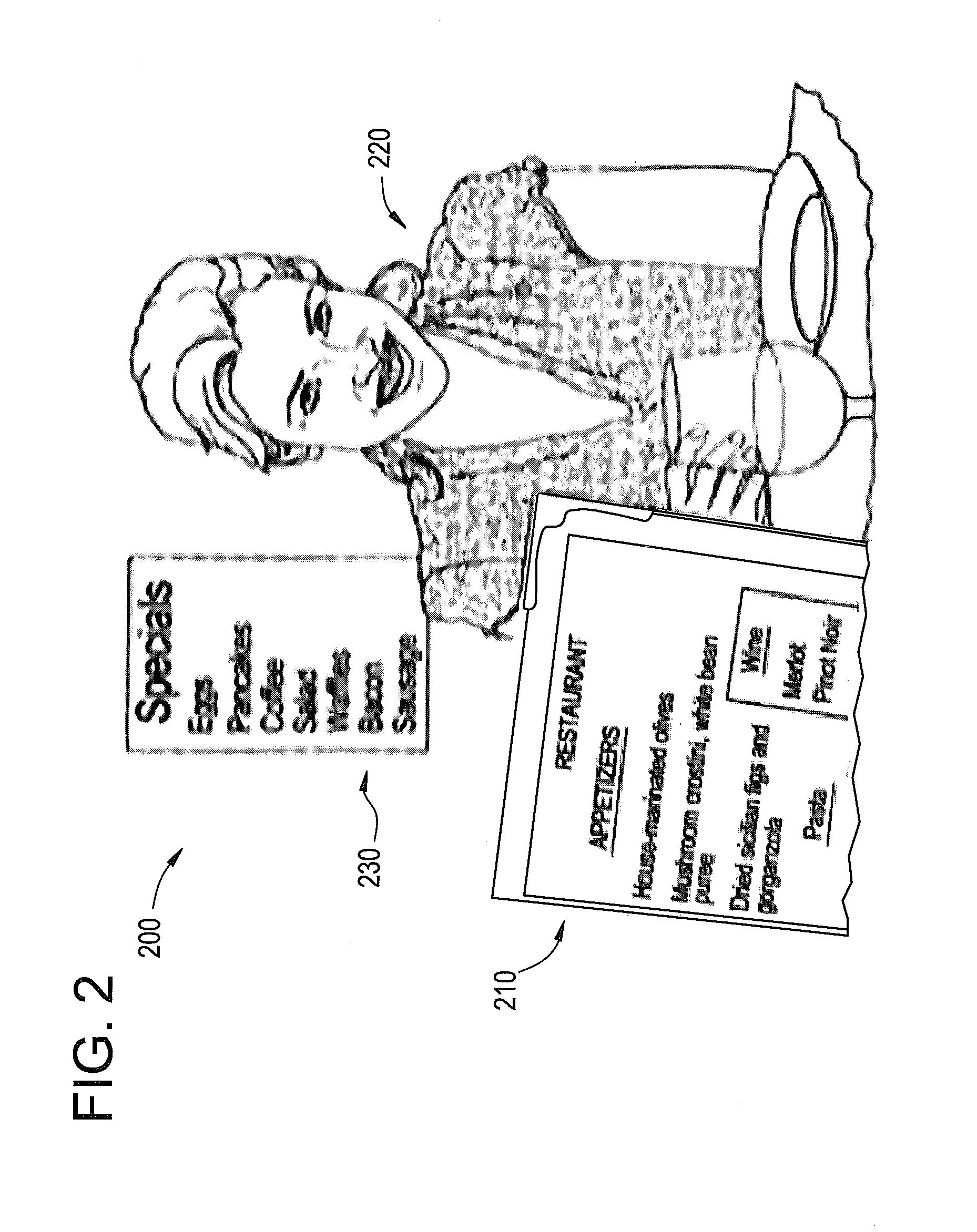

System, Method and Apparatus For Enabling Corneal Topography Mapping by Smartphone

An apparatus for enabling corneal topography includes an attachment to align a placido disc illumination system with a camera of a mobile communication device. The placido disc illumination system generates concentric rings and reflects the concentric rings off a cornea. A portion of the reflected concentric rings are utilized to confirm vertex distance. The apparatus further comprises a memory, a processor, and computer-readable instructions in a mobile communication device. The camera captures an image of reflected concentric rings and communicates the captured image of the reflected concentric rings to an external computing device. A method for performing corneal topography utilizes a mobile computing and / or communication device, projects a plurality of peripheral concentric rings onto a subject's cornea and projects center rings onto the subject's cornea. The method further includes capturing, via a smartphone camera, an image of the projected peripheral concentric rings and the center rings.

Owner:INTELLIGENT DIAGNOSTICS LLC

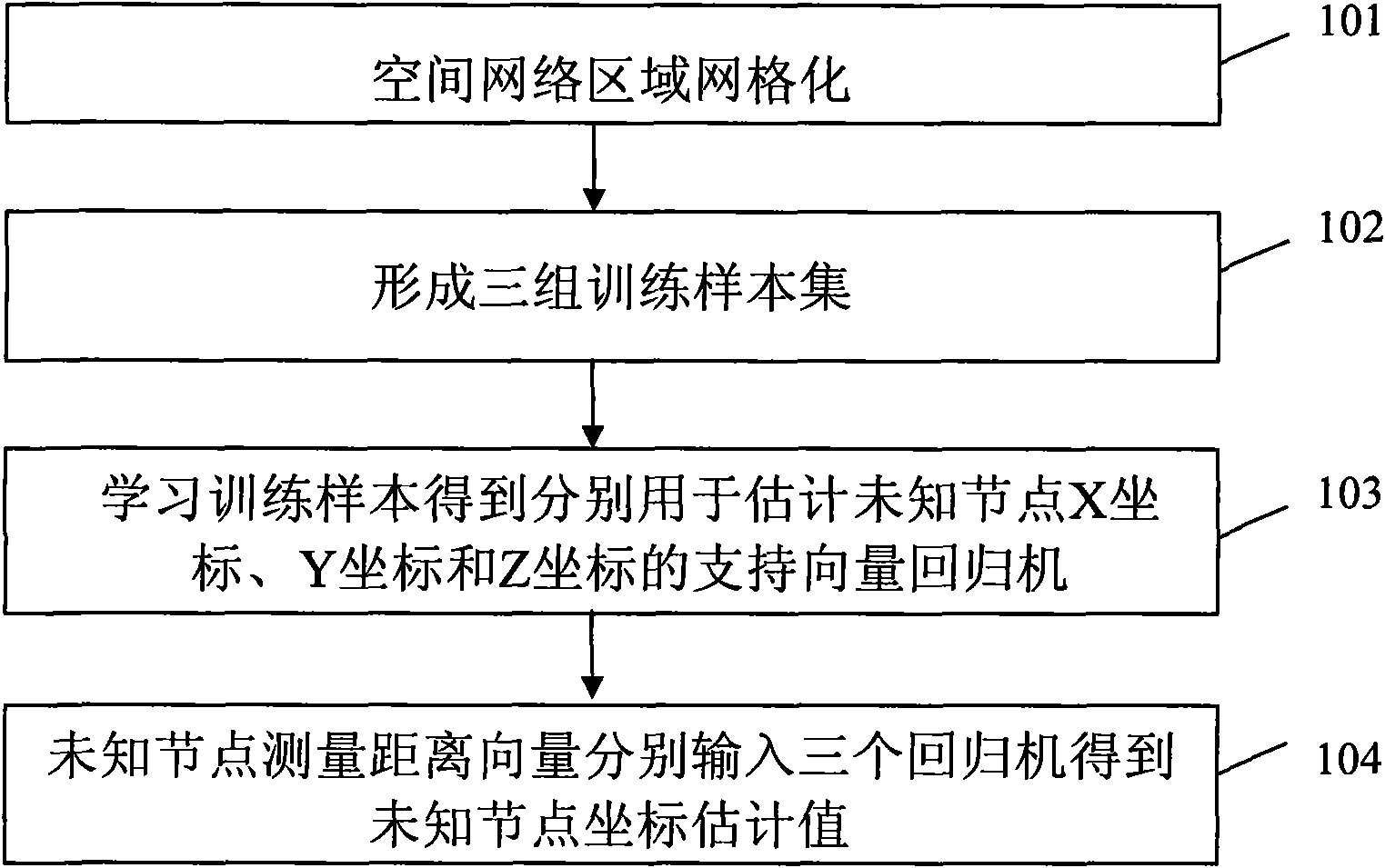

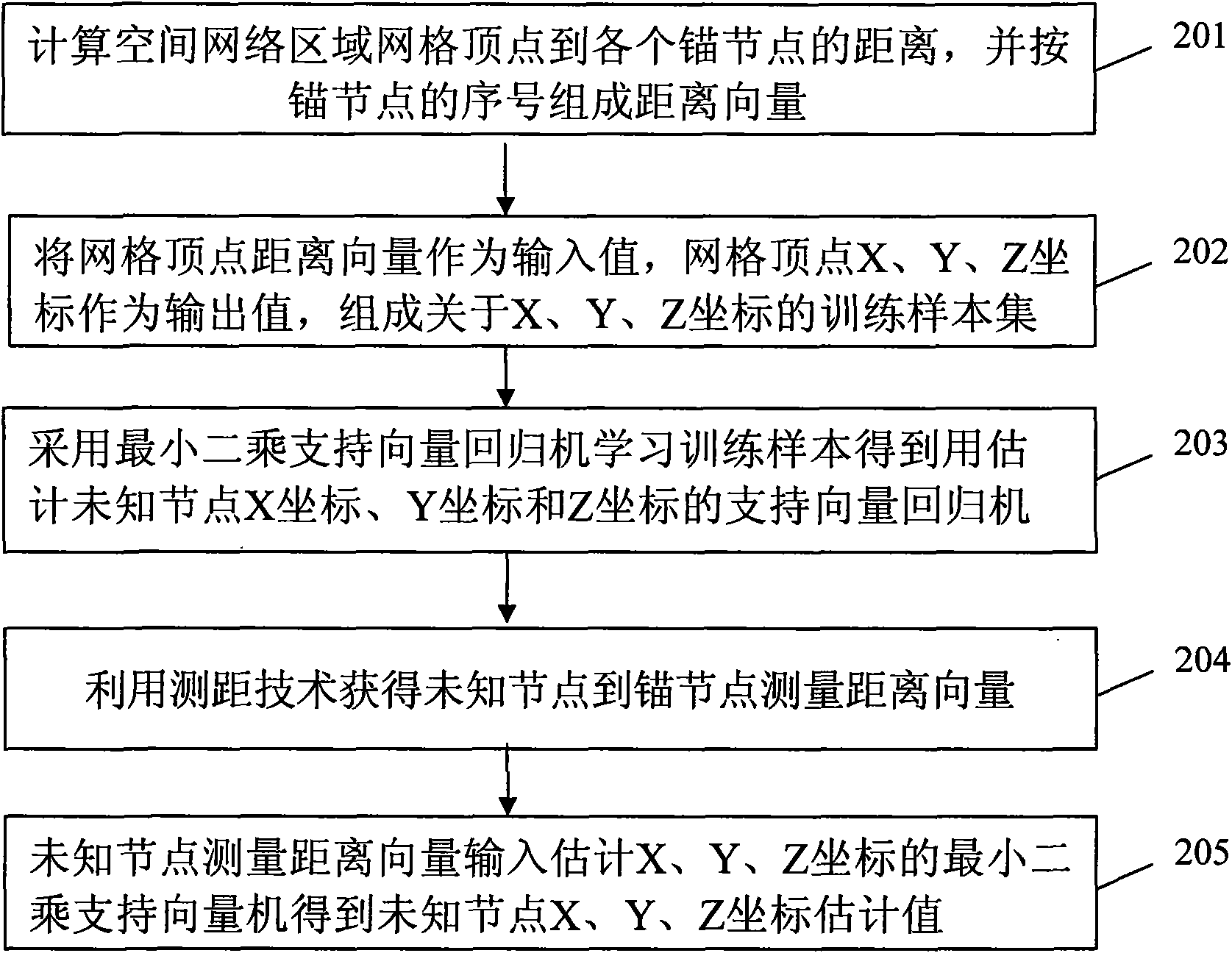

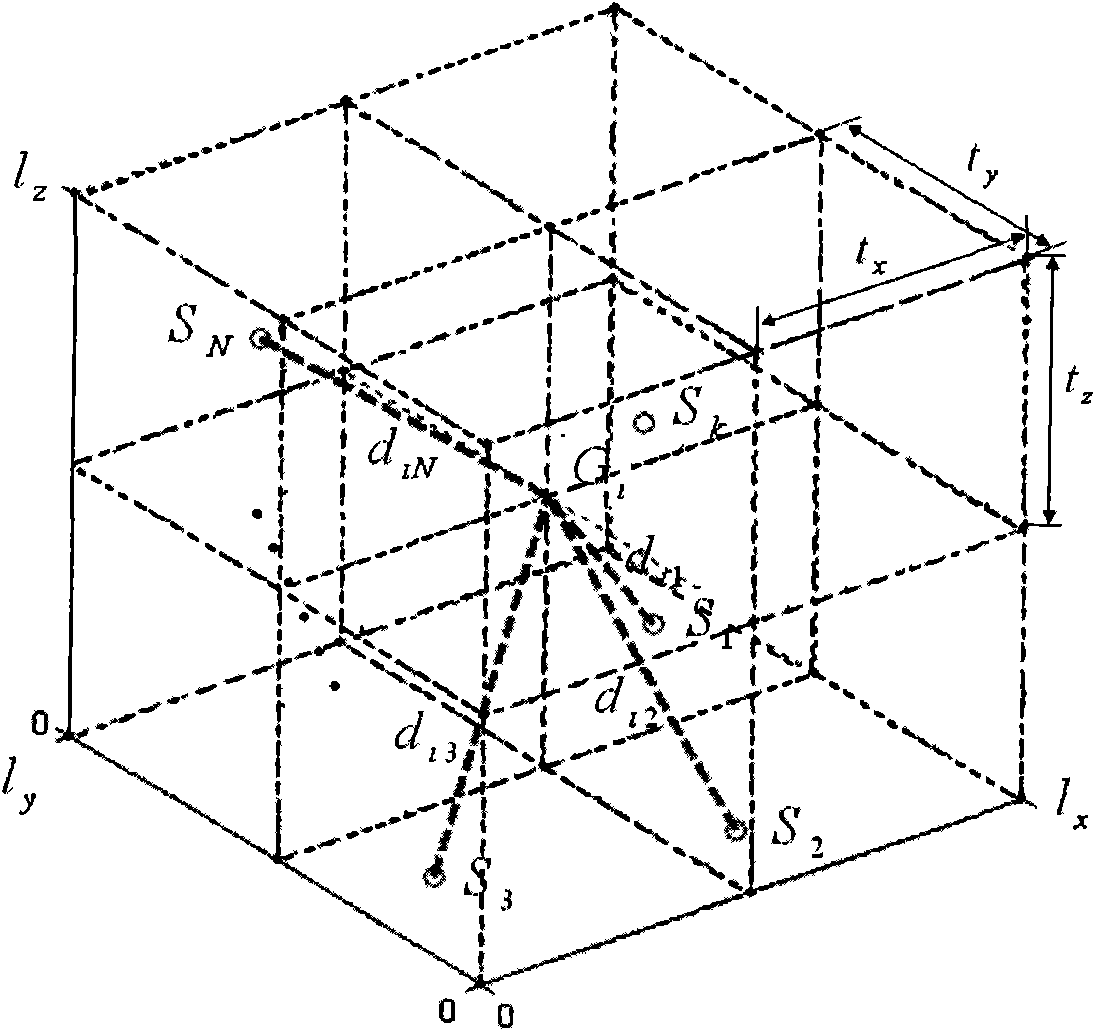

Method for three-dimensionally positioning network node of wireless sensor

InactiveCN101561495AInhibition effectImprove 3D positioning accuracyNetwork topologiesPosition fixationAlgorithmWireless sensor networking

The invention discloses a method for three-dimensionally positioning a network node of a wireless sensor, which comprises the following steps: performing meshing on a space network region, calculating the distance between a mesh vertex and each anchor node and forming distance vectors; forming three groups of training sample sets according to the mesh vertex distance vectors and mesh vertex three-dimensional coordinates; obtaining a support vector regression machine for estimating an X coordinate, a Y coordinate and a Z coordinate of an unknown node respectively according to radial basis kernel function and a study training sample of a least squares support vector regression machine; and forming distance vectors by measuring distances between the unknown node and each anchor node, and respectively inputting the distance vectors into three regression machines to obtain a three-dimensional coordinate estimation value of the unknown node. Through the method, the influence on the node positioning accuracy by distance measuring noises of the unknown node and the anchor nodes can be greatly inhibited, and the three-dimensional positioning accuracy of the nodes is obviously improved.

Owner:长讯通信服务有限公司

Transformation methods of wavefront maps from one vertex distance to another

The present invention provides methods, systems and software for scaling optical aberration measurements of optical systems. In one embodiment, the present invention provides a method of reconstructing optical tissues of an eye. The method comprises transmitting an image through the optical tissues of the eye. Aberration data from the transmitted image is measured across the optical tissues of the eye at a first plane. A conversion algorithm is applied to the data, converting it to corrective optical power data that can be used as a basis for constructing a treatment for the eye at a second plane.

Owner:AMO MFG USA INC

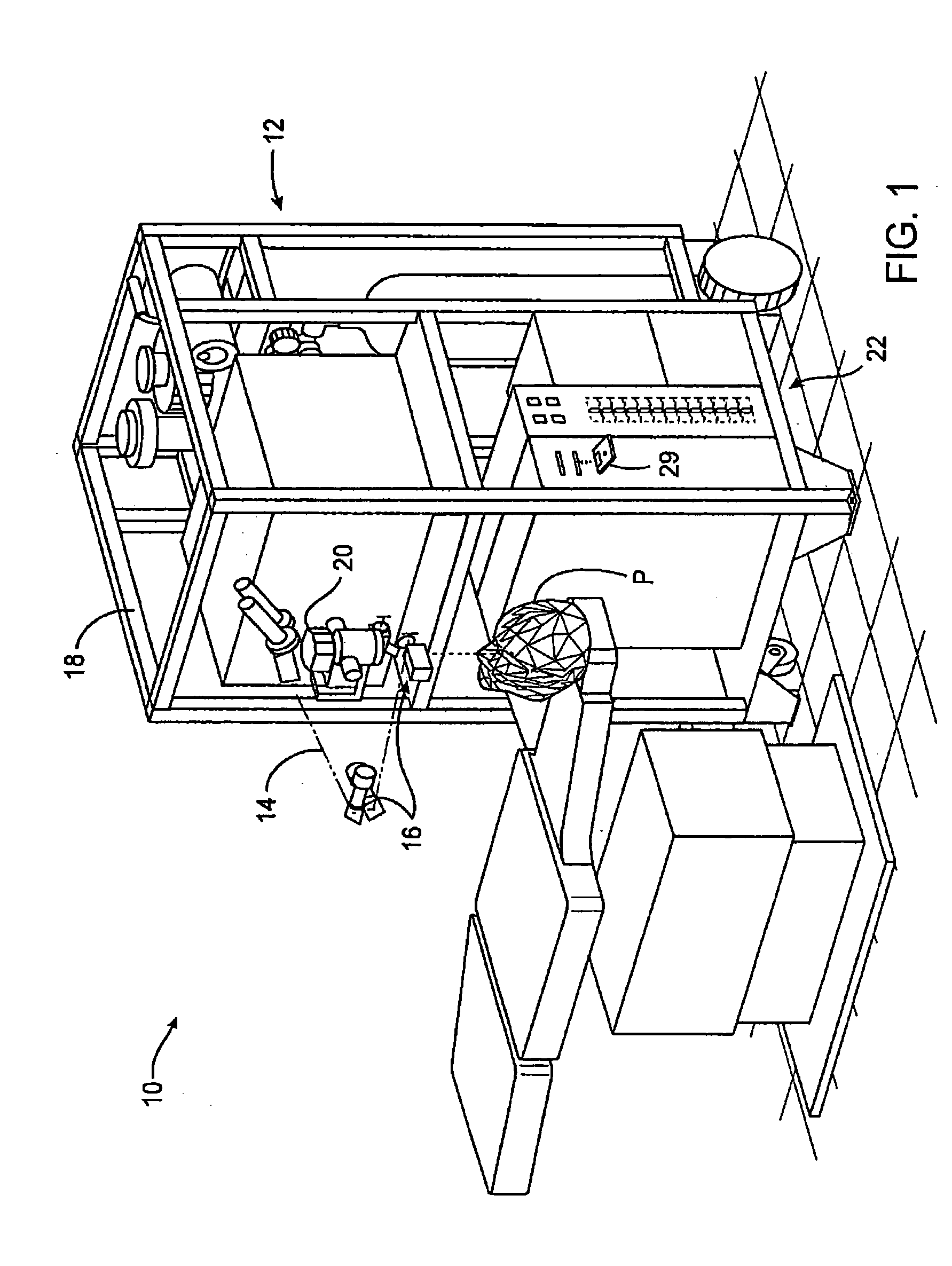

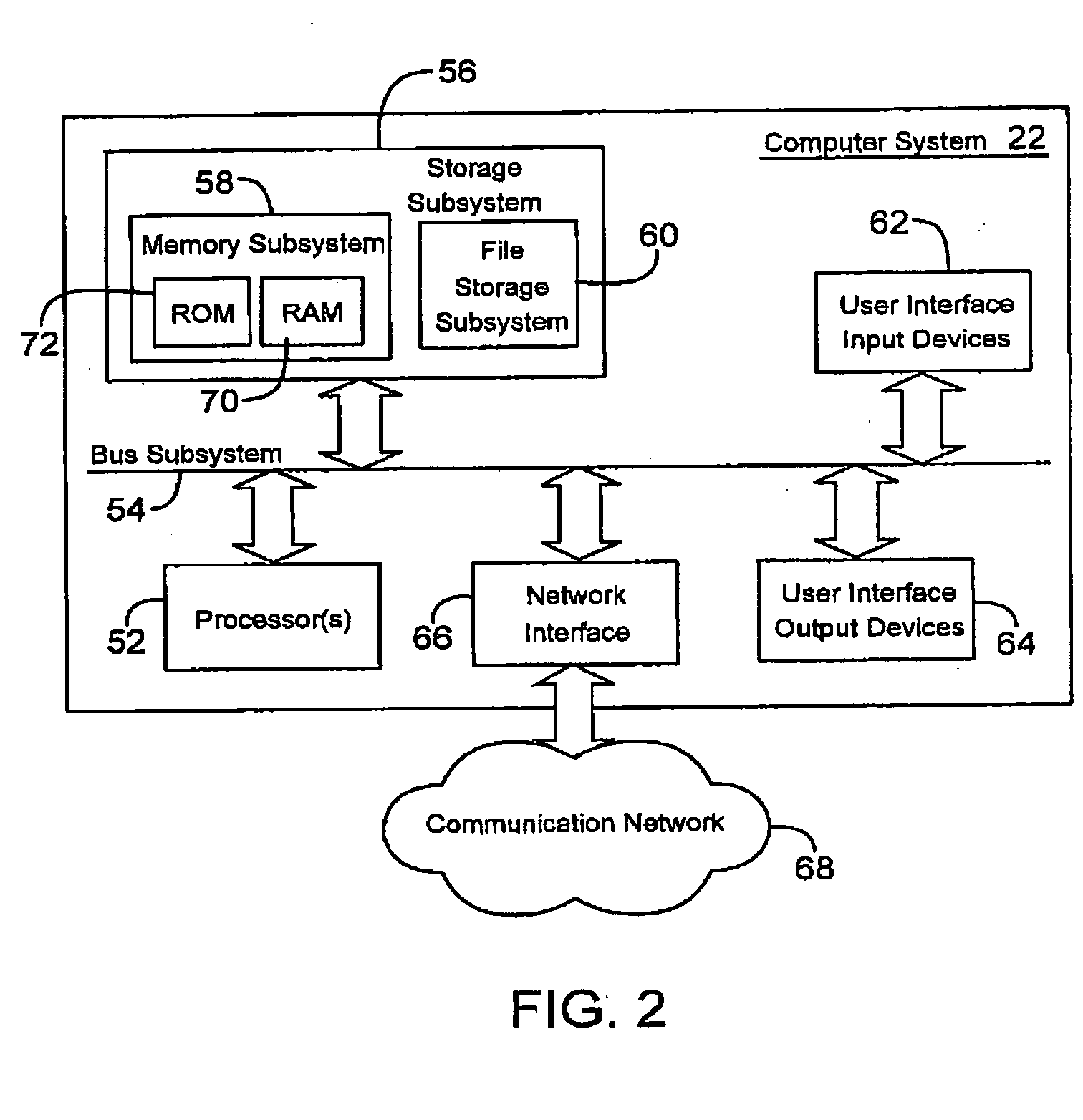

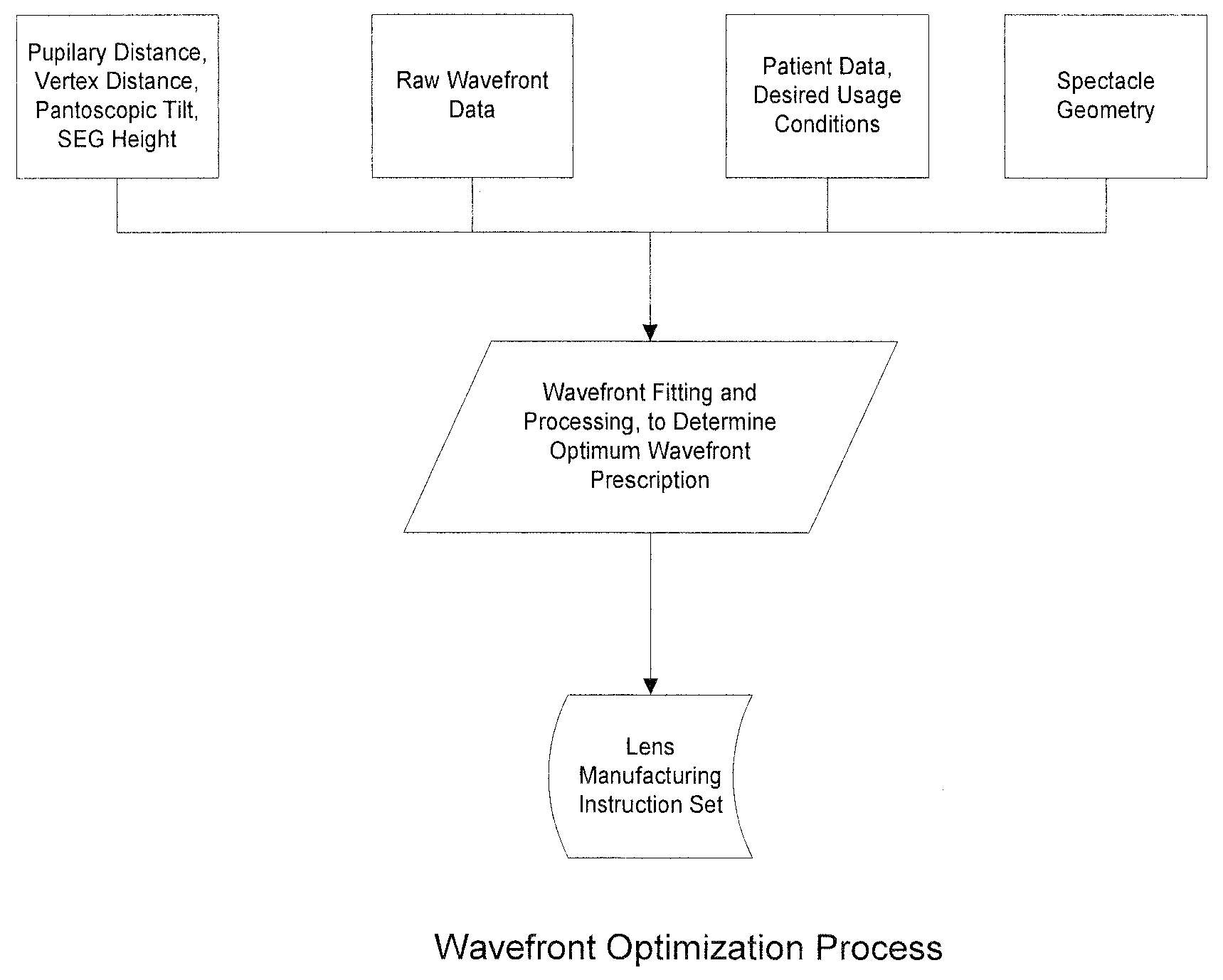

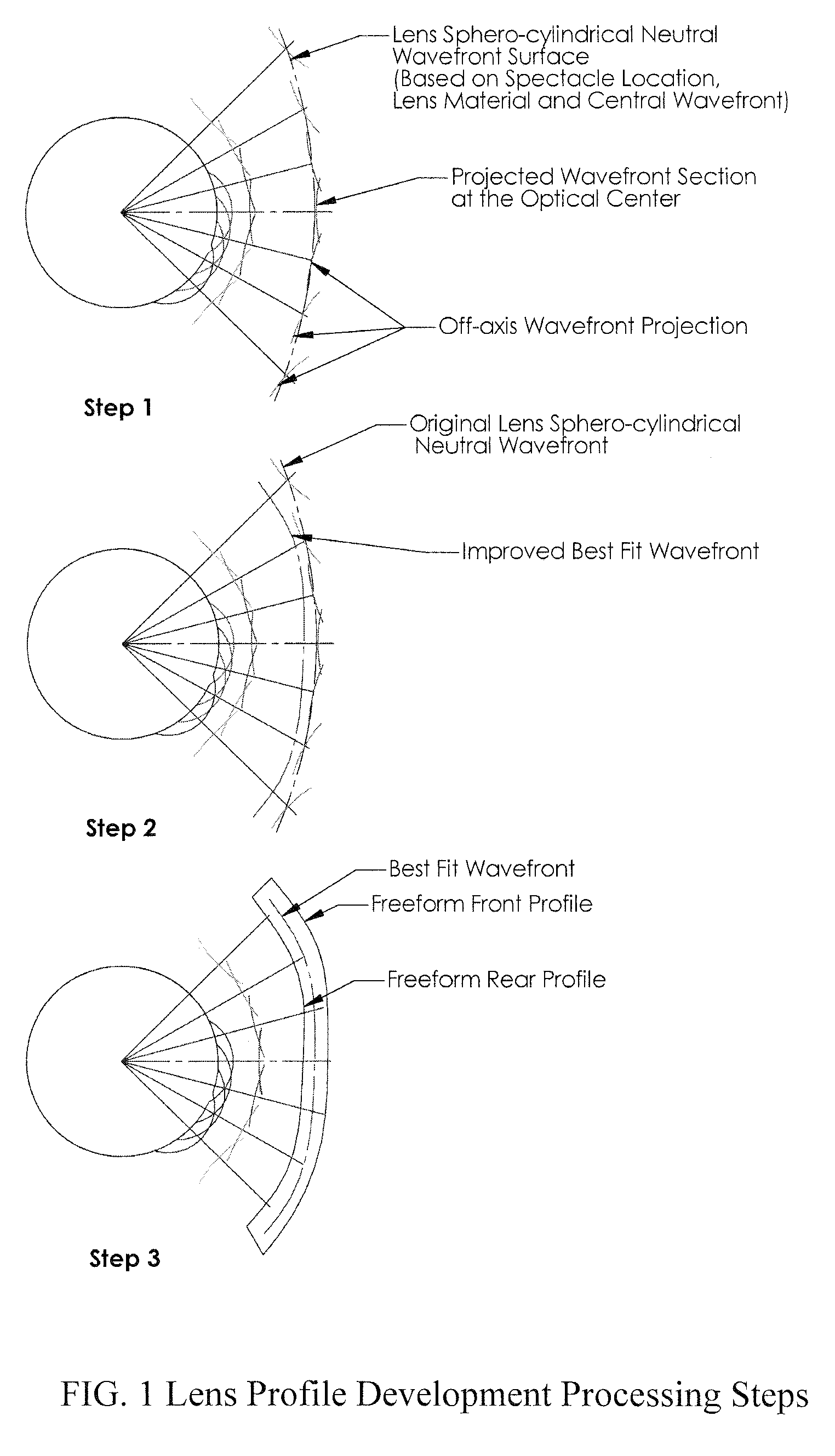

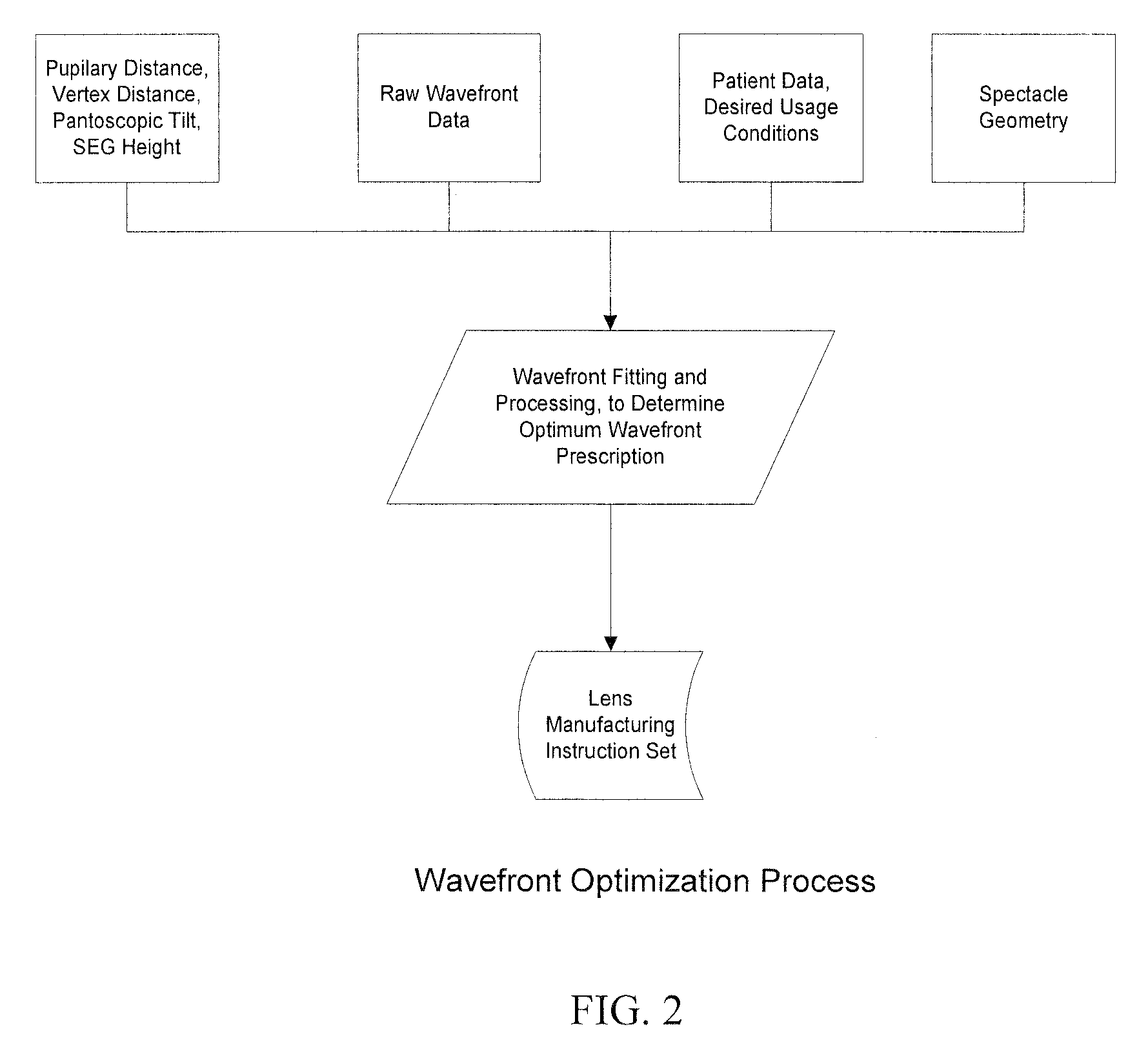

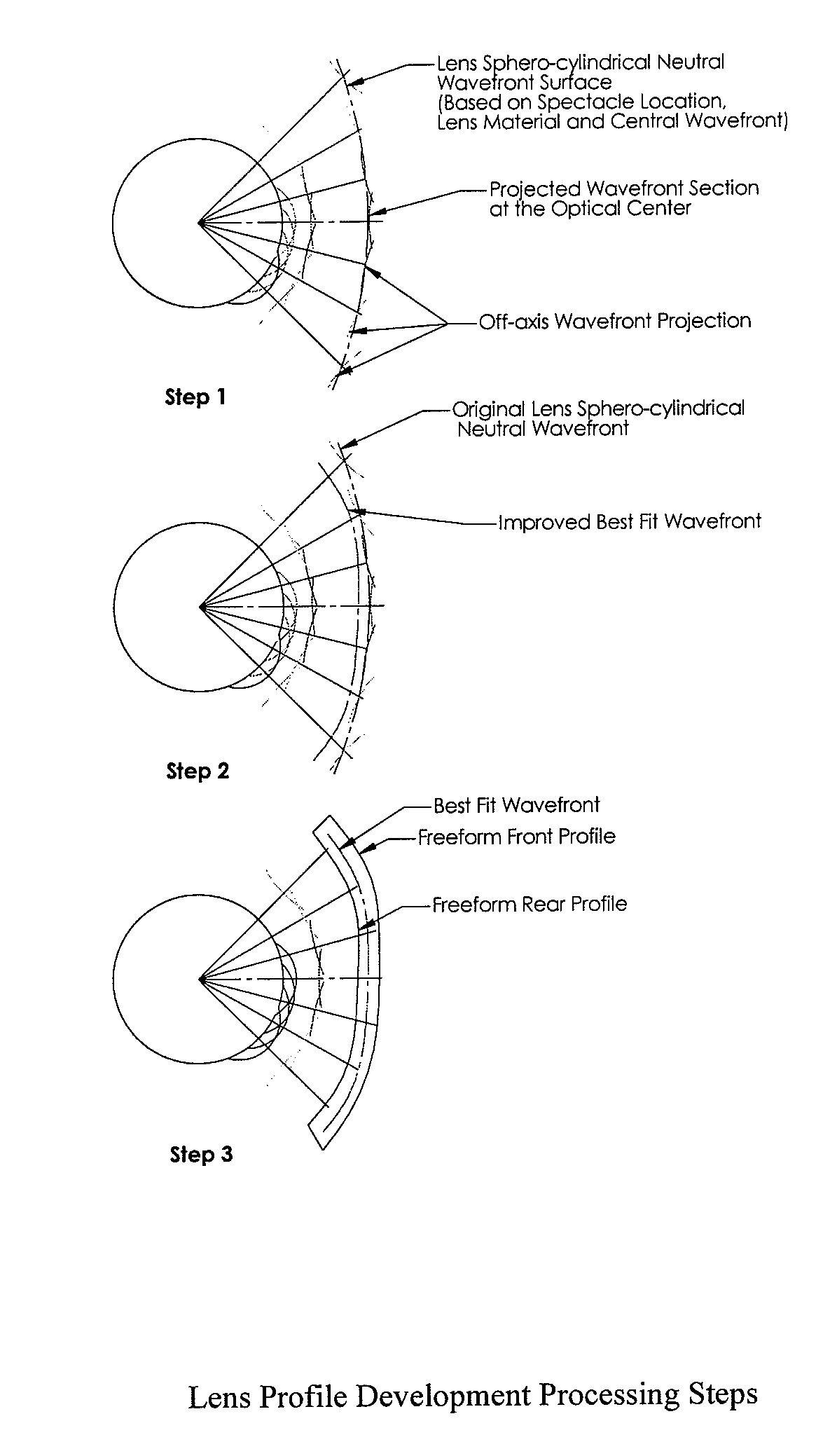

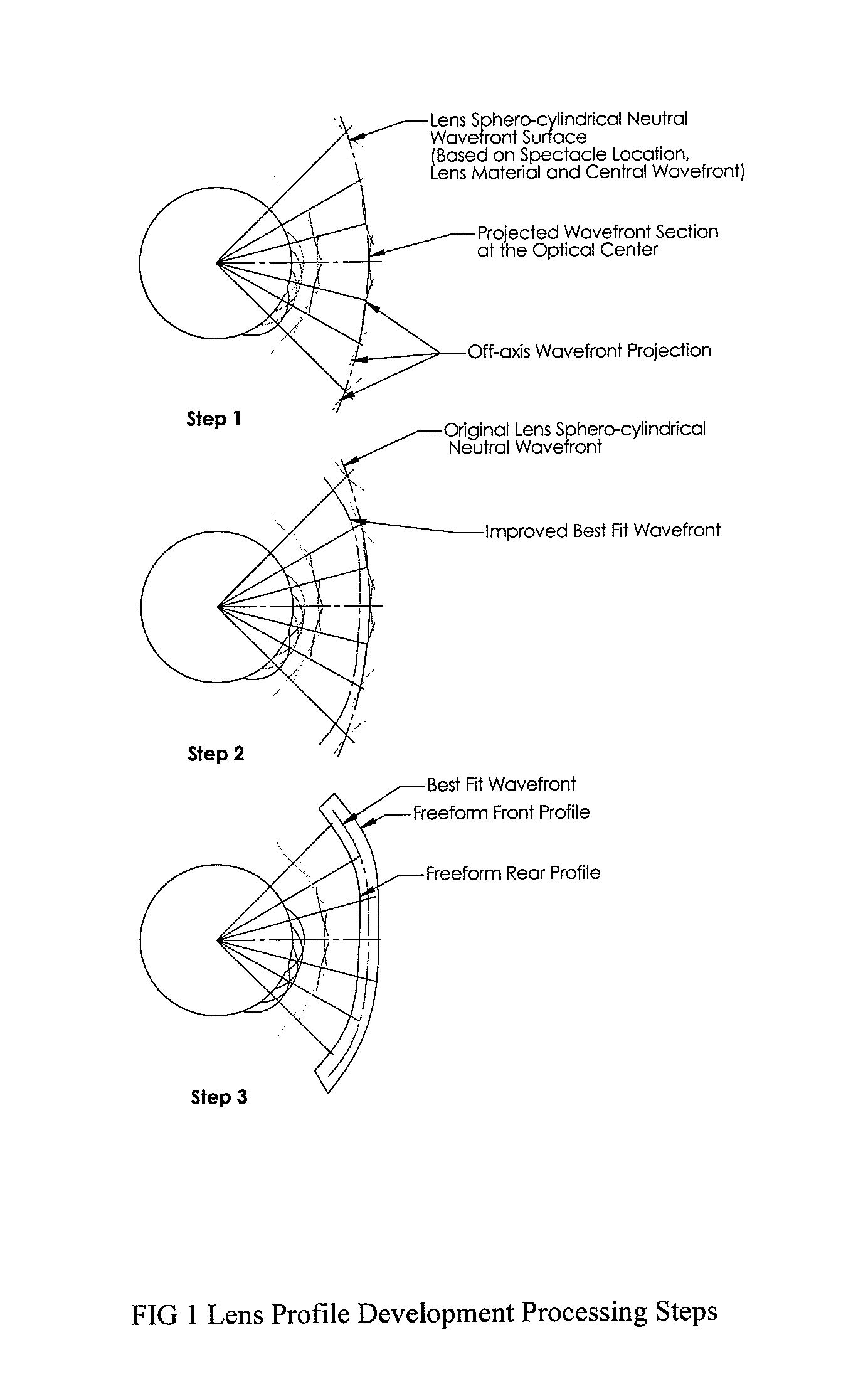

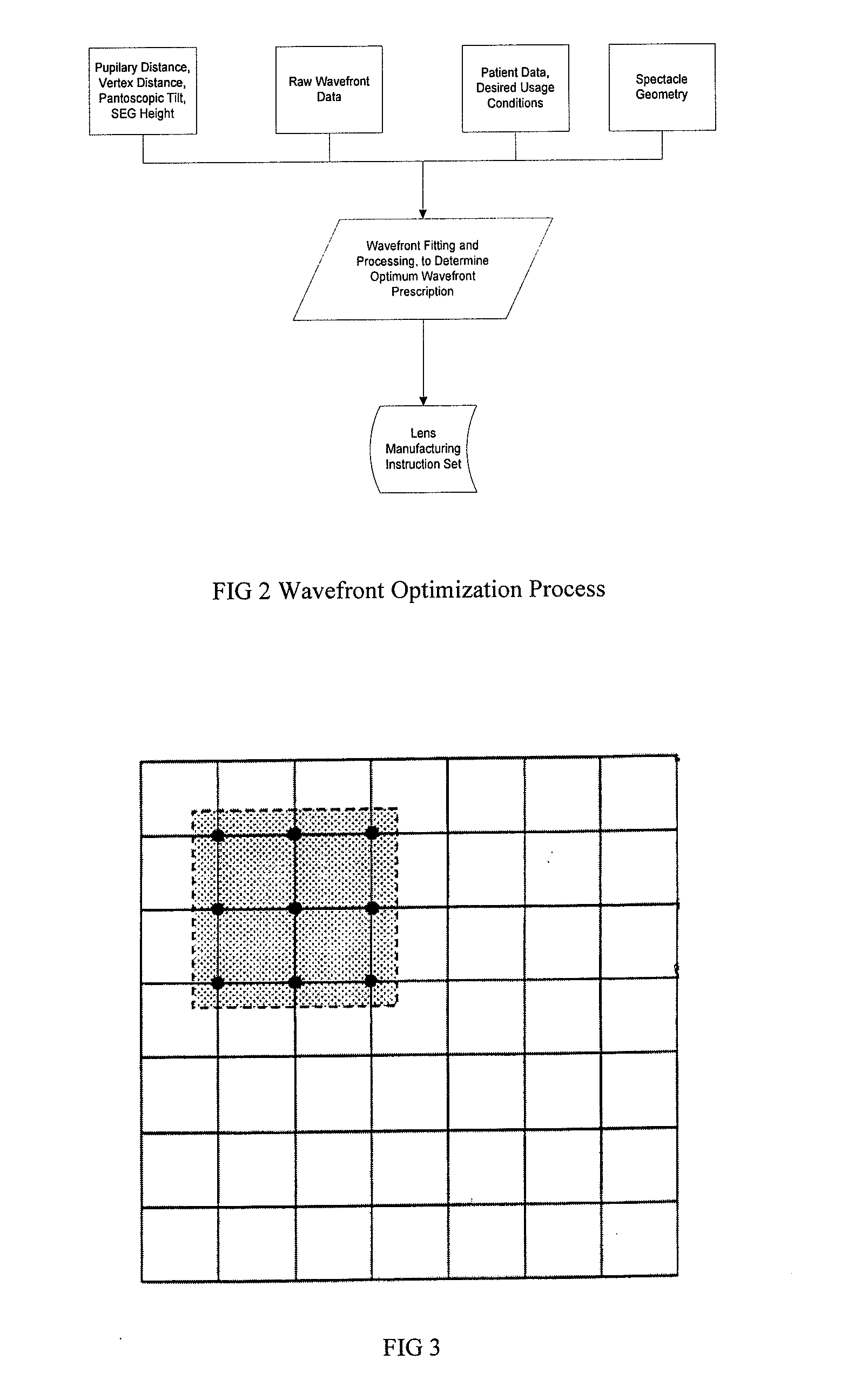

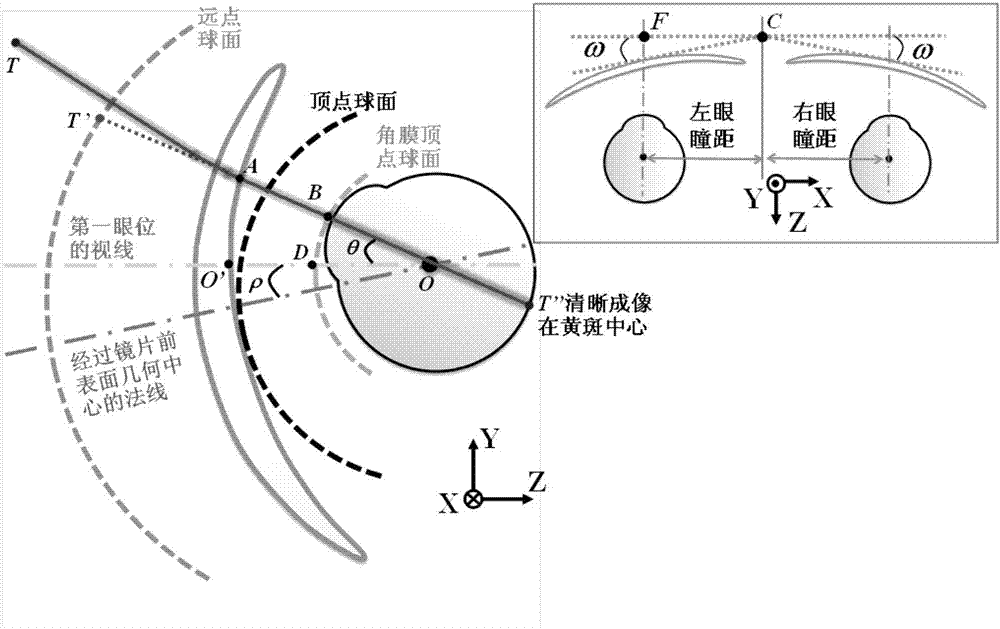

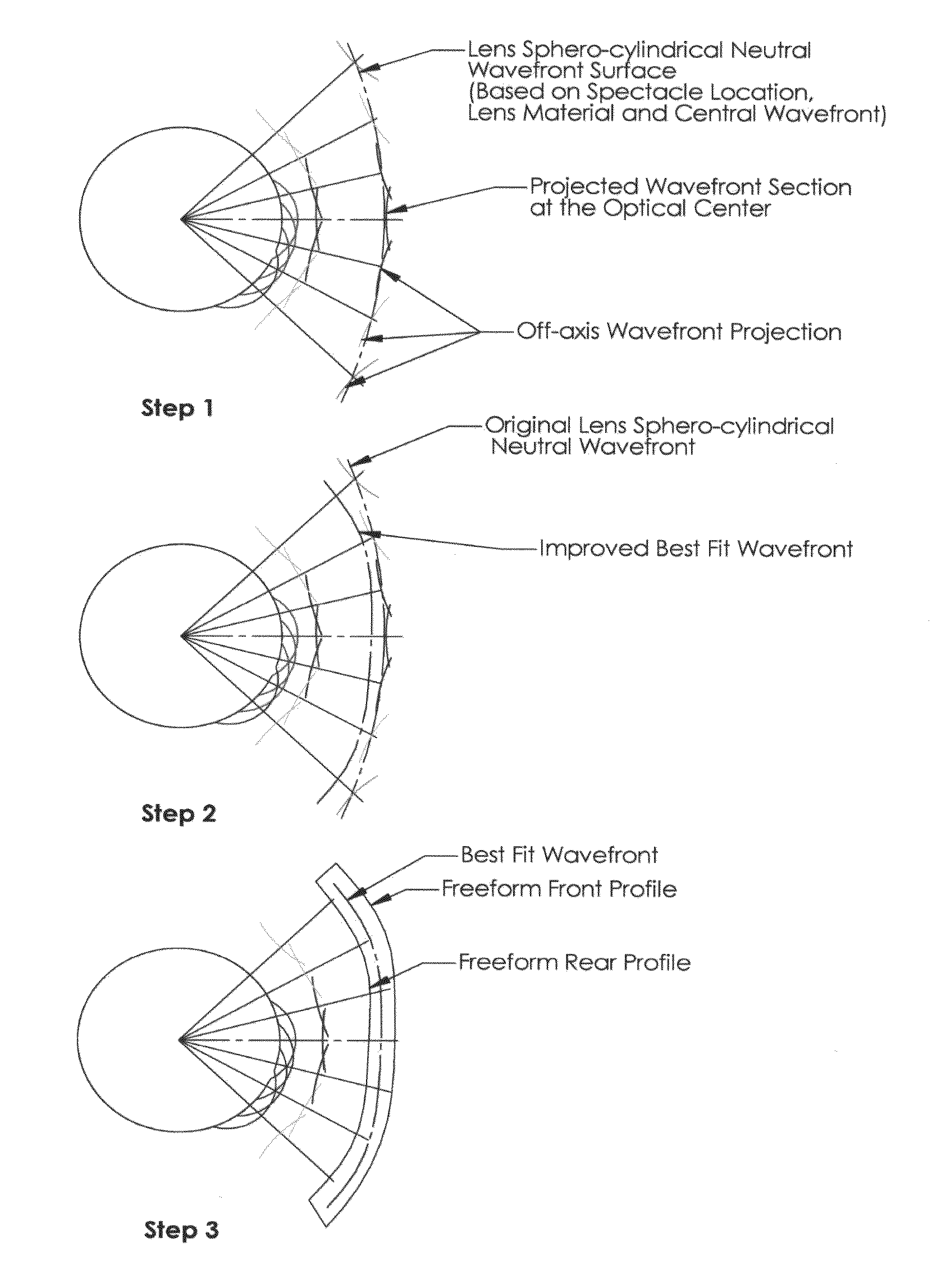

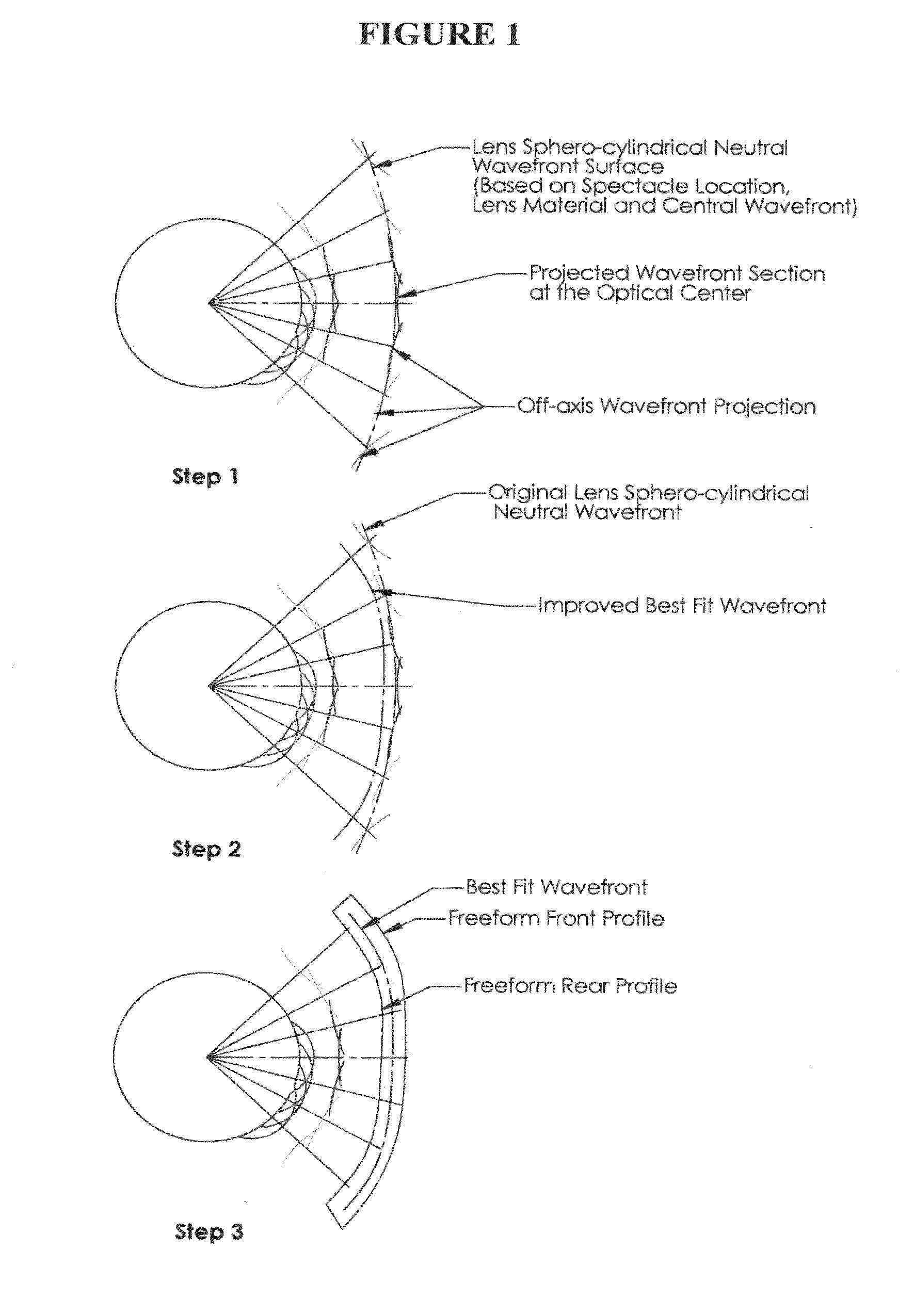

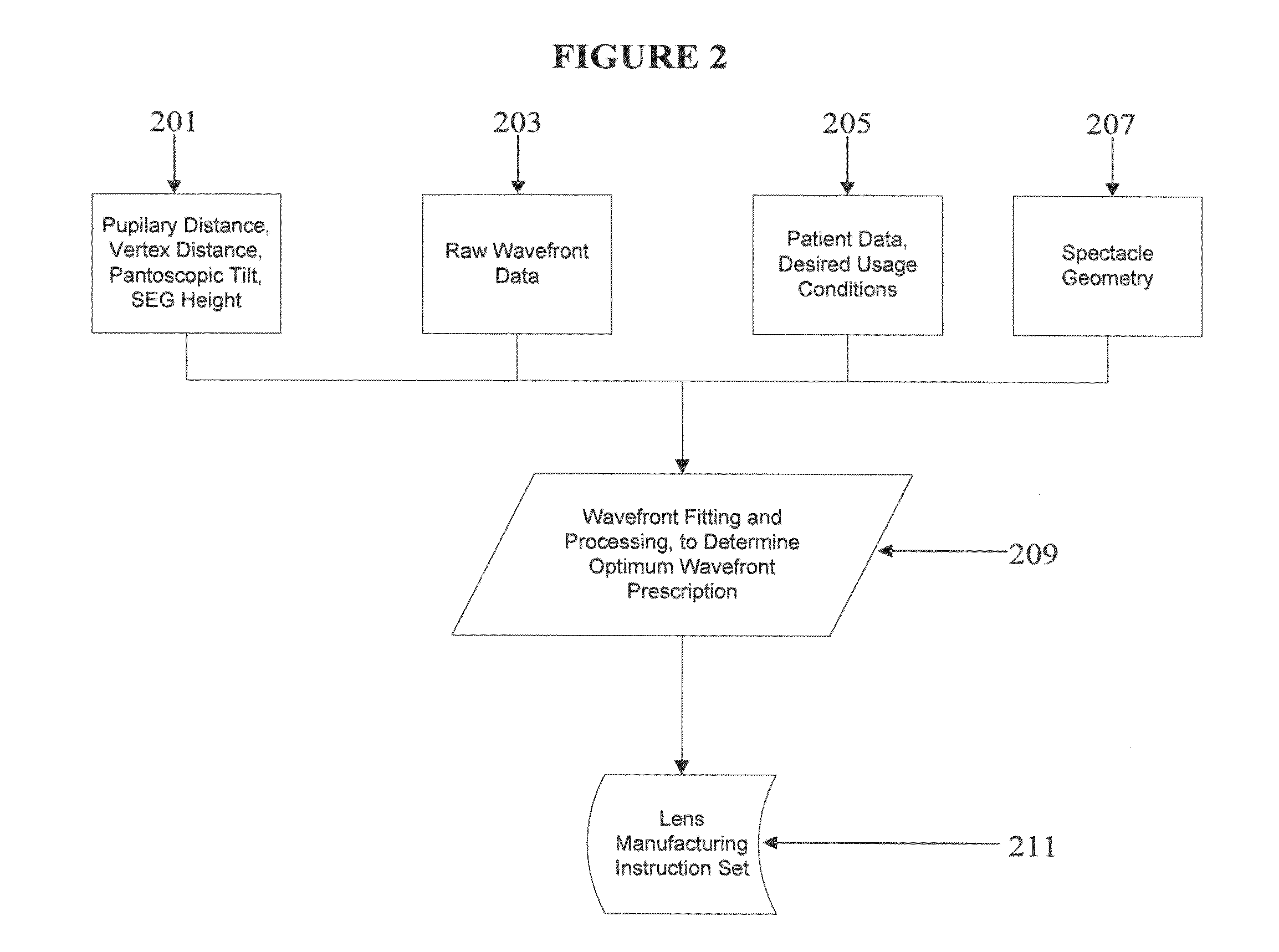

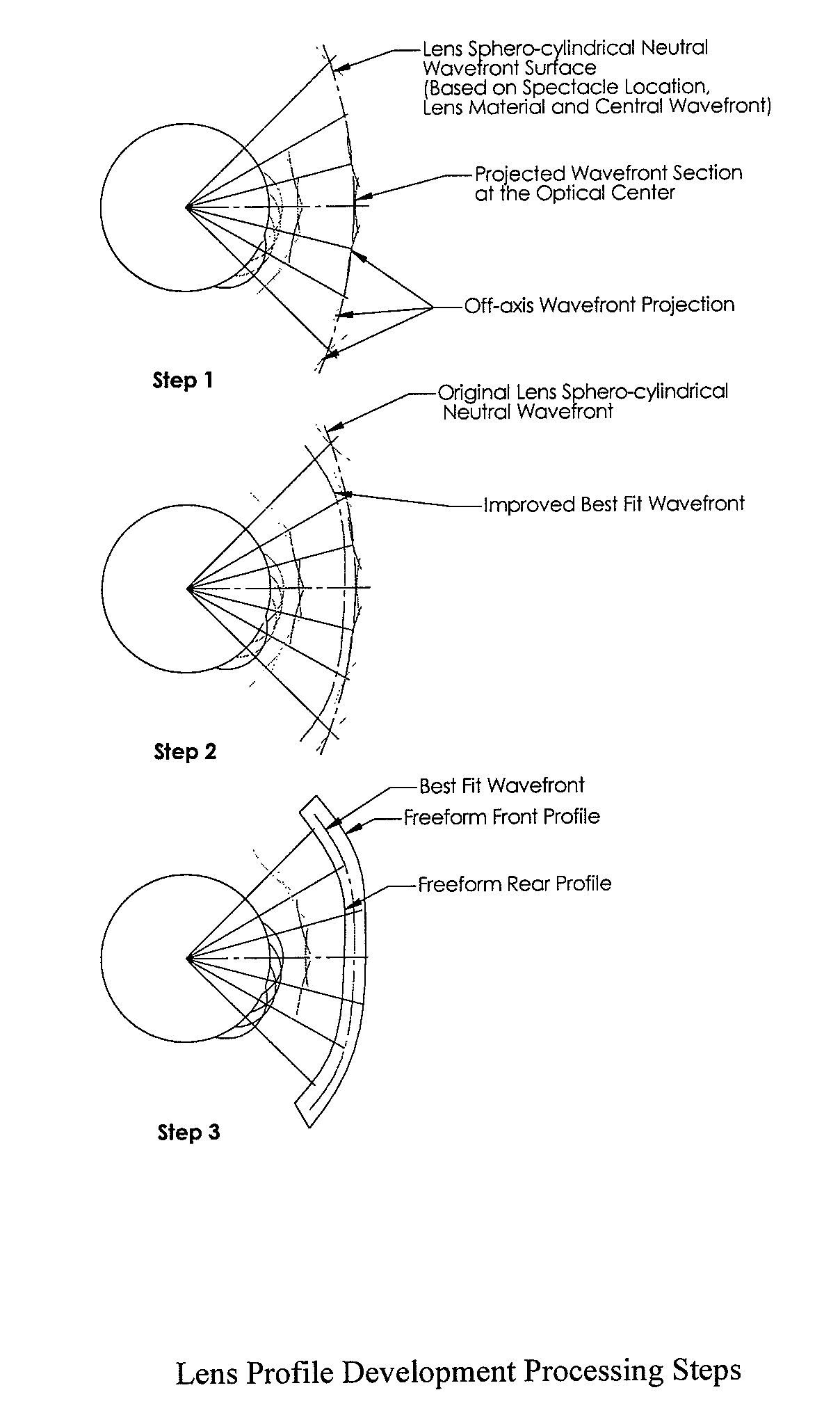

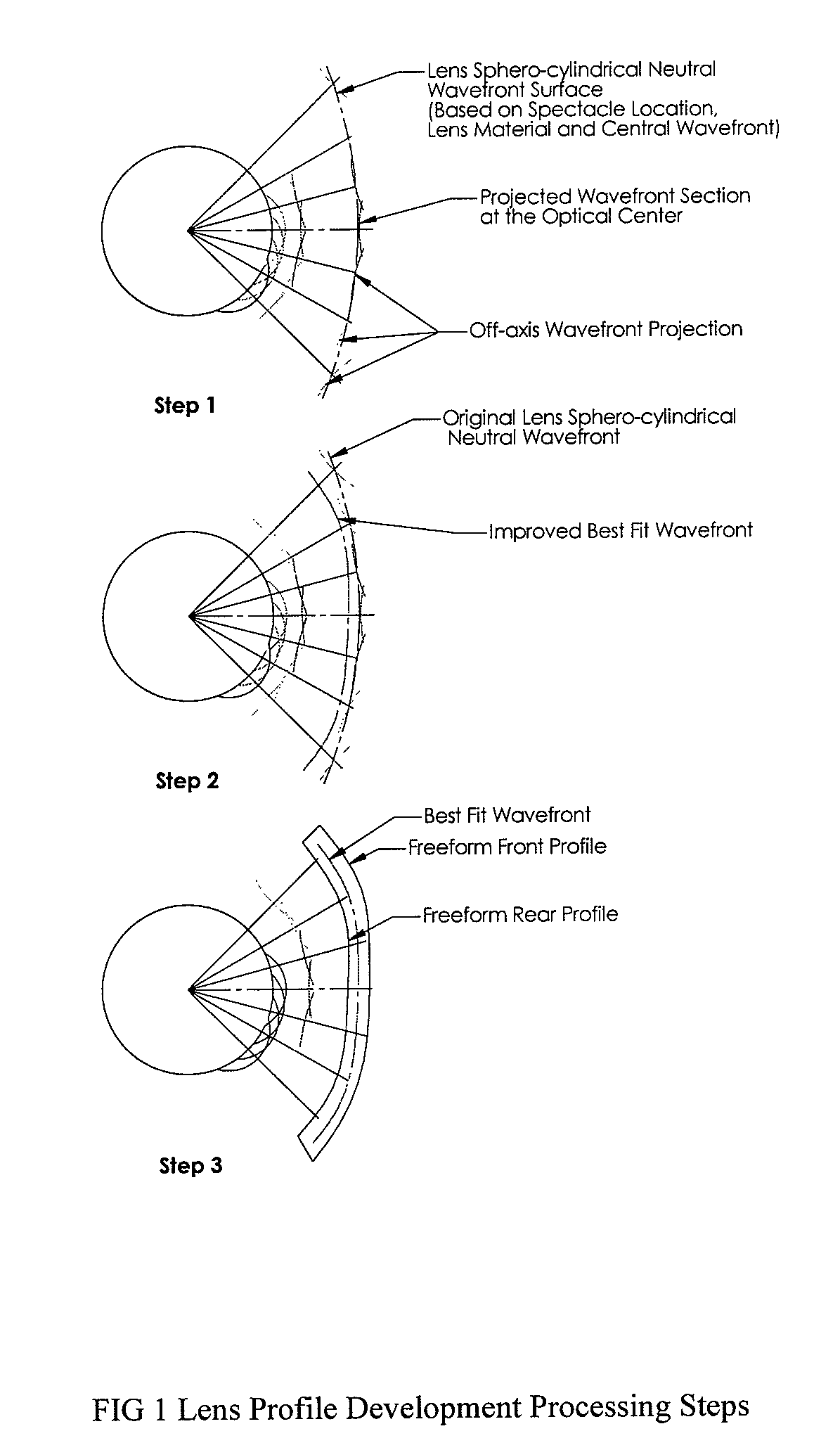

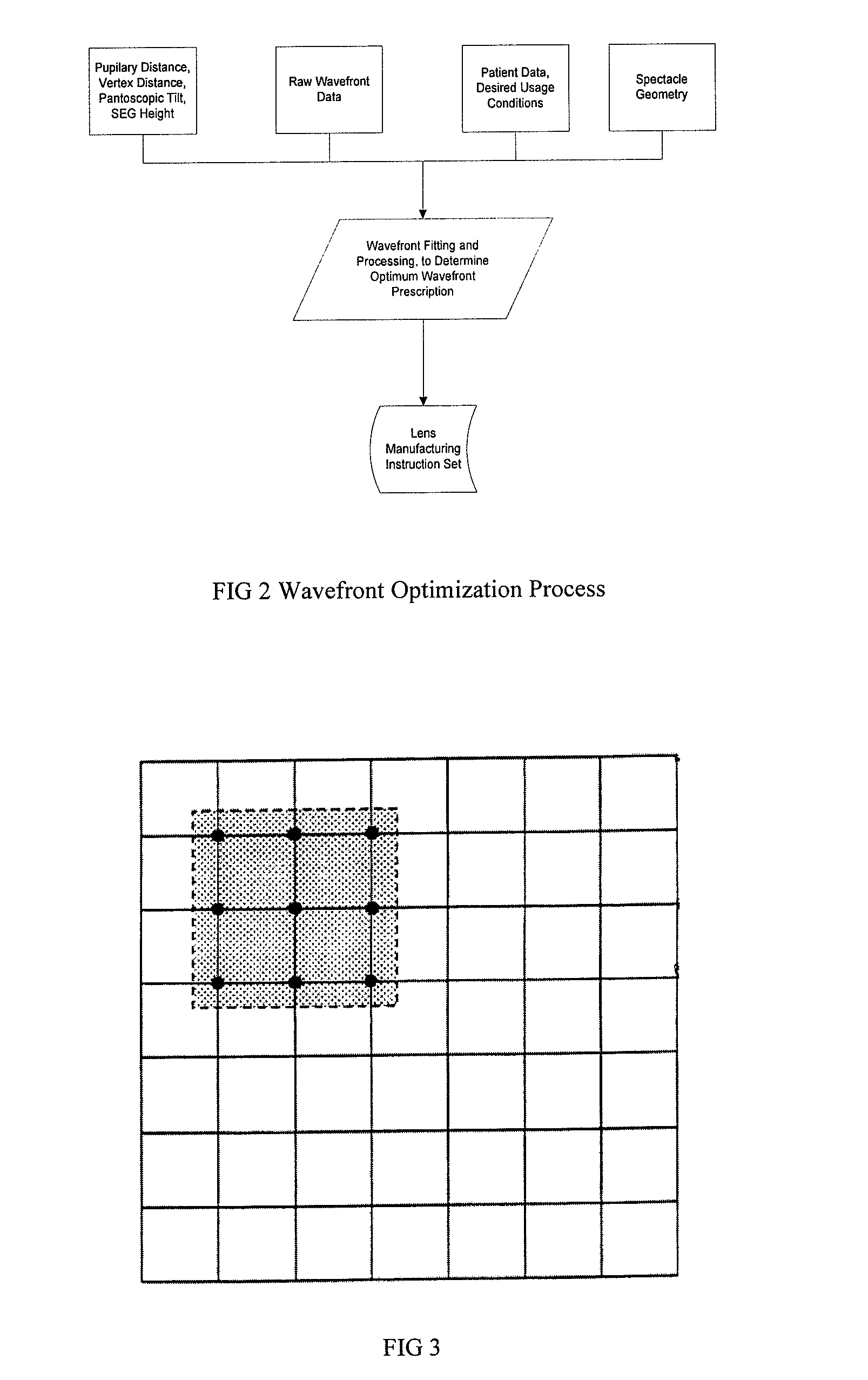

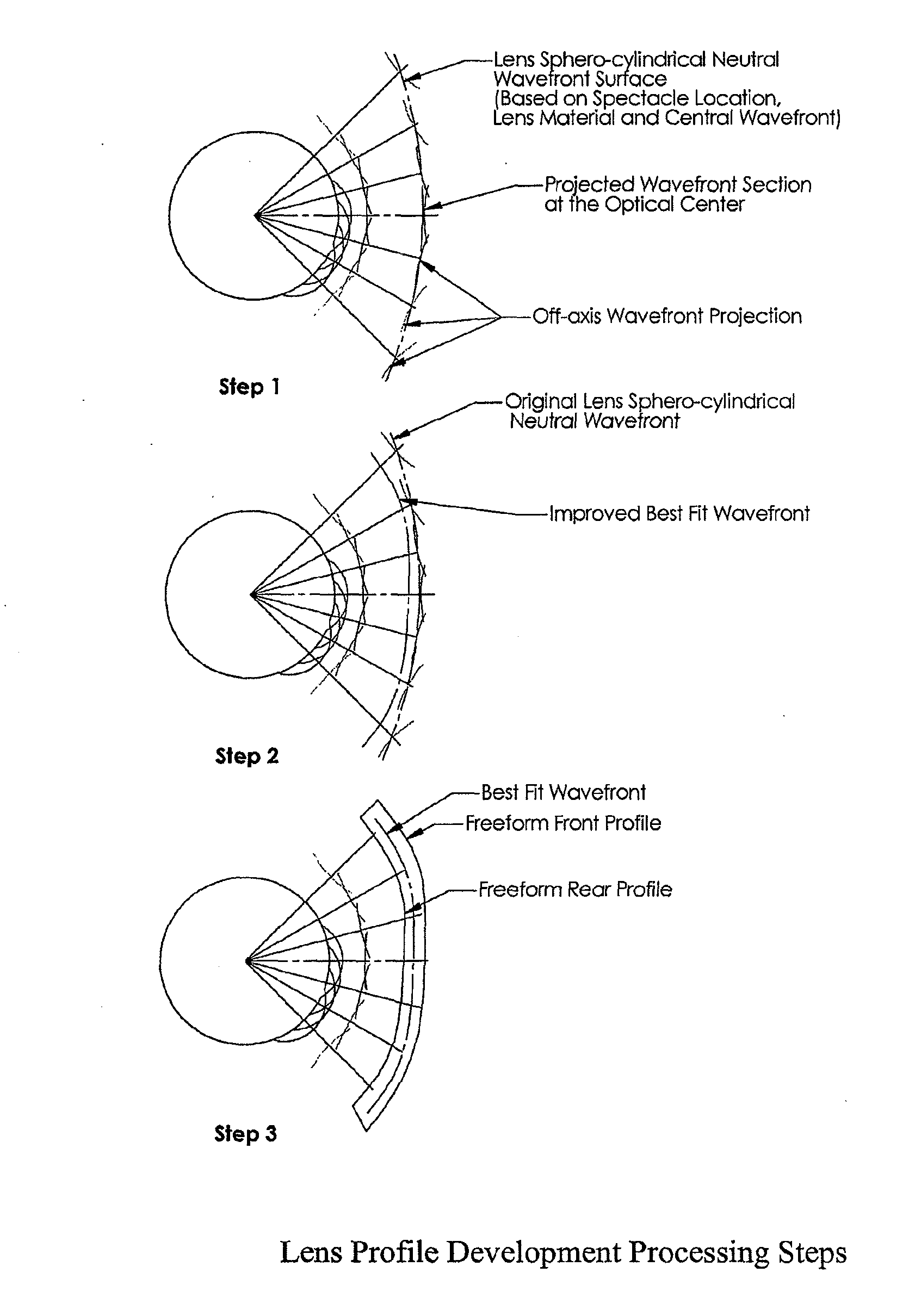

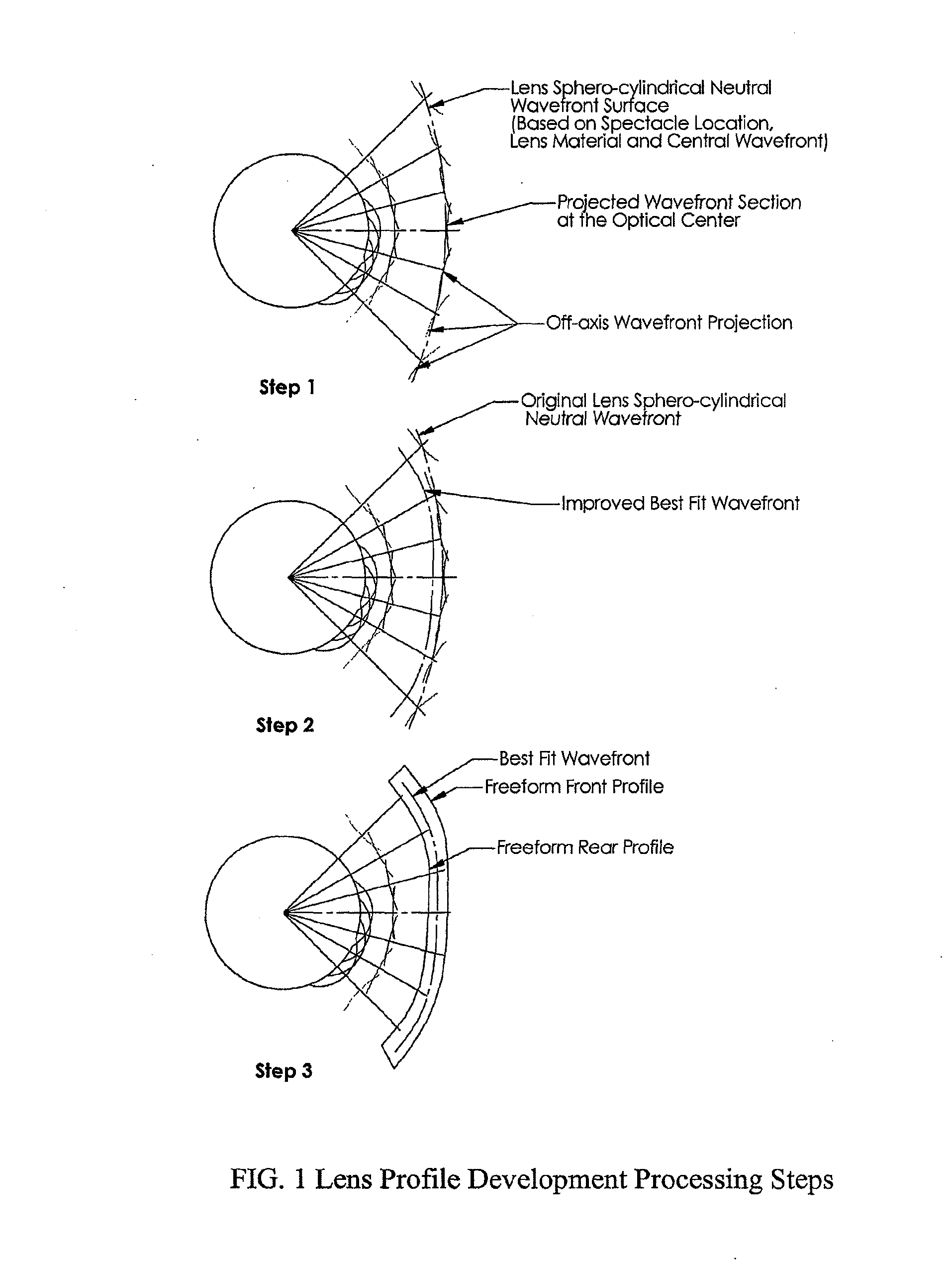

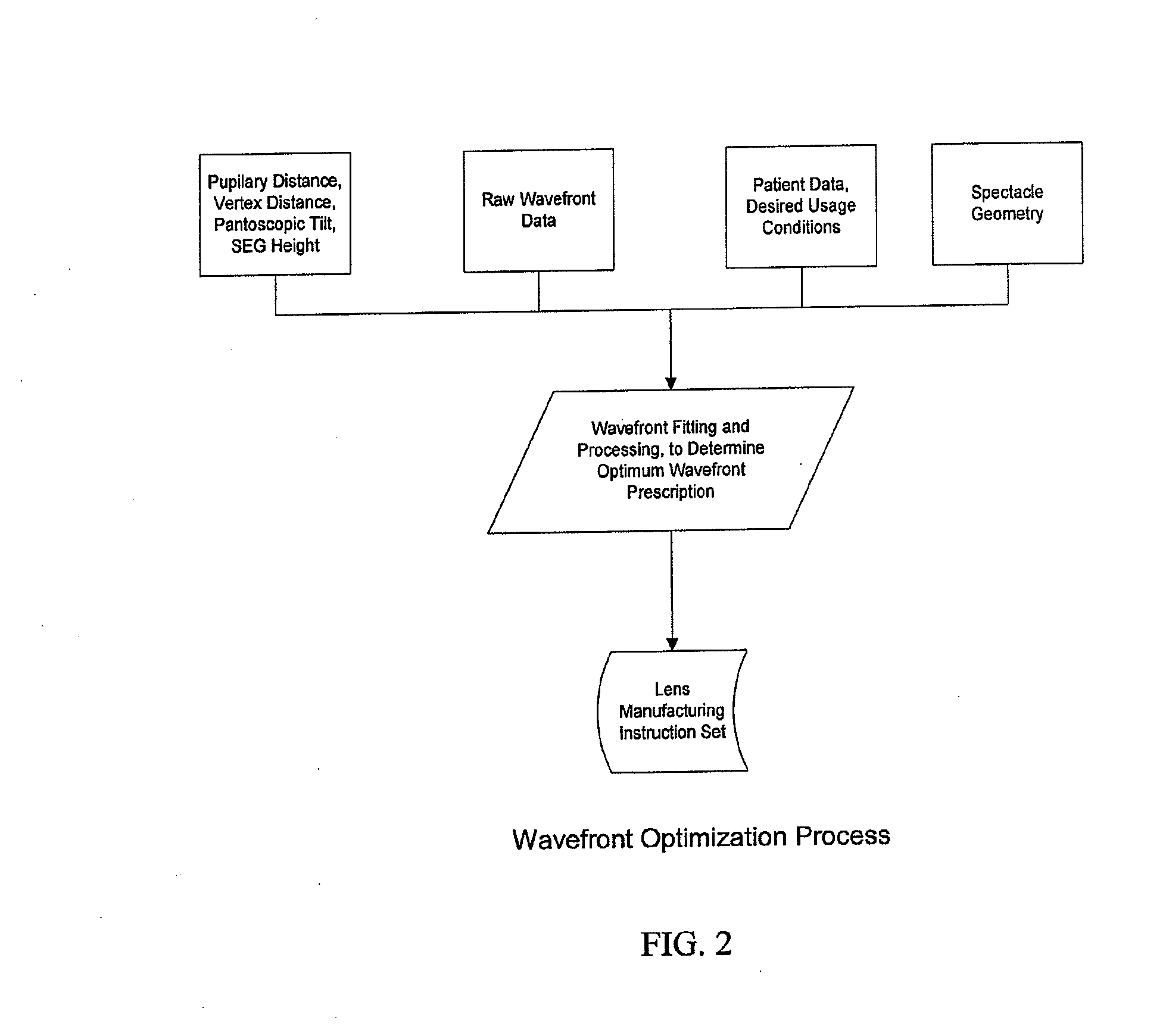

Customized Z-Lens Design Program

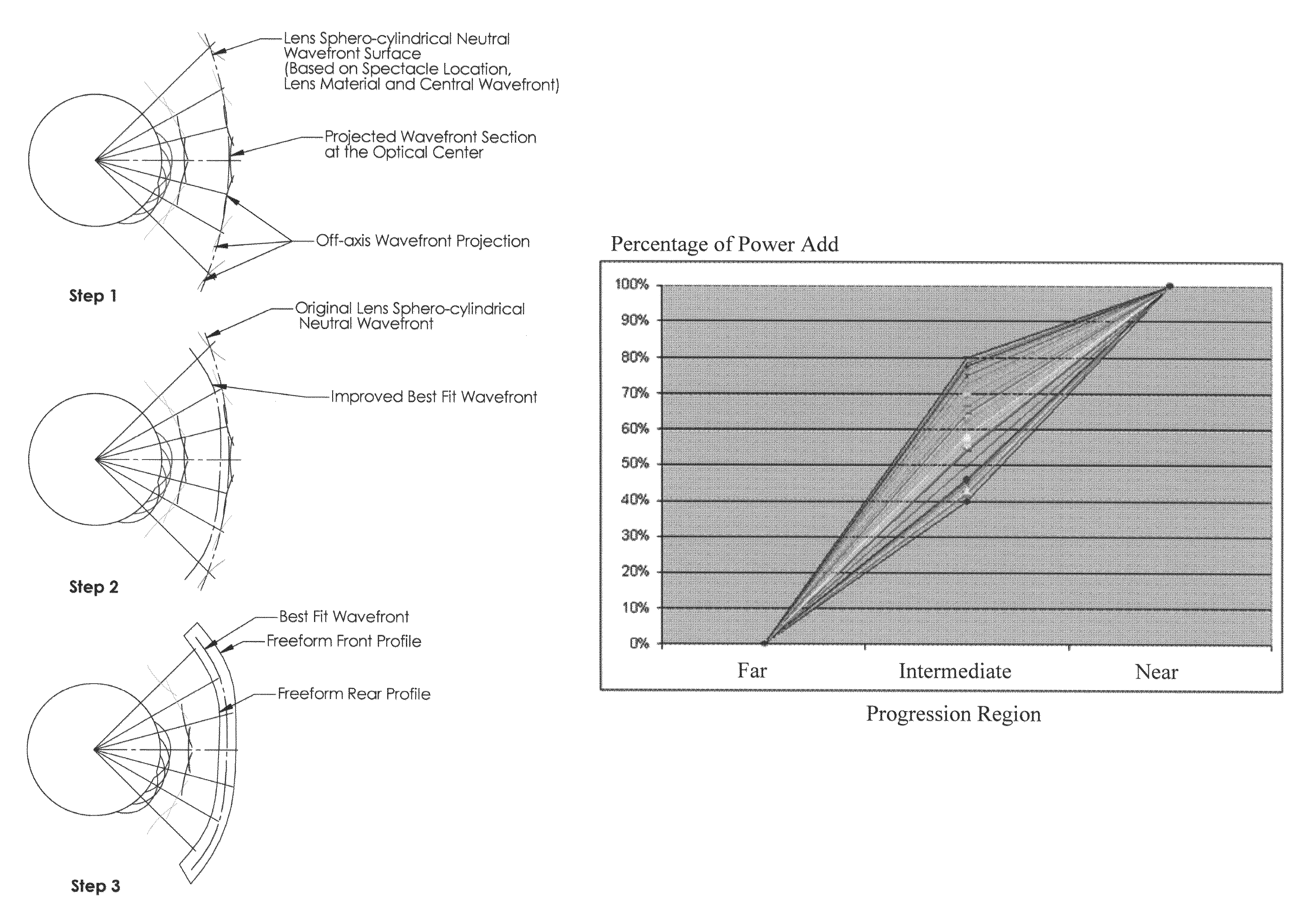

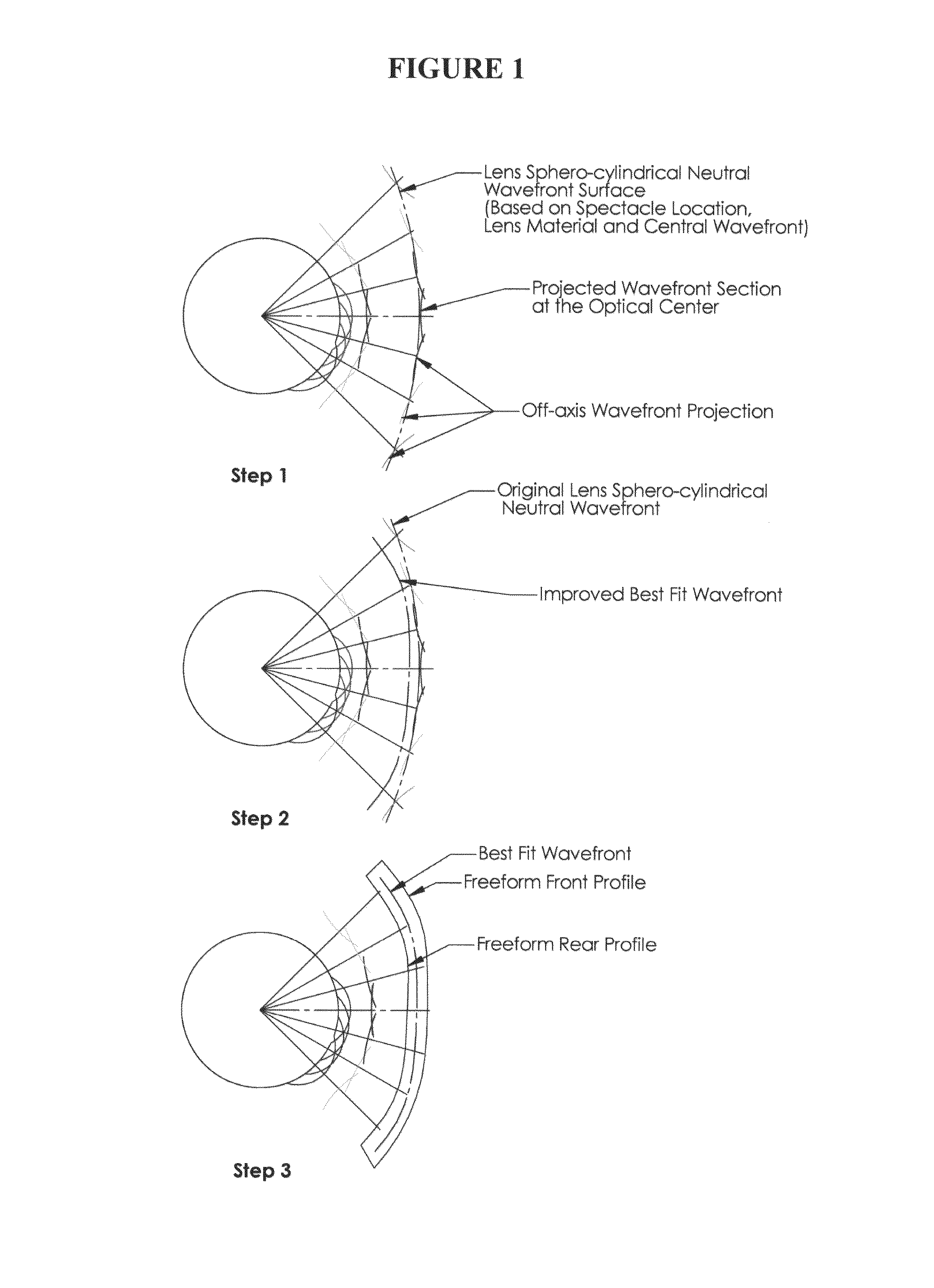

Embodiments of the invention pertain to a method for producing a spectacle lens with optimal correction across the entire lens taking into account the patient's complete measured wavefront. Specific embodiments can also take into account one or more additional factors such as vertex distance, SEG height, pantoscopic tilt, and use conditions. The lens wavefront can be achieved by optimizing a corrected wavefront, where the corrected wavefront is the combined effect of the patient's measured wavefront and the lens wavefront. The optimization of the corrected wavefront can involve representing the measured wavefront and the lens wavefront on a grid. In an embodiment, the grid can lie in a plane. During the optimization, a subset of the grid can be used for the representation of the measured wavefront at a point on the grid so as to take into account the portions of the measured wavefront that contribute to the corrected wavefront at that point on the grid.

Owner:ESSILOR INT CIE GEN DOPTIQUE

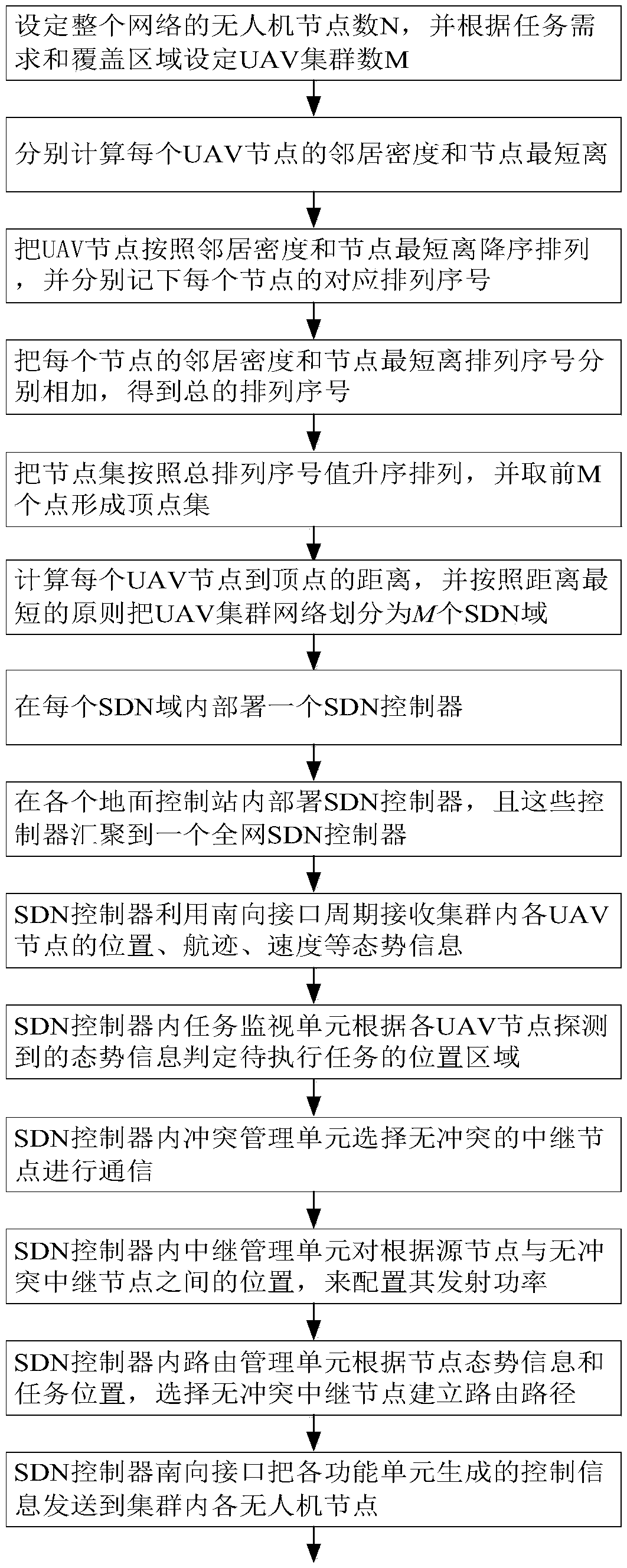

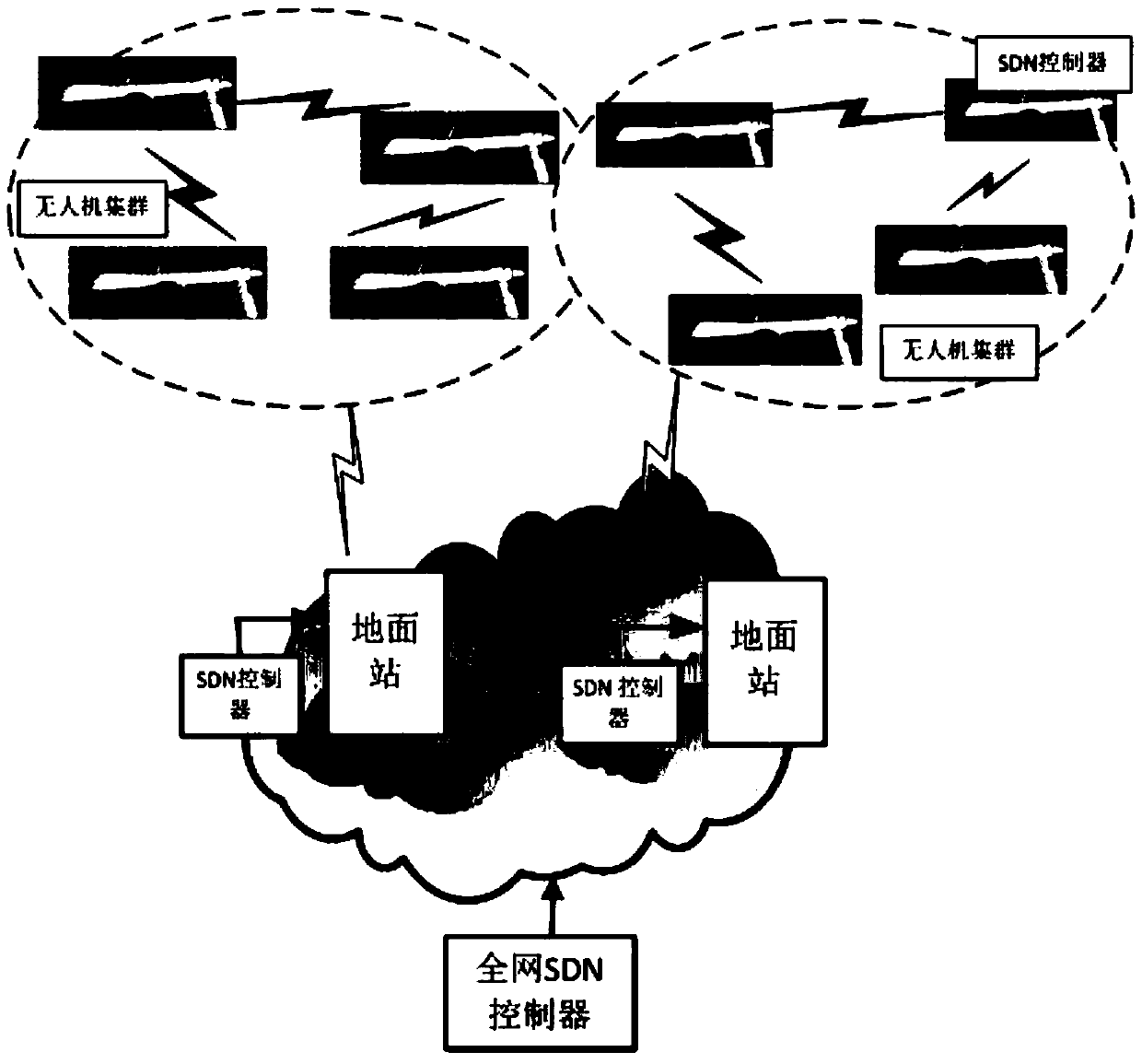

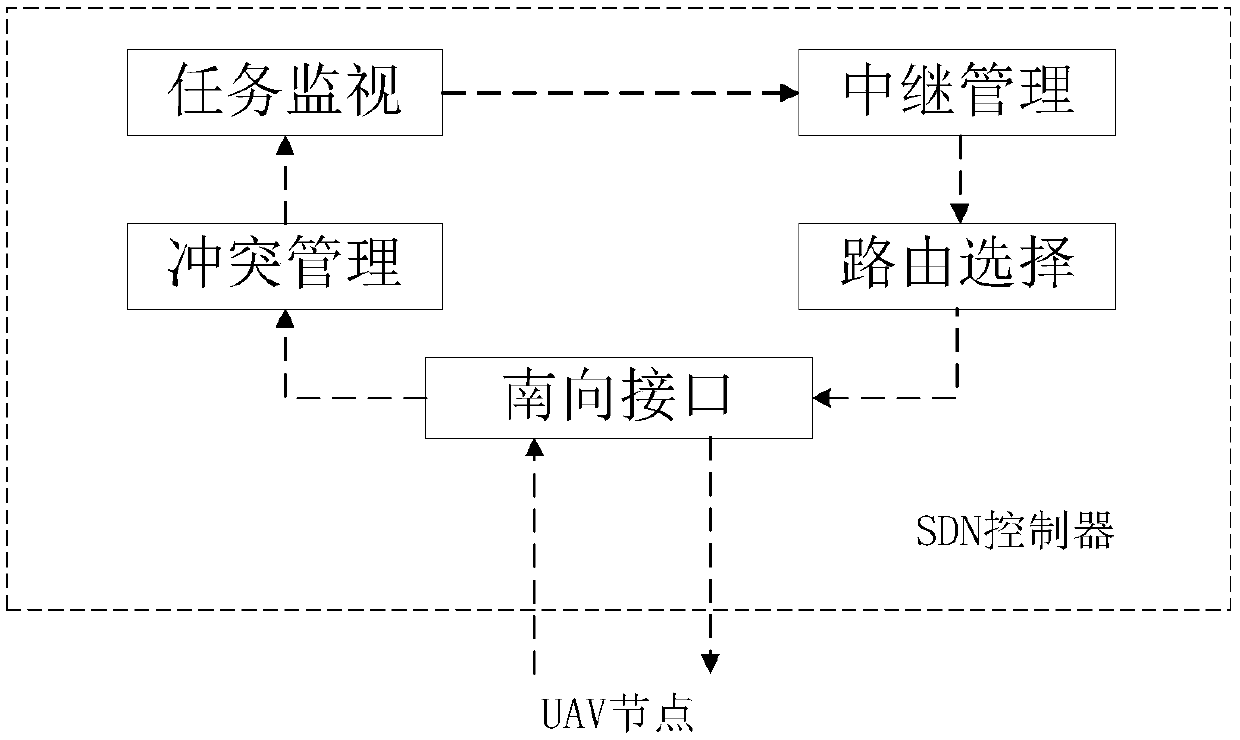

Software-defined drone cluster network controller design method

InactiveCN109525958AStable InternetReduce complexityParticular environment based servicesVehicle wireless communication serviceRound complexityNetwork control

The invention discloses a software-defined drone cluster network control method, comprising the following steps: firstly dividing the SDN control domain according to the mission requirement and coverage area of the UAV, sorting the nodes with the neighbor densities and the connection distance values respectively by calculating the neighbor density and connection distance of each node, adding the sort numbers to obtain a total sort number of the nodes, obtaining an area vertex set according to the total sort number value, dividing the network nodes into a plurality of SDN control domains according to the principle of shortest area vertex distance, then centrally controlling the cluster network at the ground control station and the SDN controller deployed in the SDN domain, and performing functions such as task monitoring, conflict management, relay management, data forwarding, and route calculation by the software-based controller, so that the deployment of the controller can be flexibly adaptive to the change of the network topology, which facilitates flexible management of local network devices, reduces UAV network device complexity and communication delay, and enables stable interconnection of UAV nodes.

Owner:BEIJING UNIV OF TECH

Method of designing progressive addition lenses

Embodiments of the invention pertain to a method for producing a spectacle lens with optimal correction across the entire lens taking into account the patient's complete measured wavefront. Specific embodiments can also take into account one or more additional factors such as vertex distance, segmental fitting height, pantoscopic tilt, and use conditions. The lens wavefront can be achieved by optimizing a corrected wavefront, where the corrected wavefront is the combined effect of the patient's measured wavefront and the lens wavefront. The optimization of the corrected wavefront can involve representing the measured wavefront and the lens wavefront on a grid. In an embodiment, the grid can lie in a plane. During the optimization, a subset of the grid can be used for the representation of the measured wavefront at a point on the grid so as to take into account the portions of the measured wavefront that contribute to the corrected wavefront at that point on the grid.

Owner:ESSILOR INT CIE GEN DOPTIQUE

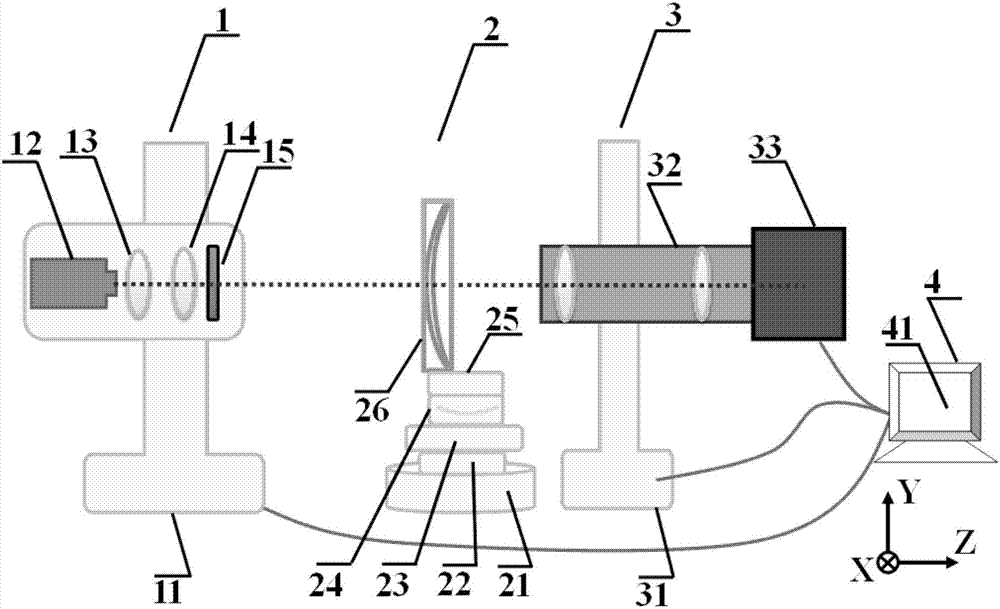

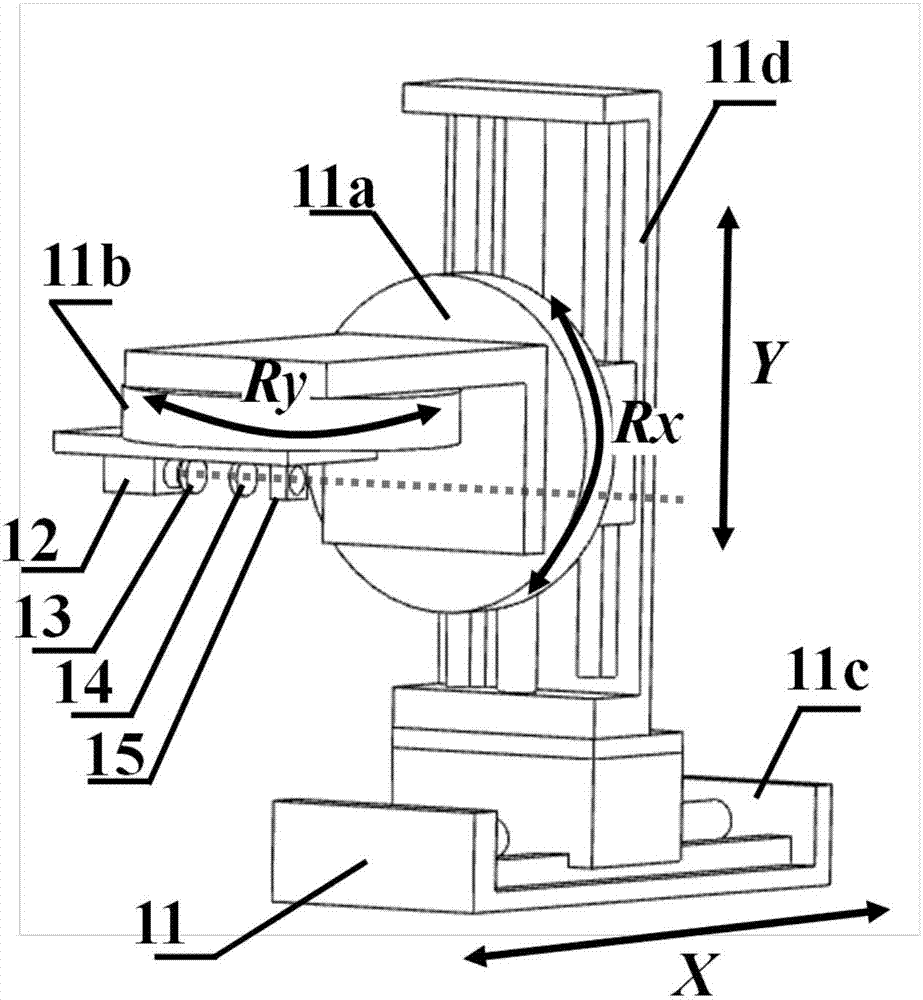

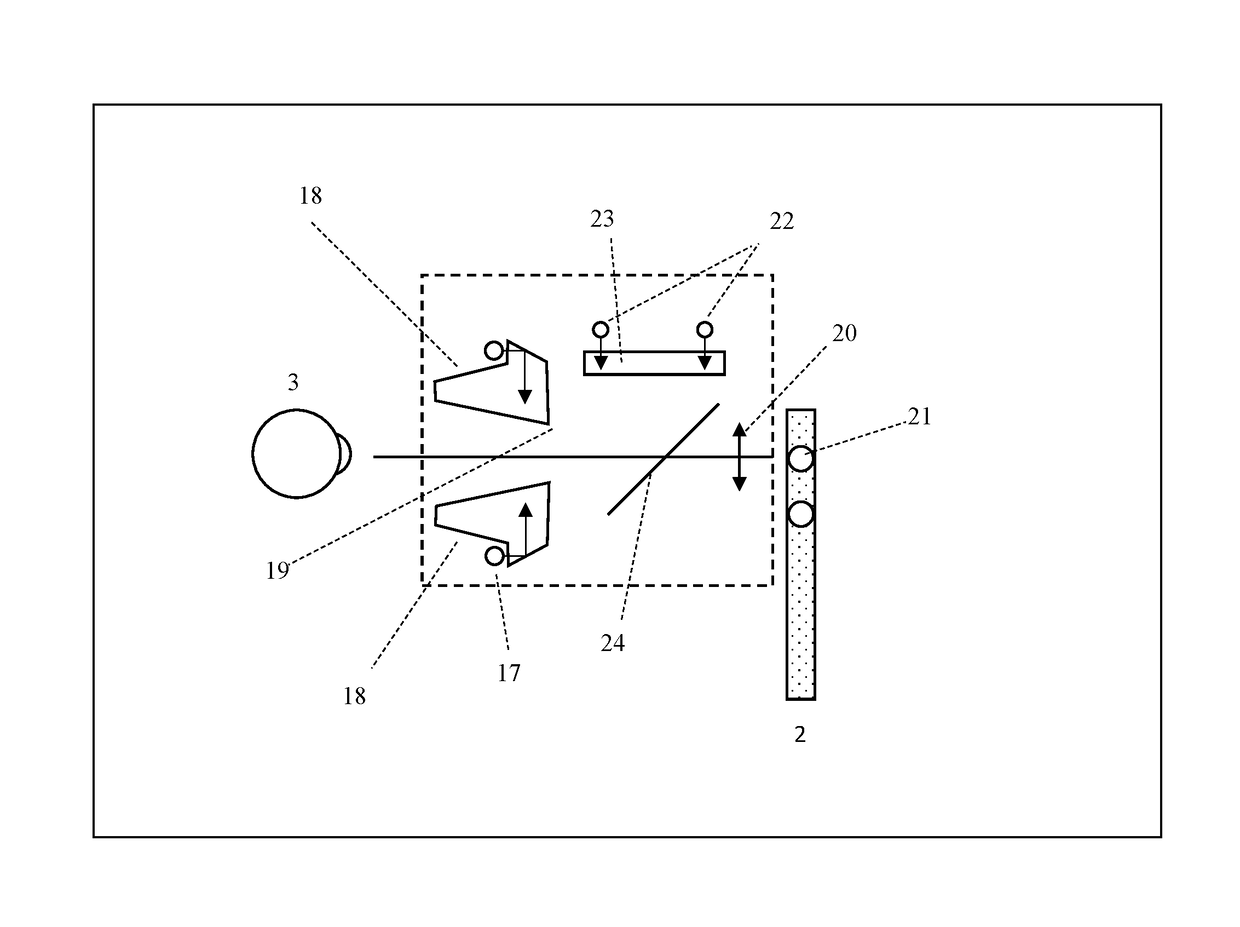

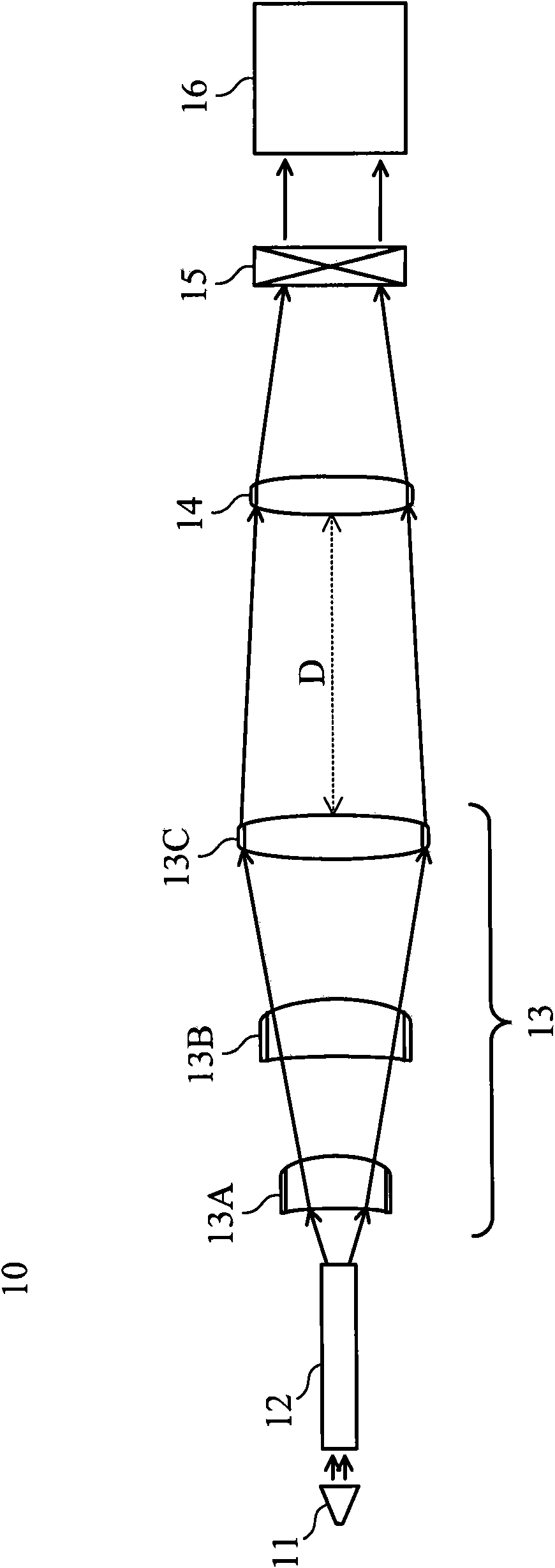

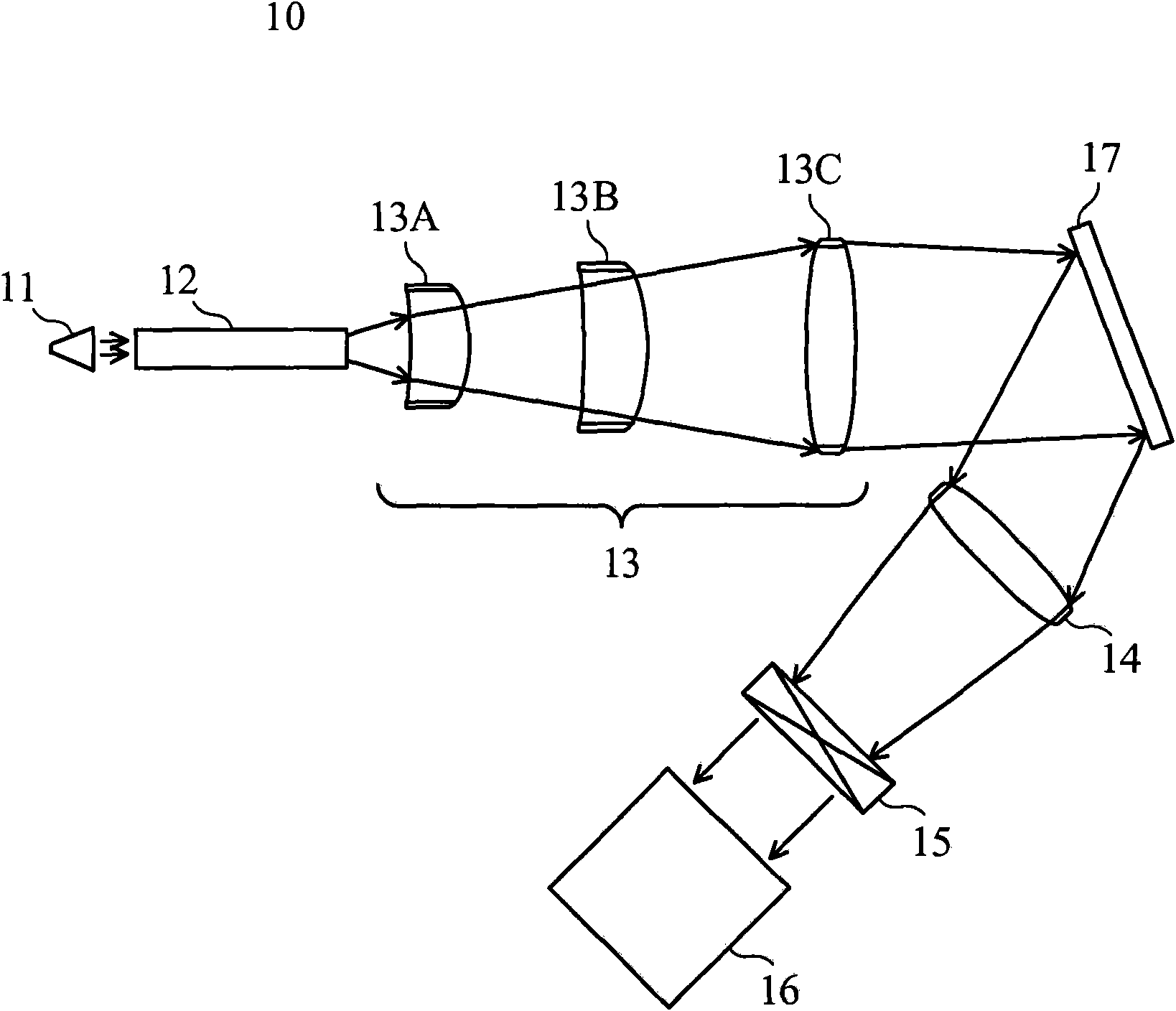

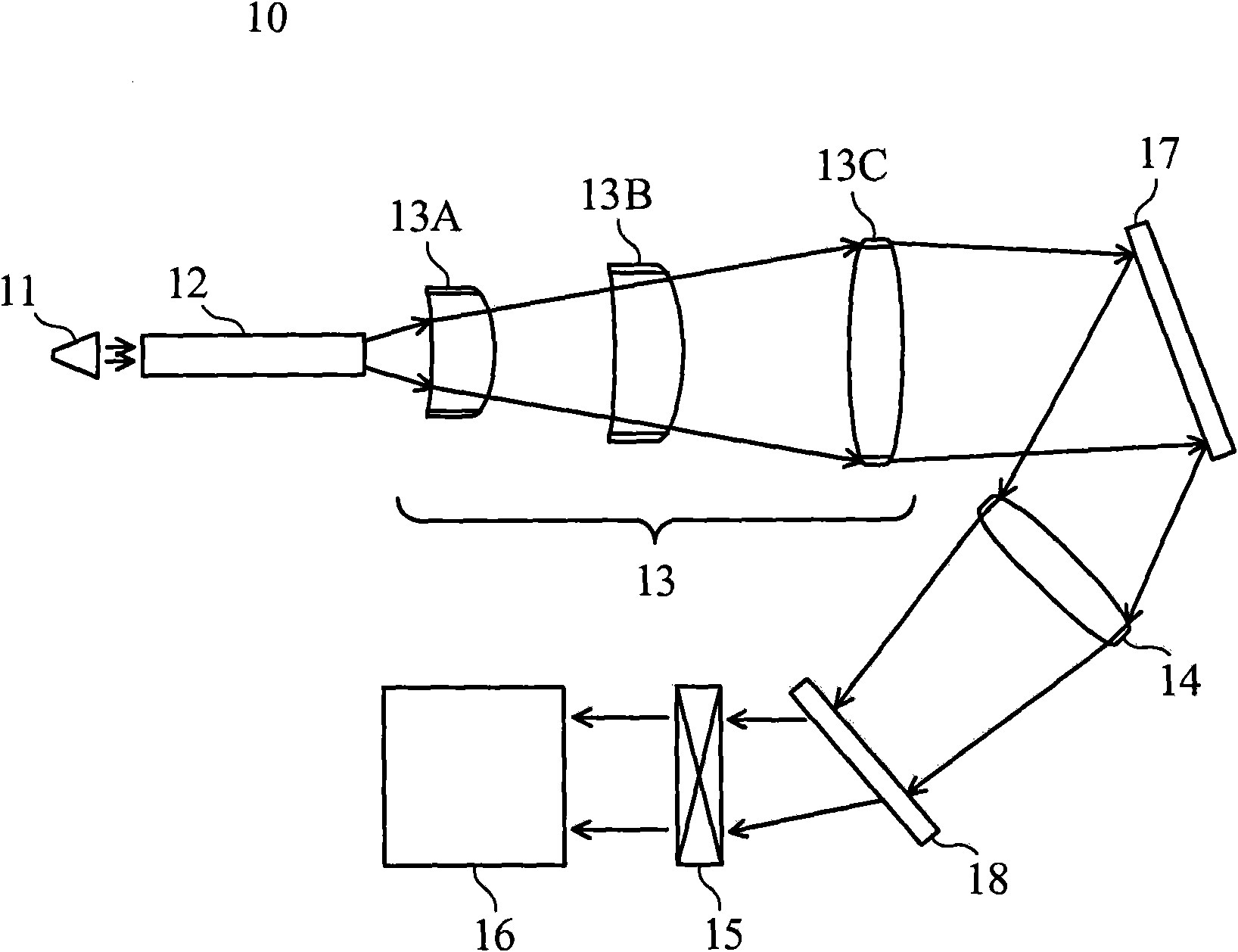

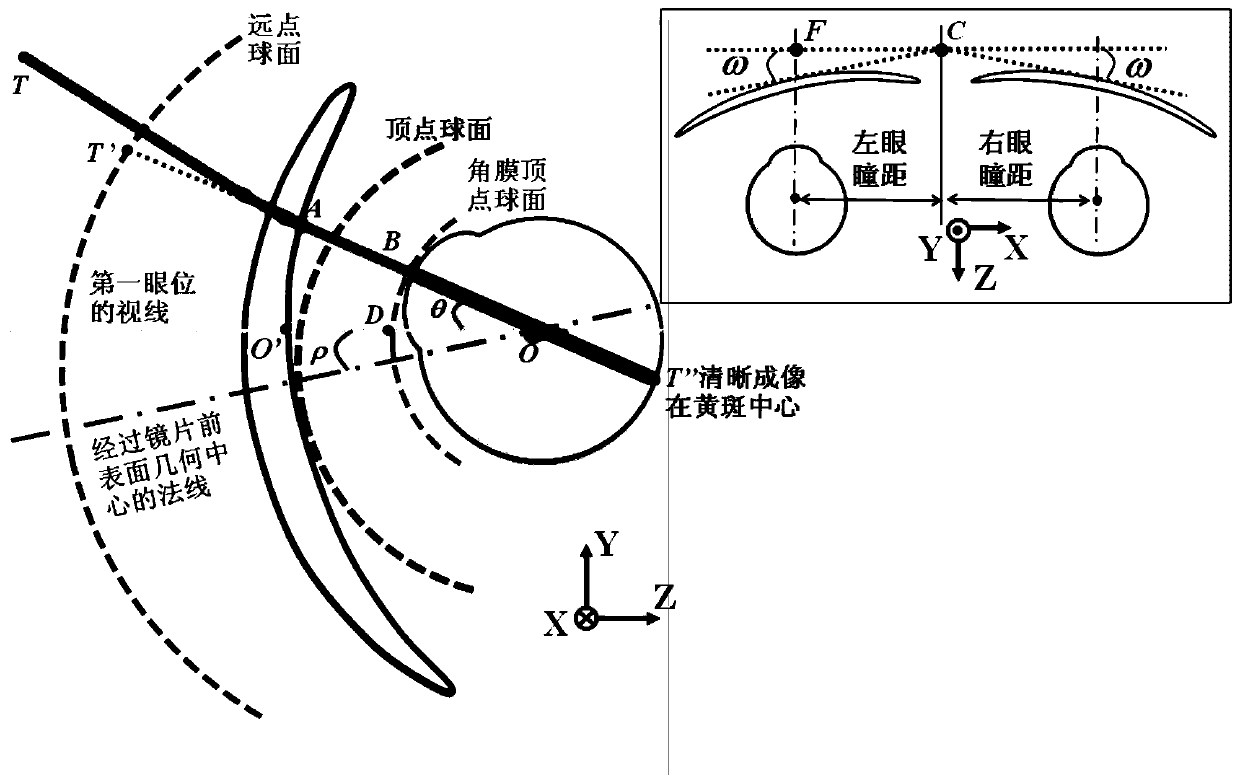

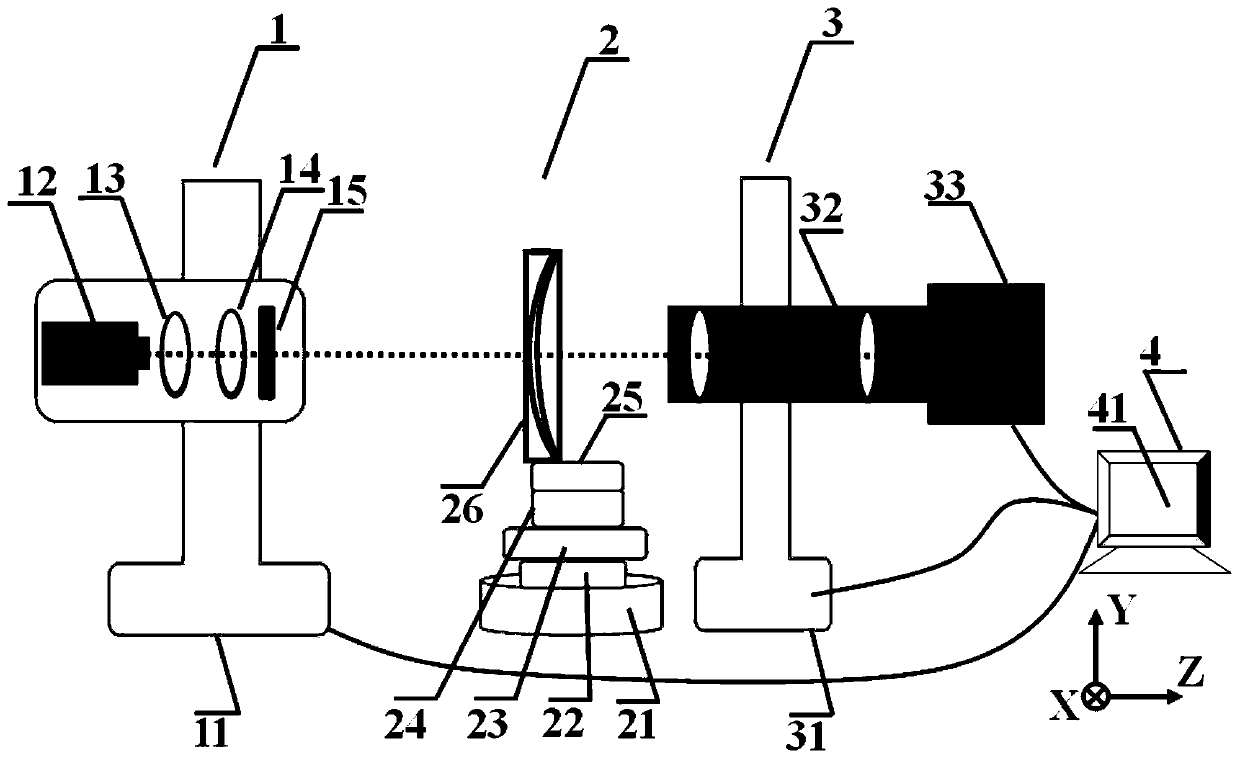

Method and device for detecting spectacle lenses based on wavefront analysis

InactiveCN107577065AEfficient measurementRealize detectionSpectales/gogglesTesting optical propertiesImaging qualityLens plate

The invention discloses a method for detecting spectacle lenses based on wavefront analysis. The method comprises a light source adjustment unit, a lens posture adjustment unit, a detection unit and asoftware module, wherein the light source adjustment unit is used to translate and rotate incident light; the lens posture adjustment unit is used to adjust initial vertex distances of lenses, a wearing view angle and facial radians of rings according to wearing parameters of a prescription for spectacles; the detection unit is used to detect an effective wavefront aberration of the lenses; the software module is used to set motion parameters of a motion platform and set detection parameters of a wavefront aberration sensor in the detection unit, and is used to receive, calculate and displayeffective wavefront aberration data of the detection unit. The method measures the effective wavefront aberration in high precision in a lens wearing state, and provides quantitative reference for designing and processing of the lenses and evaluation of optical properties and imaging quality.

Owner:TIANJIN UNIV

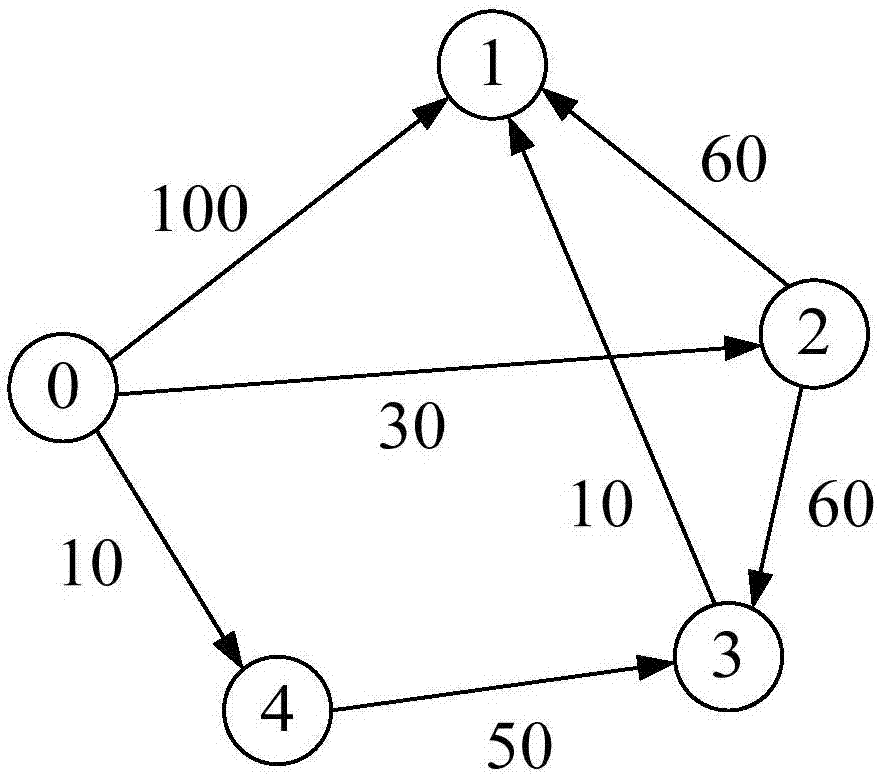

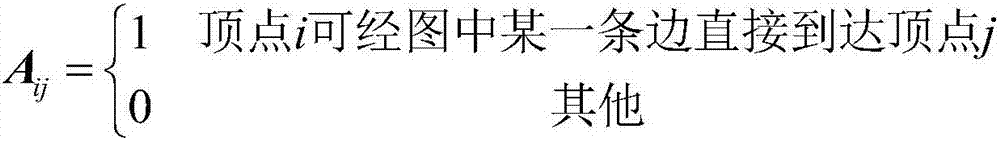

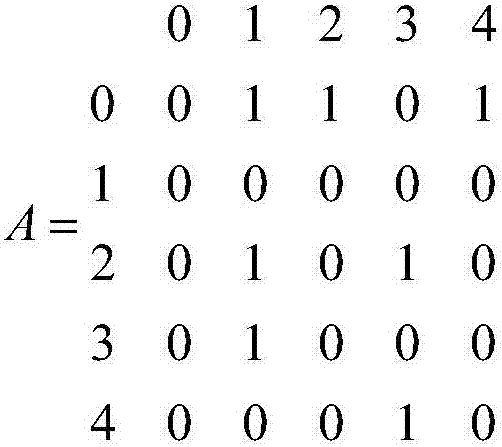

Method for searching for shortest path between two points in improved Dijkstra algorithm

ActiveCN107276896ASmall amount of calculationData switching networksShortest path searchShortest distance

The present invention provides a method for searching for the shortest path between two points in the improved Dijkstra algorithm, comprising the following steps: 1) introducing an adjacency matrix in the graph theory and assisting the search process by using an adjacency matrix, that is, after determining the shortest distance from one vertex to the starting vertex each time, finding a column wherein the row element is 1 corresponding to the vertex in the adjacency matrix; and 2) calculating and analyzing only the vertex distance value corresponding to the column with the element 1 in step 1), and effectively reducing the calculation amount of the search process. The method for path analysis based on the adjacency matrix avoids useless calculation processes of disjoint nodes, effectively reduces the amount of computation, and ensures the shortest search path.

Owner:BEIJING JIAOTONG UNIV

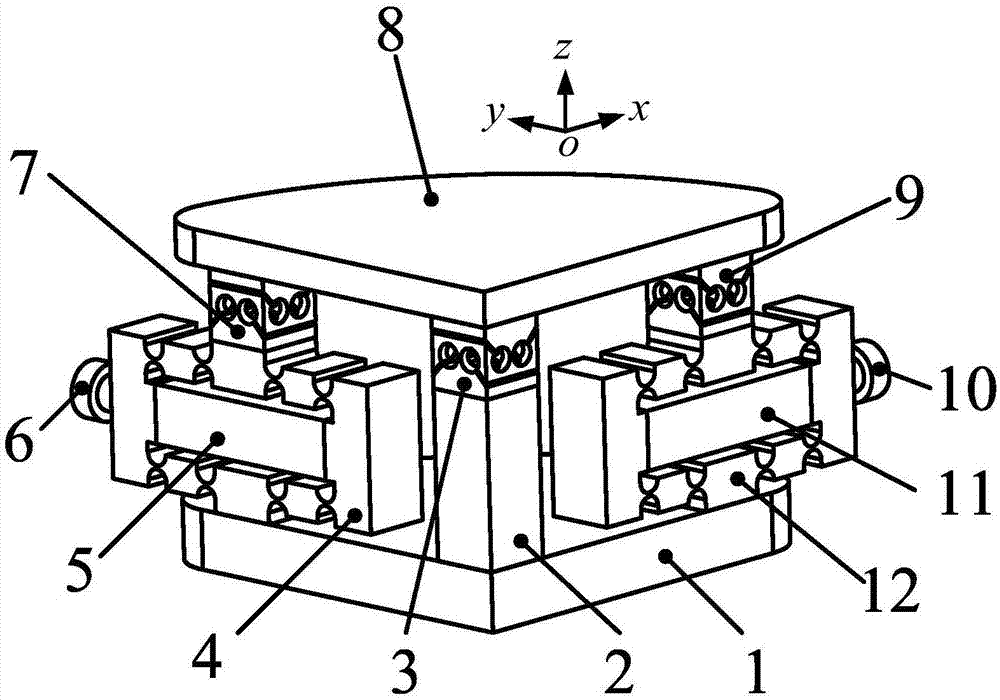

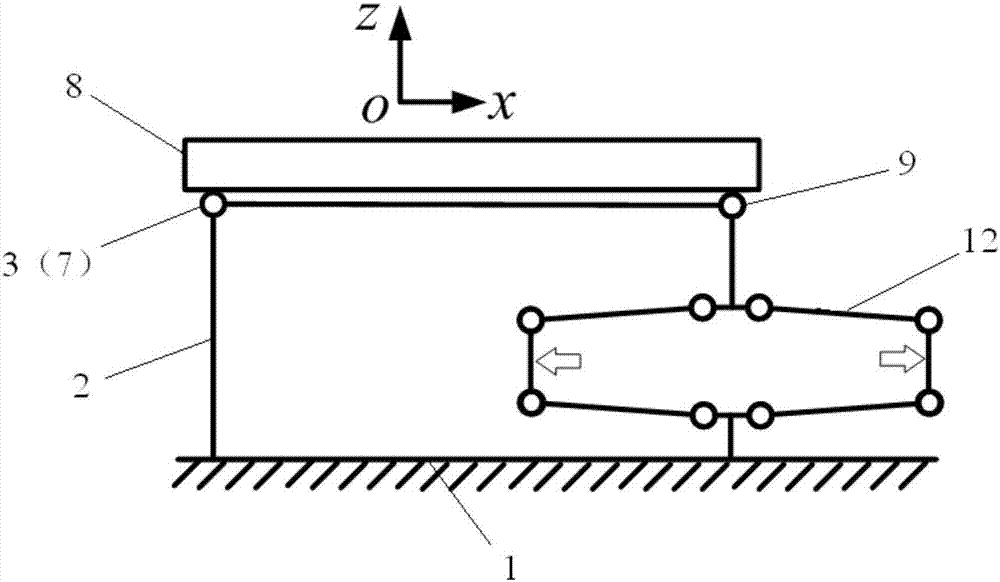

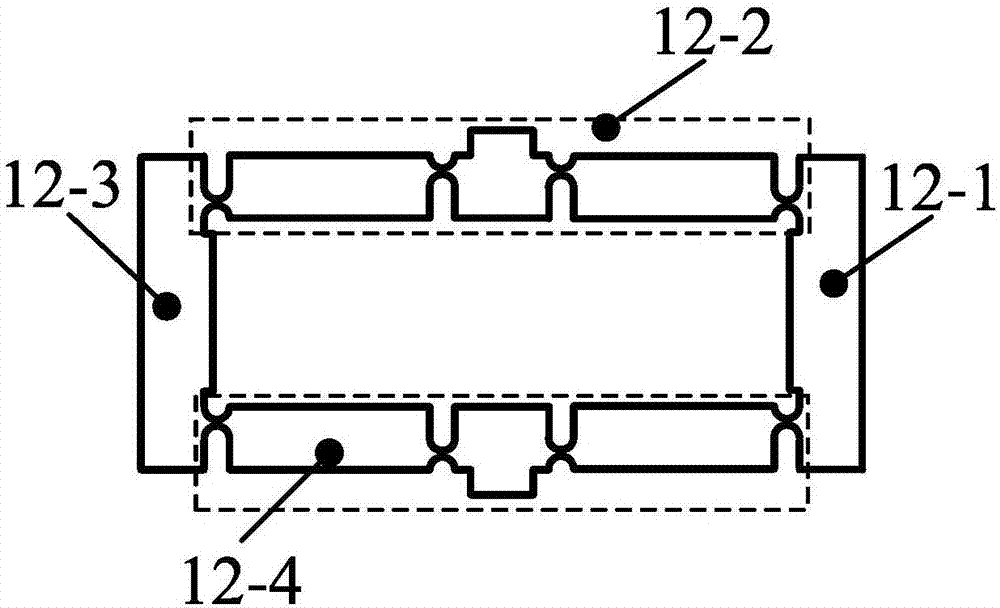

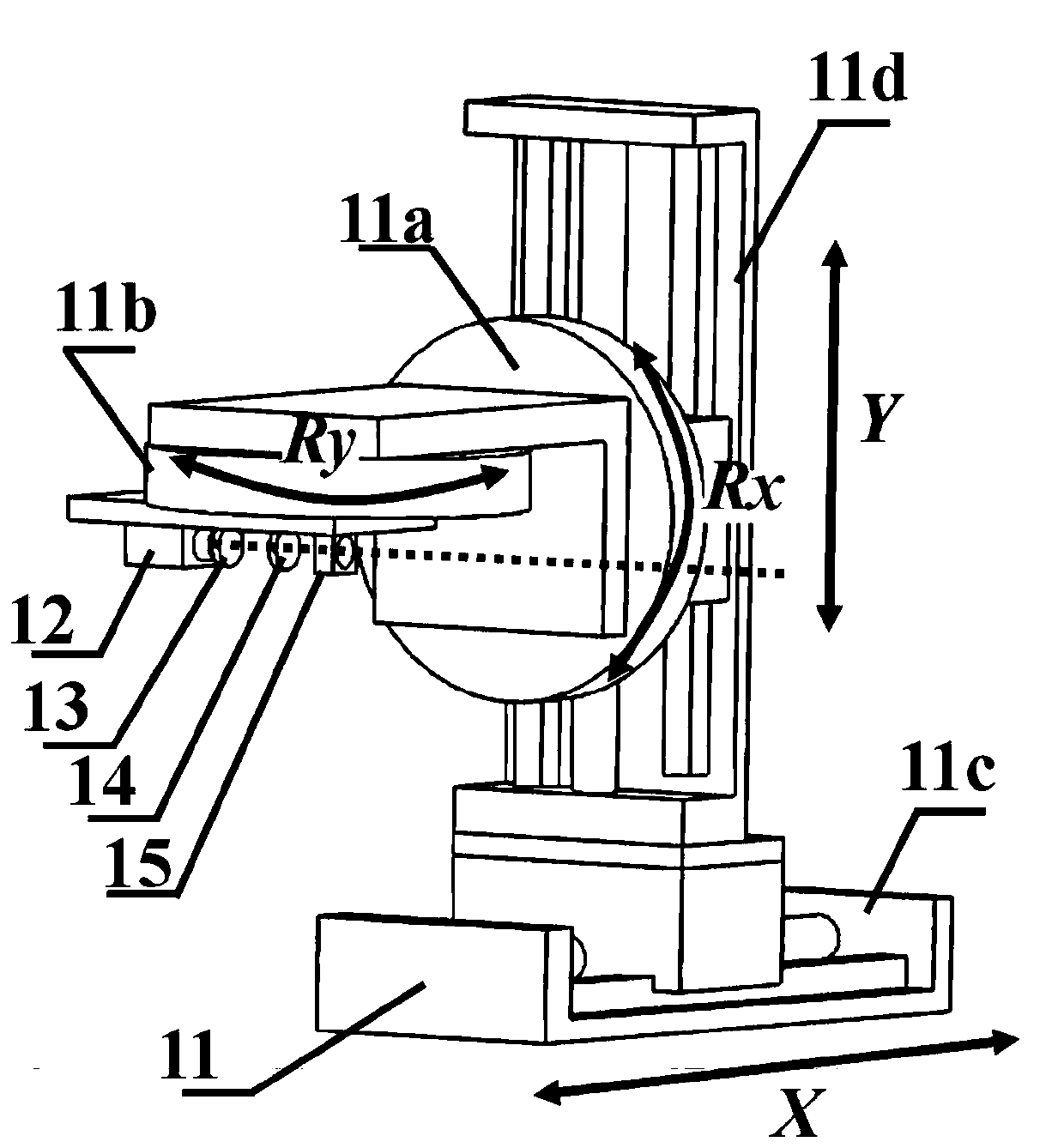

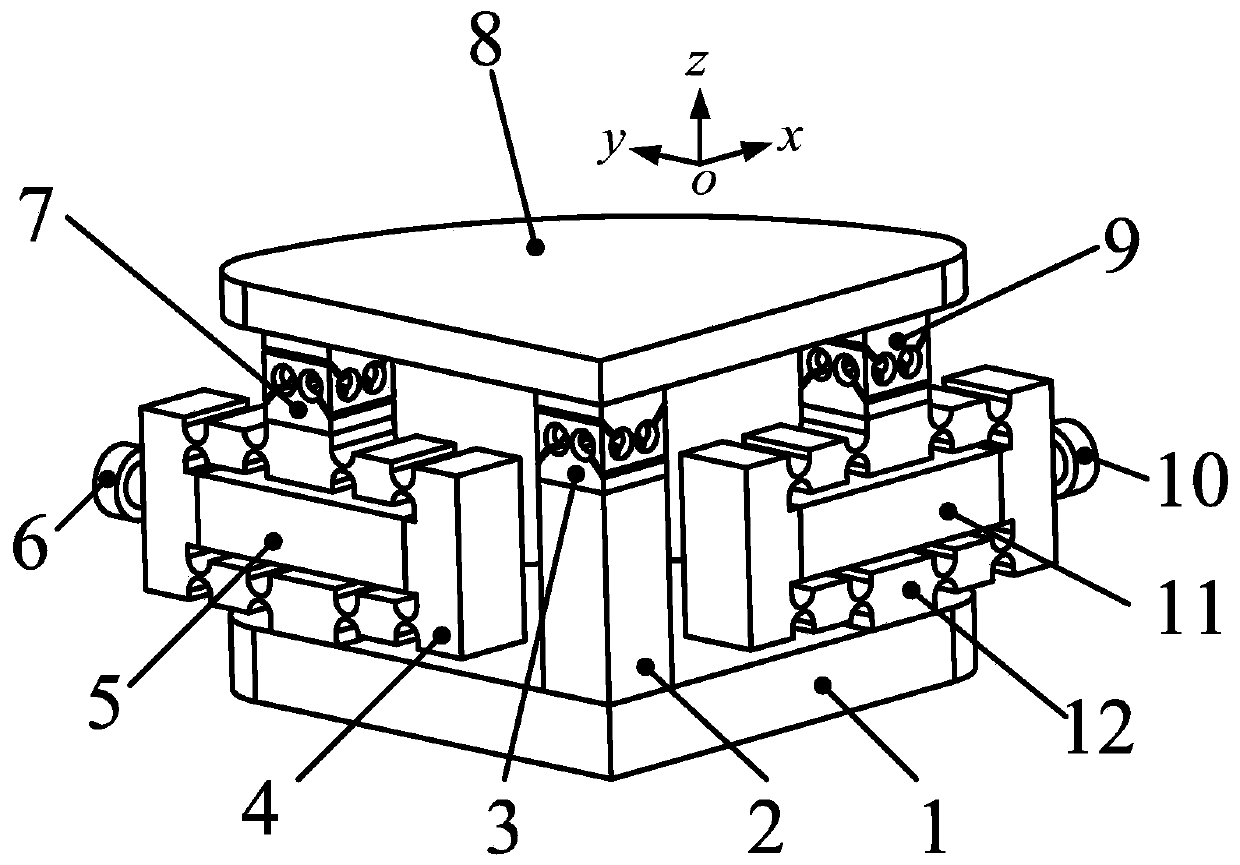

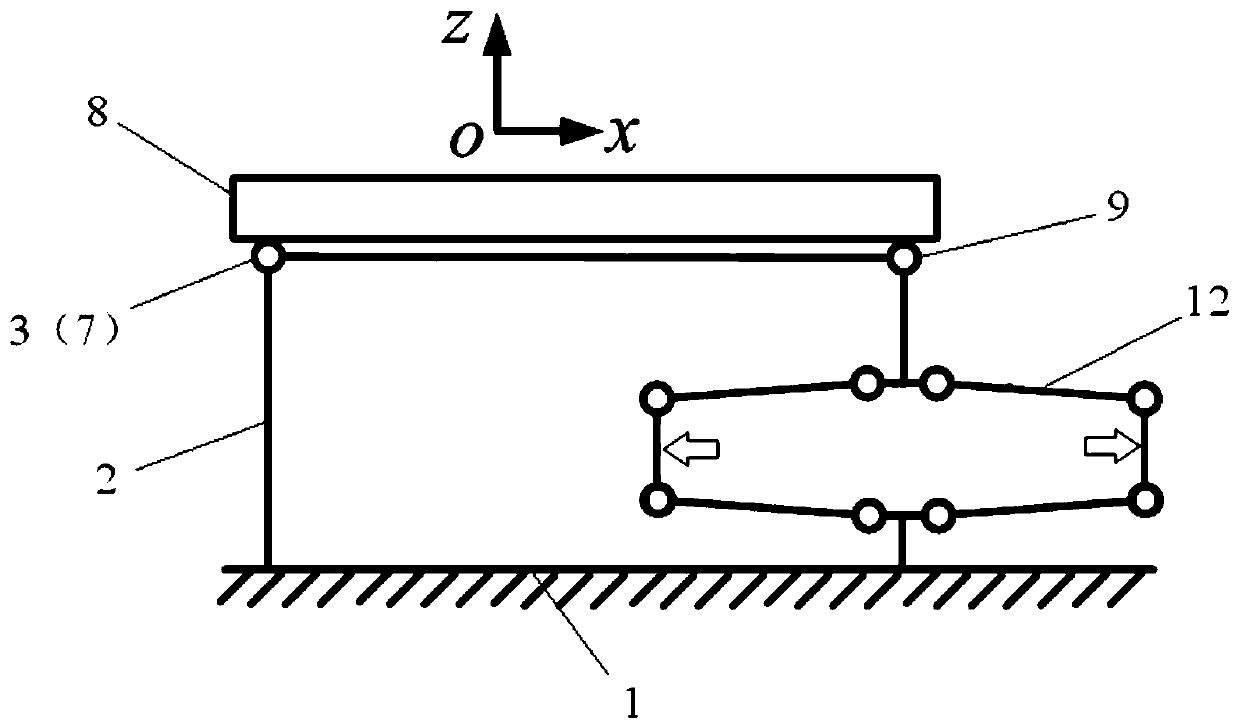

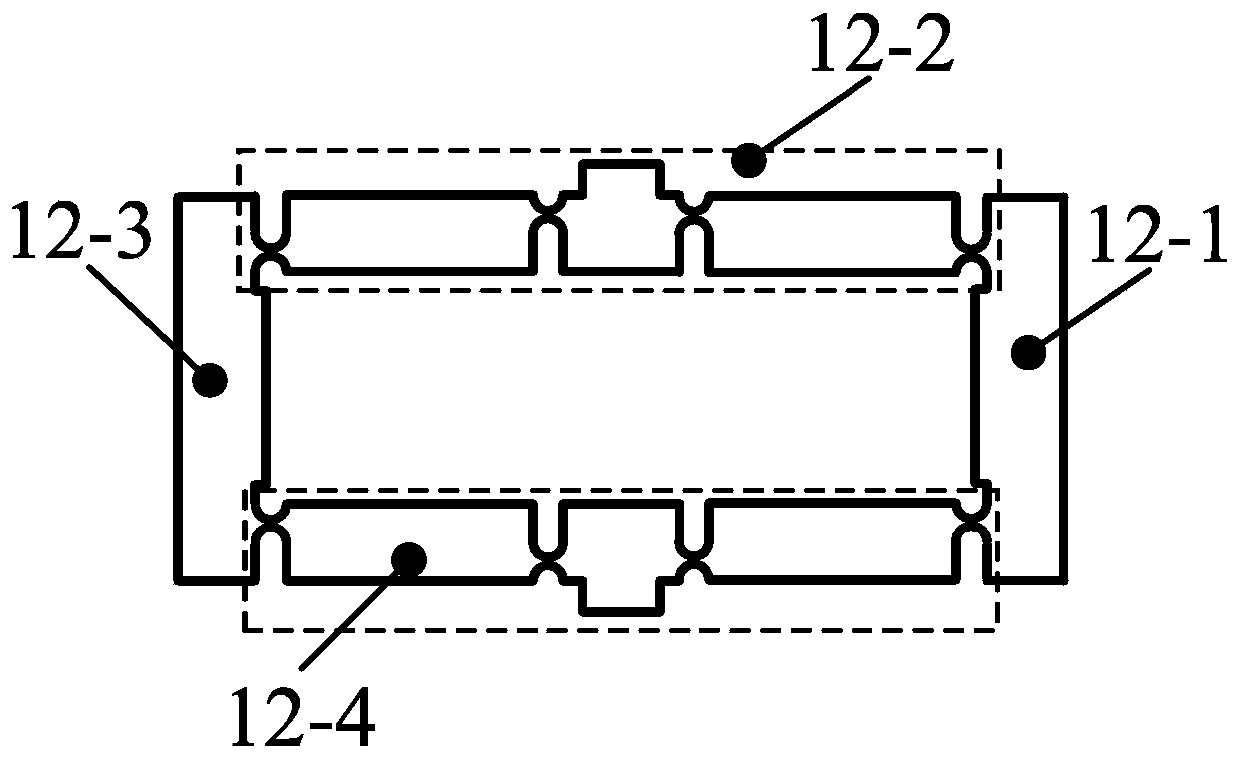

Piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform

The invention discloses a piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform. The piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform comprises a base, a stand column, a decoupling hook hinge, an X-axis bridge type amplification mechanism, an X-axis piezoelectric ceramic driver, an X-axis pre-tightening bolt, an X-axis hook hinge, a Y-axis bridge type amplification mechanism, a Y-axis piezoelectric ceramic driver, a Y-axis pre-tightening bolt, a Y-axis hook hinge and a working platform. The X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism are mounted on the outer sides of the two sides of the base. The vertex distances of the X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism and the base are equal, the X-axis piezoelectric ceramic driver is mounted in the X-axis bridge type amplification mechanism through the X-axis pre-tightening bolt, and the Y-axis piezoelectric ceramic driver is mounted in the Y-axis bridge type amplification mechanism through the Y-axis pre-tightening bolt. Each of the X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism comprises flexible hinge mechanisms symmetrically arranged on the two sides of the X-axis piezoelectric ceramic driver or the Y-axis piezoelectric ceramic driver and a beam for connecting the bridge type flexible hinge mechanisms. The X-axis bridge type amplification mechanism is connected with the working platform through the X-axis hook hinge, and the Y-axis bridge type amplification mechanism is connected with the working platform through the Y-axis hook hinge. By the adoption of the piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform, the two-degrees-of-freedom decoupling precision slight swing can be achieved.

Owner:TIANJIN UNIV

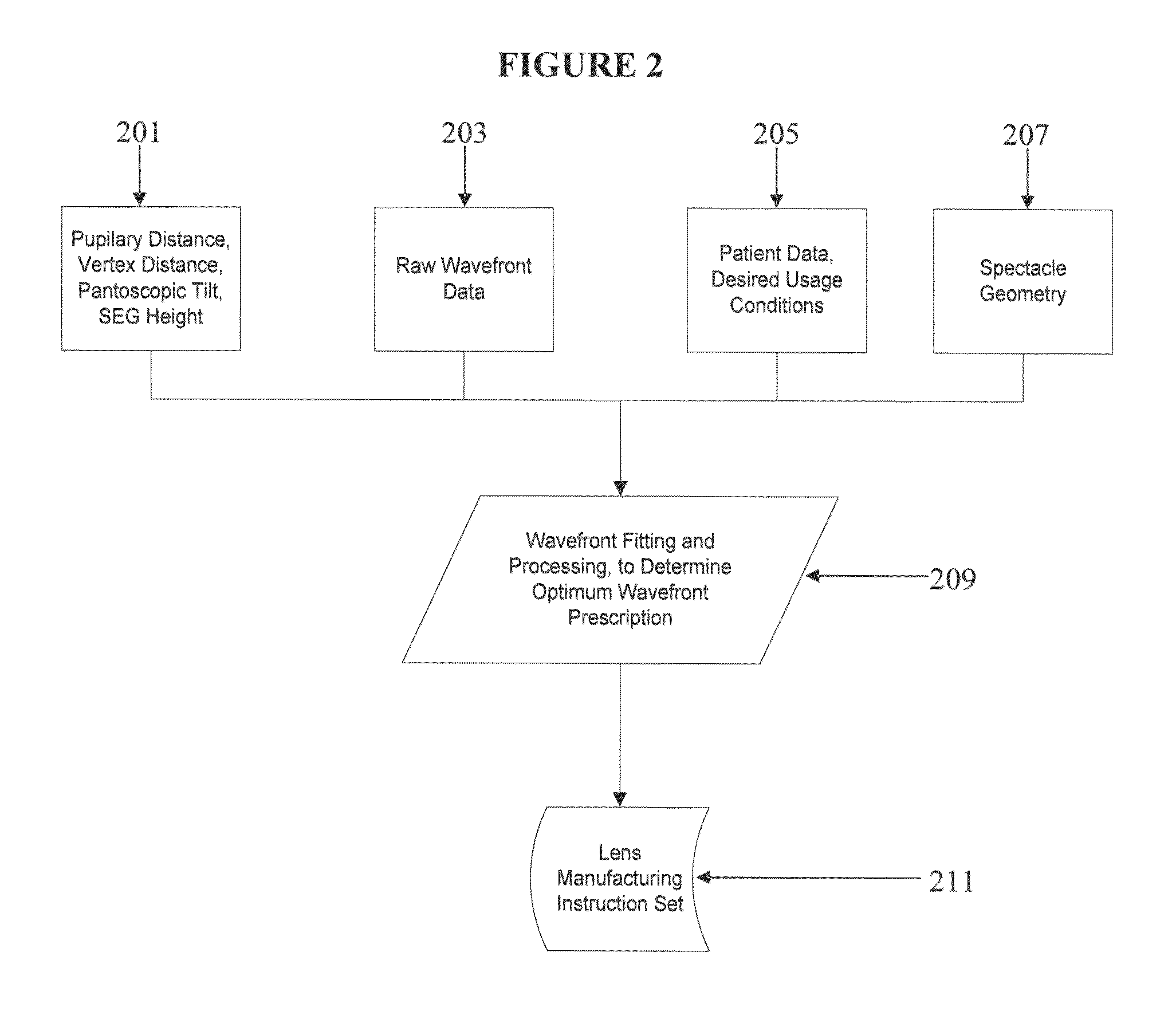

Methods of designing progressive addition lenses

Embodiments of the invention pertain to a method for producing a spectacle lens with optimal correction across the entire lens that take the patient's complete measured wavefront into account. Specific embodiments also consider one or more additional factors such as vertex distance, intermediate power, add power, segmental fitting height, pantoscopic tilt, and use conditions. The lens wavefront can be achieved by optimizing a corrected wavefront, where the corrected wavefront is the effect of the patient's measured wavefront and / or the lens wavefront. The optimization of the corrected wavefront can involve representing the measured wavefront and / or the lens wavefront on a grid. In an exemplary embodiment, the grid can lie in a plane. During the optimization, a subset of the grid can be used for the representation of the measured wavefront at a point on the grid so that the portions of the measured wavefront that contribute to the corrected wavefront at that point on the grid are taken into account. The progressive addition lens can be utilized for distance, intermediate and reading use wherein the power progression is non-linear in any number or all of the near, intermediate, and far zones.

Owner:ESSILOR INT CIE GEN DOPTIQUE

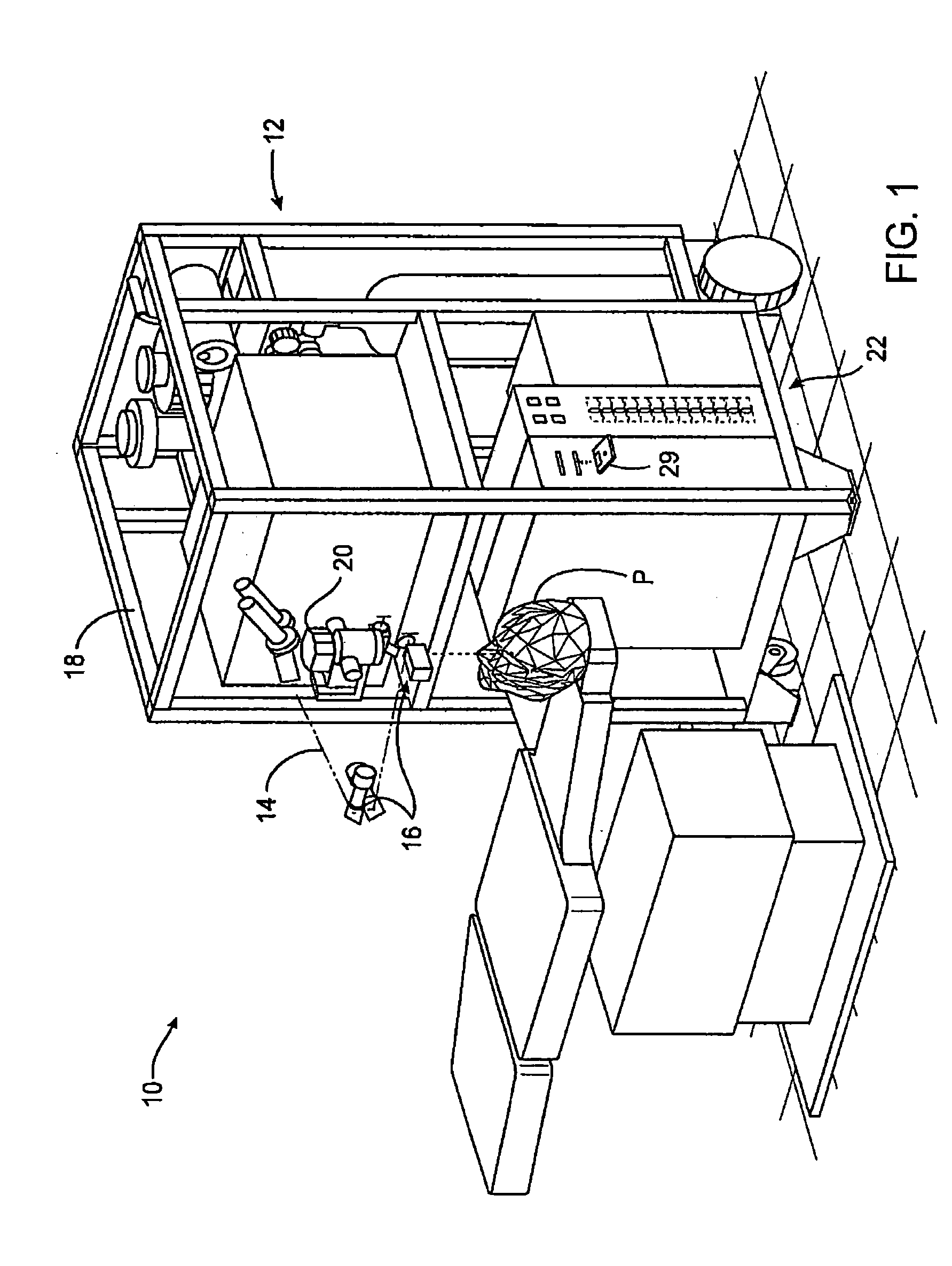

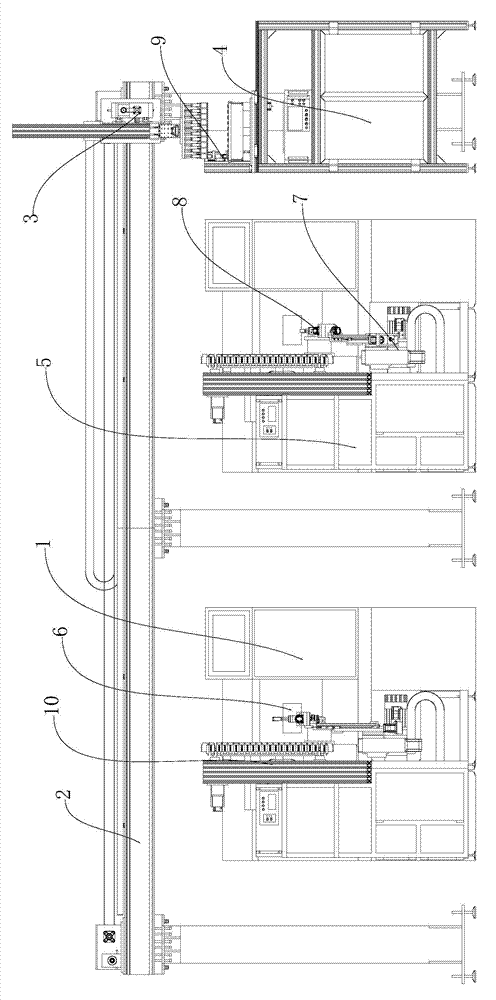

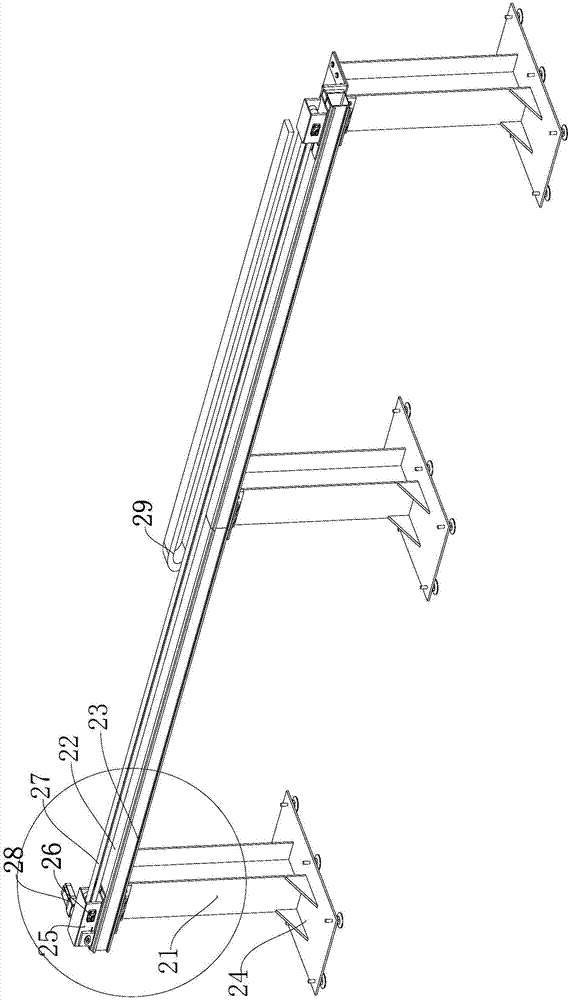

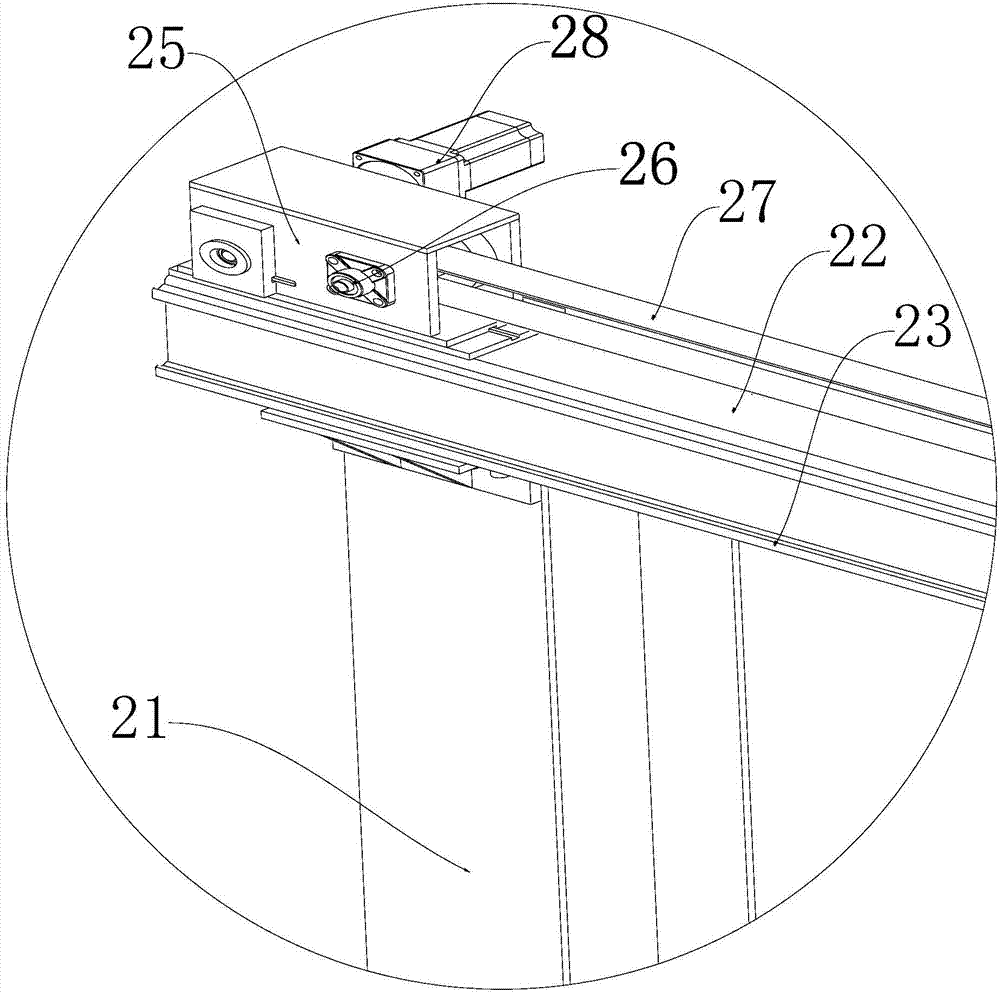

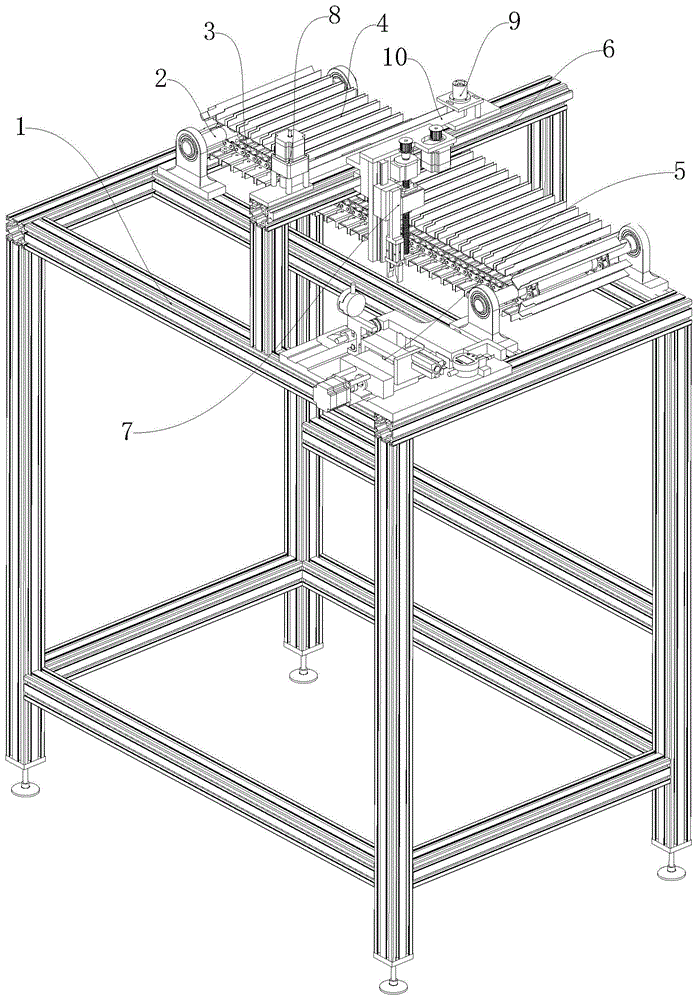

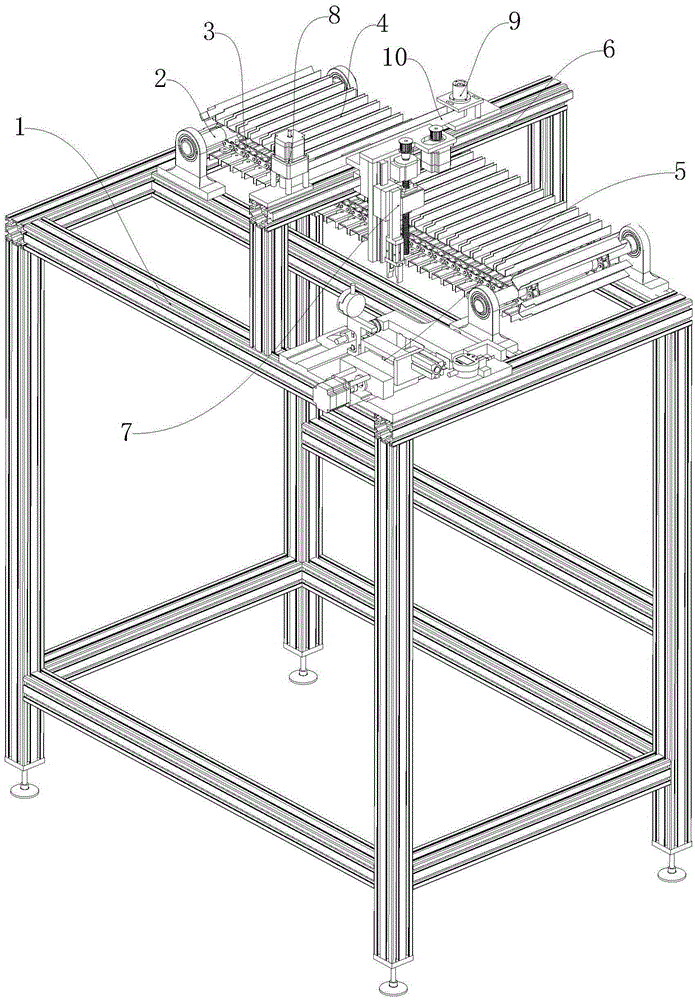

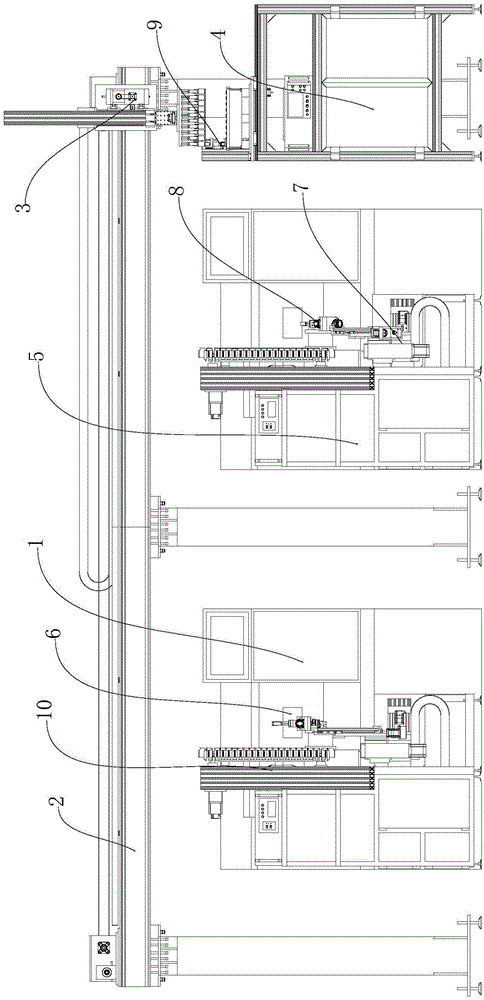

Automatic PXE piston production line

ActiveCN103769823AGuaranteed machining accuracyReduce investmentProgramme-controlled manipulatorGripping headsMeasuring instrumentEngineering

The invention relates to the field of machining equipment, and particularly discloses an automatic PXE piston production line which is high in production efficiency and good in machining precision. The automatic PXE piston production line comprises machine tools and a gate-type transmission mechanism. A gate-type mechanical arm is arranged on the gate-type transmission mechanism, the two machine tools are arranged on the lower portion of the gate-type transmission mechanism at intervals, one end of the gate-type transmission mechanism is provided with a double-machine-material library, and the front faces of the machine tools are provided with multifunctional machine frames. Each multifunctional machine frame is provided with a single-machine-material library and a mechanical arm transmission mechanism, each mechanical transmission mechanism is provided with a PXE piston mechanical arm jig, and a main shaft inside each machine tool is provided with a PXE piston machining jig. According to the automatic PXE piston production line, pistons can be automatically fed, clamped and discharged through the mechanical arms, the automation effect is good, the machining efficiency can be improved, the investment on workers is reduced, production cost is lowered, and the machining precision of the pistons can be guaranteed through an automatic PXE piston measuring instrument which is used for measuring the ball vertex distance and the assembly of the pistons.

Owner:ZHEJIANG YIFENG MACHINERY

Method of designing progressive addition lenses

Embodiments of the invention pertain to a method for producing a spectacle lens with optimal correction across the entire lens taking into account the patient's complete measured wavefront. Specific embodiments can also take into account one or more additional factors such as vertex distance, segmental fitting height, pantoscopic tilt, and use conditions. The lens wavefront can be achieved by optimizing a corrected wavefront, where the corrected wavefront is the combined effect of the patient's measured wavefront and the lens wavefront. The optimization of the corrected wavefront can involve representing the measured wavefront and the lens wavefront on a grid. In an embodiment, the grid can lie in a plane. During the optimization, a subset of the grid can be used for the representation of the measured wavefront at a point on the grid so as to take into account the portions of the measured wavefront that contribute to the corrected wavefront at that point on the grid.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Methods of designing progressive addition lenses

Embodiments of the invention pertain to a method for producing a spectacle lens with optimal correction across the entire lens that take the patient's complete measured wavefront into account. Specific embodiments also consider one or more additional factors such as vertex distance, intermediate power, add power, segmental fitting height, pantoscopic tilt, and use conditions. The lens wavefront can be achieved by optimizing a corrected wavefront, where the corrected wavefront is the effect of the patient's measured wavefront and / or the lens wavefront. The optimization of the corrected wavefront can involve representing the measured wavefront and / or the lens wavefront on a grid. In an exemplary embodiment, the grid can lie in a plane. During the optimization, a subset of the grid can be used for the representation of the measured wavefront at a point on the grid so that the portions of the measured wavefront that contribute to the corrected wavefront at that point on the grid are taken into account. The progressive addition lens can be utilized for distance, intermediate and reading use wherein the power progression is non-linear in any number or all of the near, intermediate, and far zones.

Owner:ESSILOR INT CIE GEN DOPTIQUE

System, method and apparatus for enabling corneal topography mapping by smartphone

An apparatus for enabling corneal topography includes an attachment to align a placido disc illumination system with a camera of a mobile communication device. The placido disc illumination system generates concentric rings and reflects the concentric rings off a cornea. A portion of the reflected concentric rings are utilized to confirm vertex distance. The apparatus further comprises a memory, a processor, and computer-readable instructions in a mobile communication device. The camera captures an image of reflected concentric rings and communicates the captured image of the reflected concentric rings to an external computing device. A method for performing corneal topography utilizes a mobile computing and / or communication device, projects a plurality of peripheral concentric rings onto a subject's cornea and projects center rings onto the subject's cornea. The method further includes capturing, via a smartphone camera, an image of the projected peripheral concentric rings and the center rings.

Owner:INTELLIGENT DIAGNOSTICS LLC

The drag reduction method of thixotropic mud

ActiveCN104534167BReduce frictional resistanceImprove drag reduction efficiencyPipe laying and repairCarboxymethyl celluloseSlurry

The invention discloses a drag reduction method of thixotropic slurry, and belongs to the technical field of civil engineering. The method includes the steps: firstly, preparing the thixotropic slurry for drag reduction; secondly, placing stirred thixotropic slurry into a slurry storage tank, forming a grouting hole and connecting a grouting pipeline; thirdly, calculating grouting pressure and selecting a grouting pump; finally, performing grouting. The thixotropic slurry comprises sodium bentonite, carboxymethyl cellulose, sodium carbonate, clean water and an appropriate amount of admixture. Frictional drag of a pipe and soil is decreased by a grouting process, the vertex distance can be increased by 40%-70% after lubrication and drag reduction by the grouting process, drag of a top pipe in work can be effectively reduced, the top pipe with a large caliber and a long distance can continuously extend, and the drag reduction method has the advantages of low cost, easiness in technical implementation and high drag reduction efficiency.

Owner:CHINA MCC17 GRP

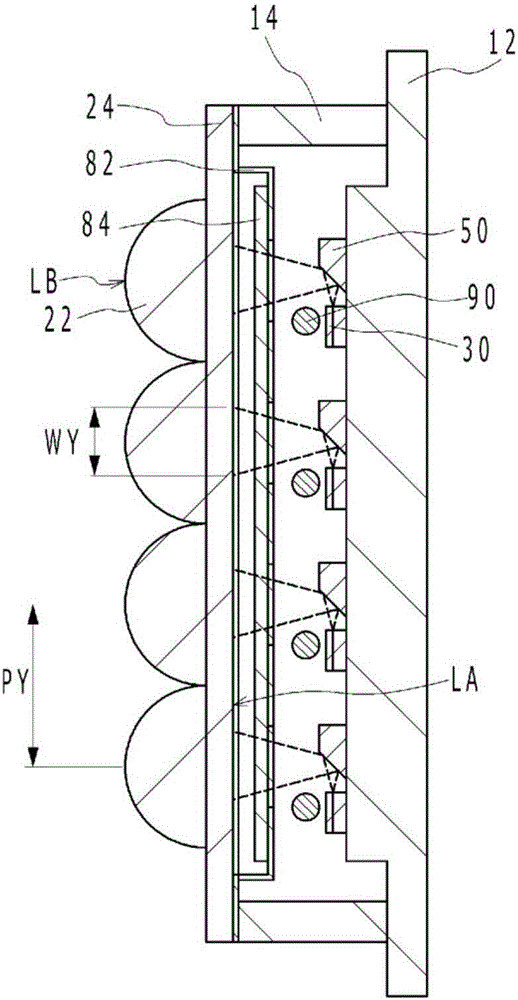

Light-emitting device

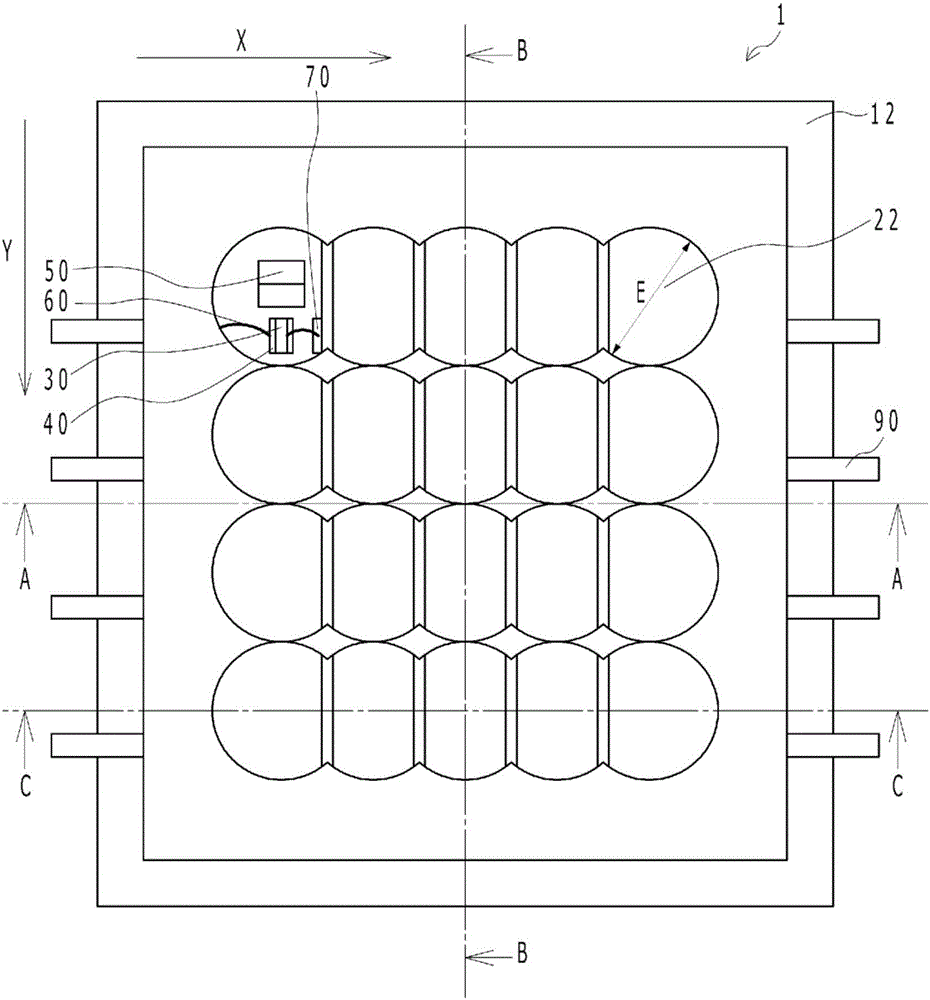

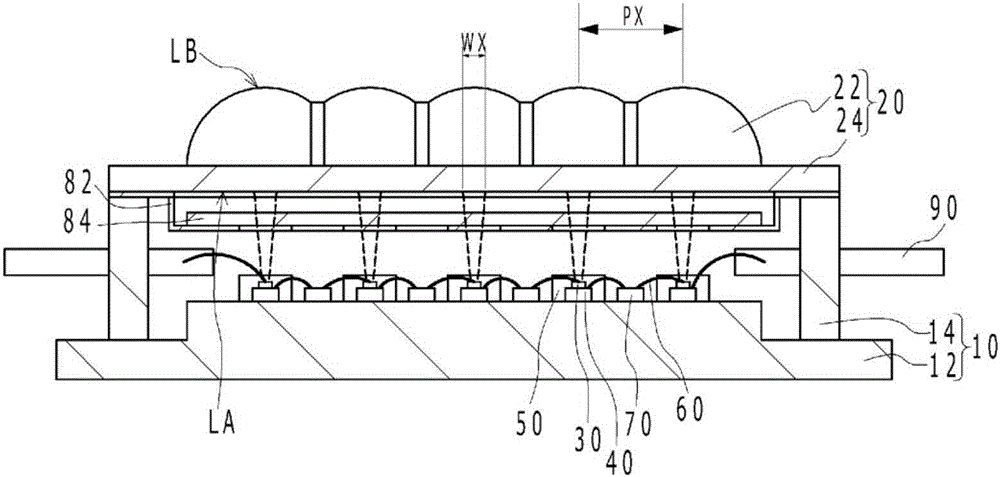

The invention provides a light-emitting device in which no significant deviation may occur in a positional relationship between the light sources and the lens elements when the collimator lens array is mounted only slightly rotated from a prescribed direction, and, consequently, an intensity distribution of light emitted from the collimator lens array may not change. The light-emitting device includes a substrate; a lens array having a plurality of lens sections in a matrix pattern; and a plurality of semiconductor laser elements disposed on the substrate. Each of the semiconductor laser elements emits a respective laser beam, each laser beam having a beam shape with a greater width in a column direction than in a row direction on a light incident surface of each respective lens section. The lens sections have an inter-vertex distance in the row direction that is smaller than both (i) a maximum outer diameter of each of the lens sections, and (ii) an inter-vertex distance in the column direction. A curvature of the lens sections in the row direction is the same as a curvature of the lens sections in the column direction.

Owner:NICHIA CORP

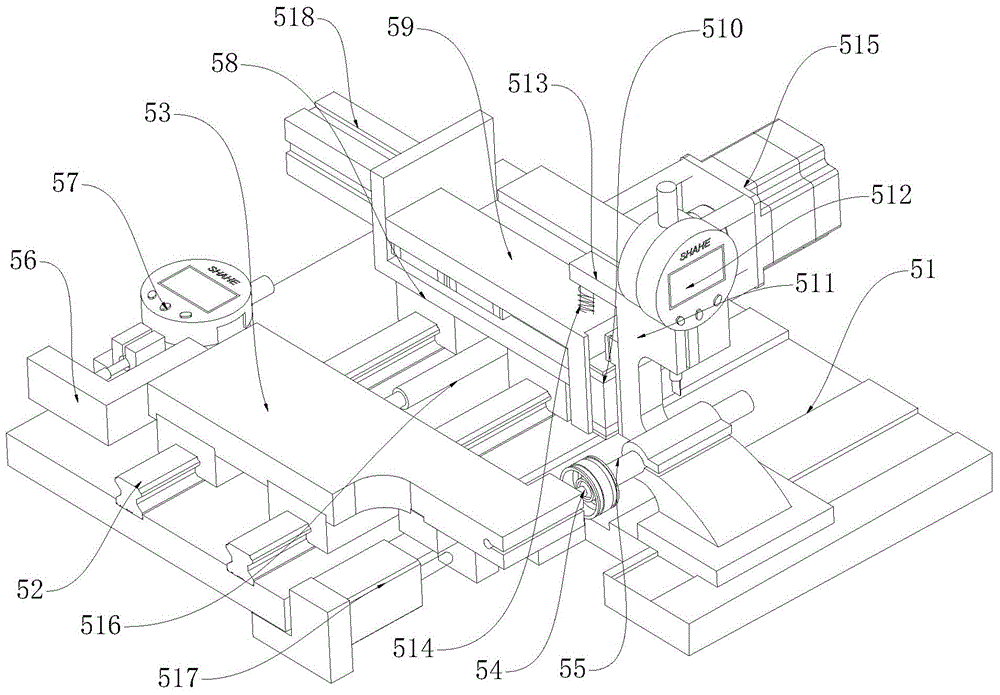

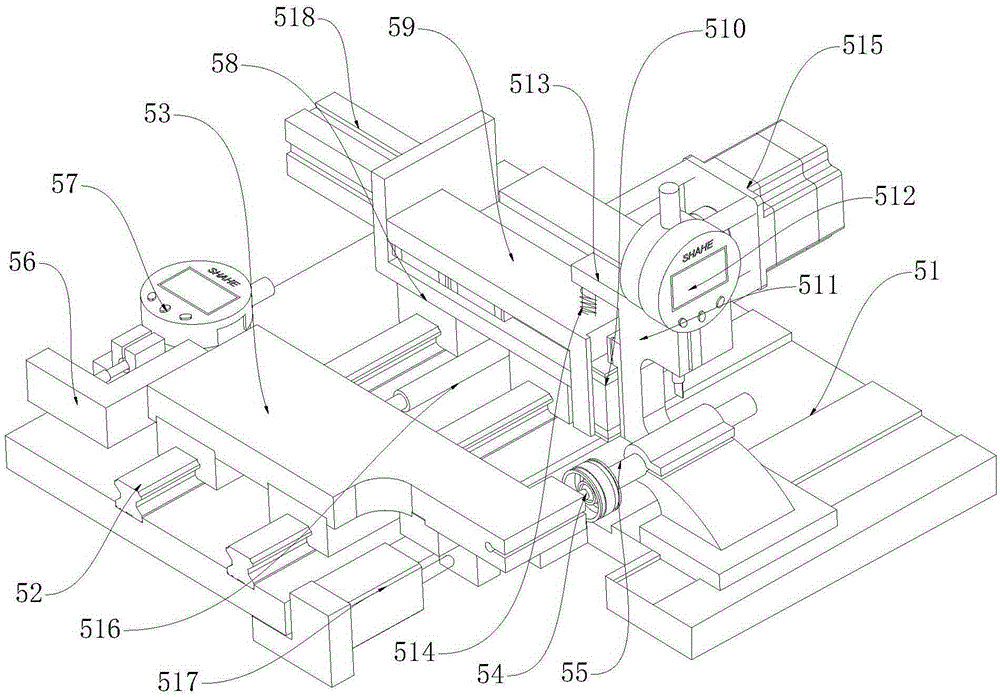

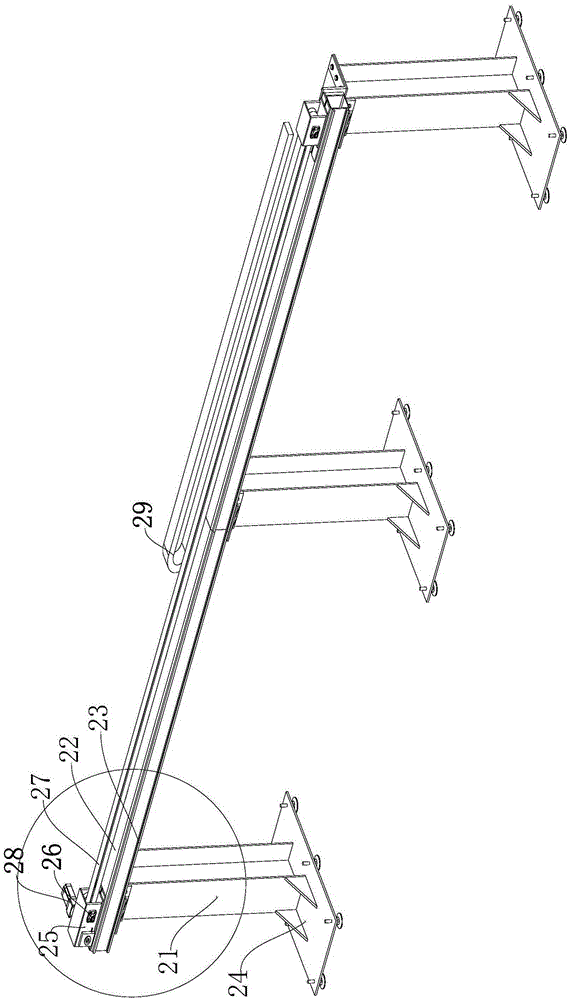

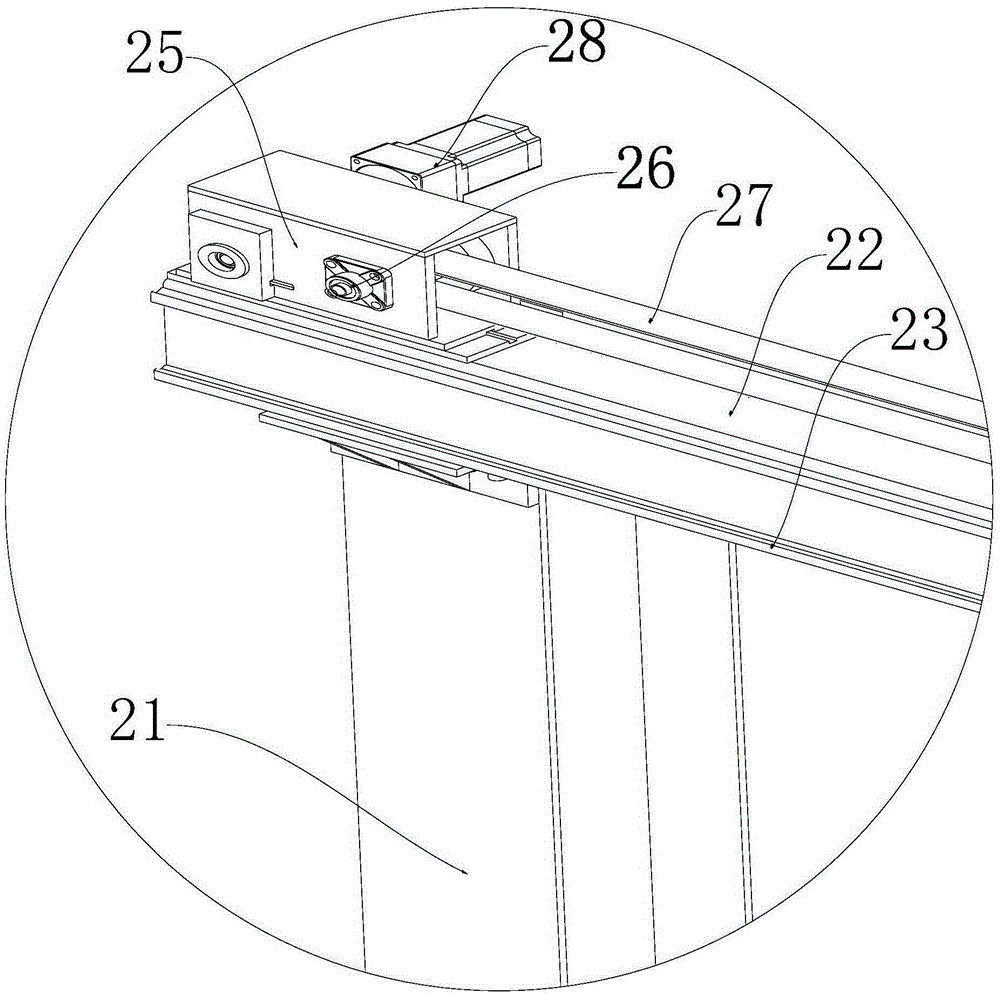

Piston automatic measurement storage device

ActiveCN103604406APrecise positioningWith self-locking abilityMeasurement devicesMeasurement precisionVertex distance

The invention relates to the piston machining equipment field, especially a high-measurement precision piston automatic measurement storage device with a storage function. The piston automatic measurement storage device comprises a detecting rack; two ends of one side of the detecting rack are provided with two rotating shafts; the rotating shafts are provided with endless chain groups in a matched manner; rectangular grooves are arranged side by side on the endless chain groups; one end of the detecting rack is provided with a detection mechanism which is located at side edges of the rectangular grooves; a transverse slide rail is arranged above the detection mechanism; and the transverse slide rail is provided with a vertically-downward pneumatic clamping claw which can move horizontally. According to the piston automatic measurement storage device, the endless chain groups and the rectangular grooves are arranged at one side of the detecting rack, and therefore, machined pistons can be temporally stored, and the transmission of the pistons can be realized; and in a transmission process, the pistons can be grabbed in a sampling manner through the pneumatic clamping claw, and sphere vertex distance detection and groove inner diameter detection are carried out on the detection mechanism simply and conveniently; since the sphere vertex distance detection and groove inner diameter detection can be performed simultaneously, detection steps can be greatly reduced, and detection efficiency can be improved, and the quality of the pistons can be ensured.

Owner:TONGXIANG HENGTAI PRECISION MACHINERY

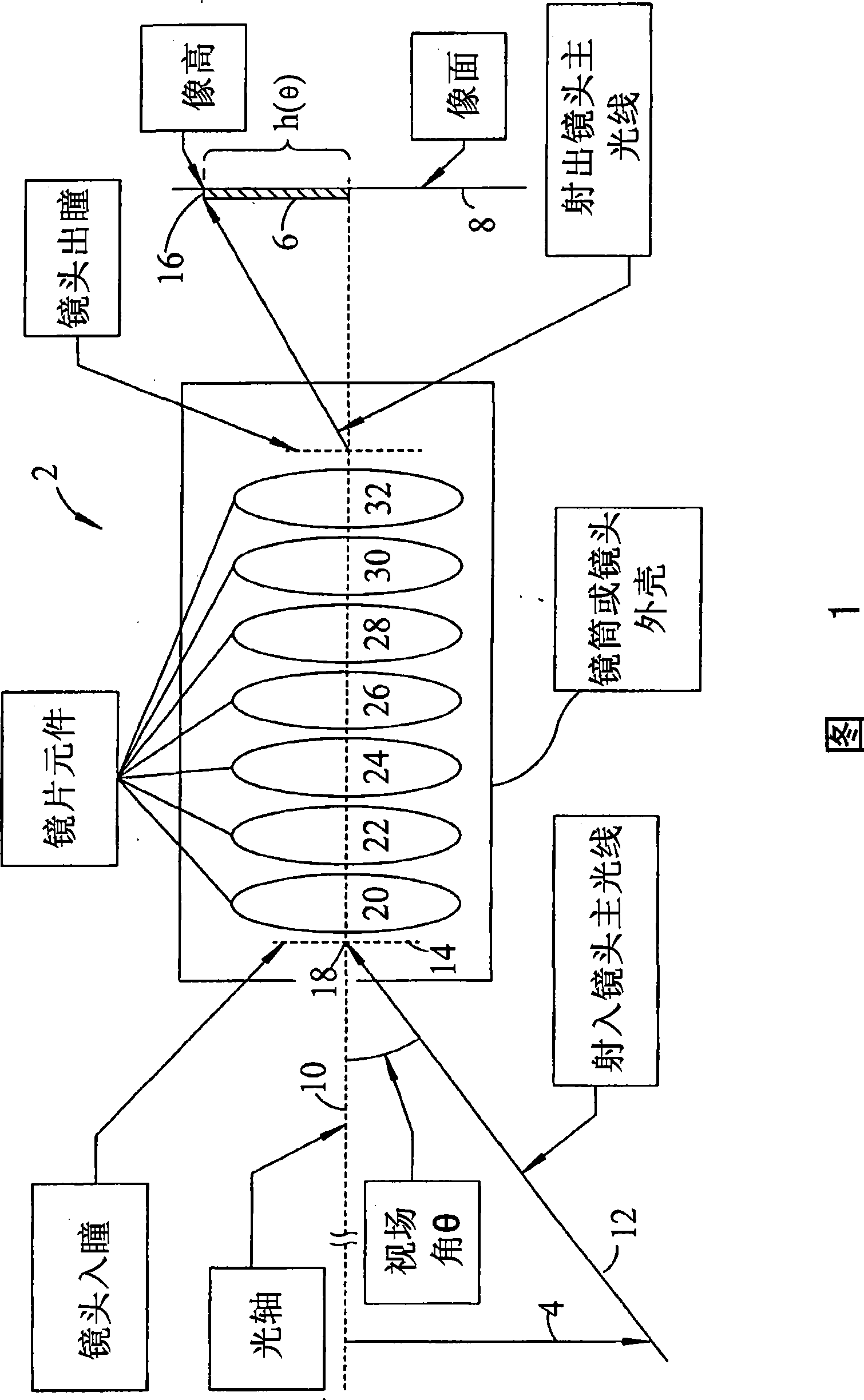

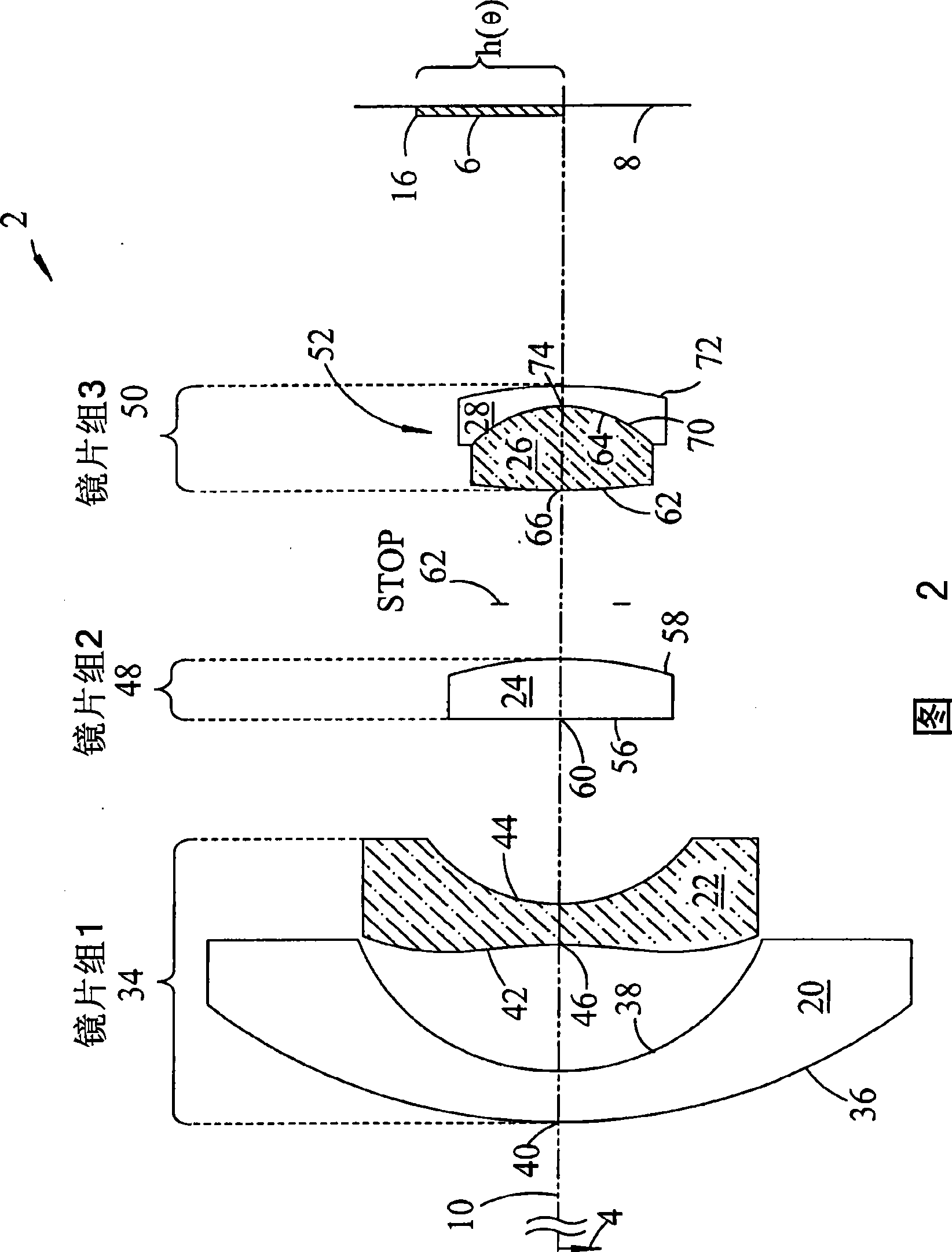

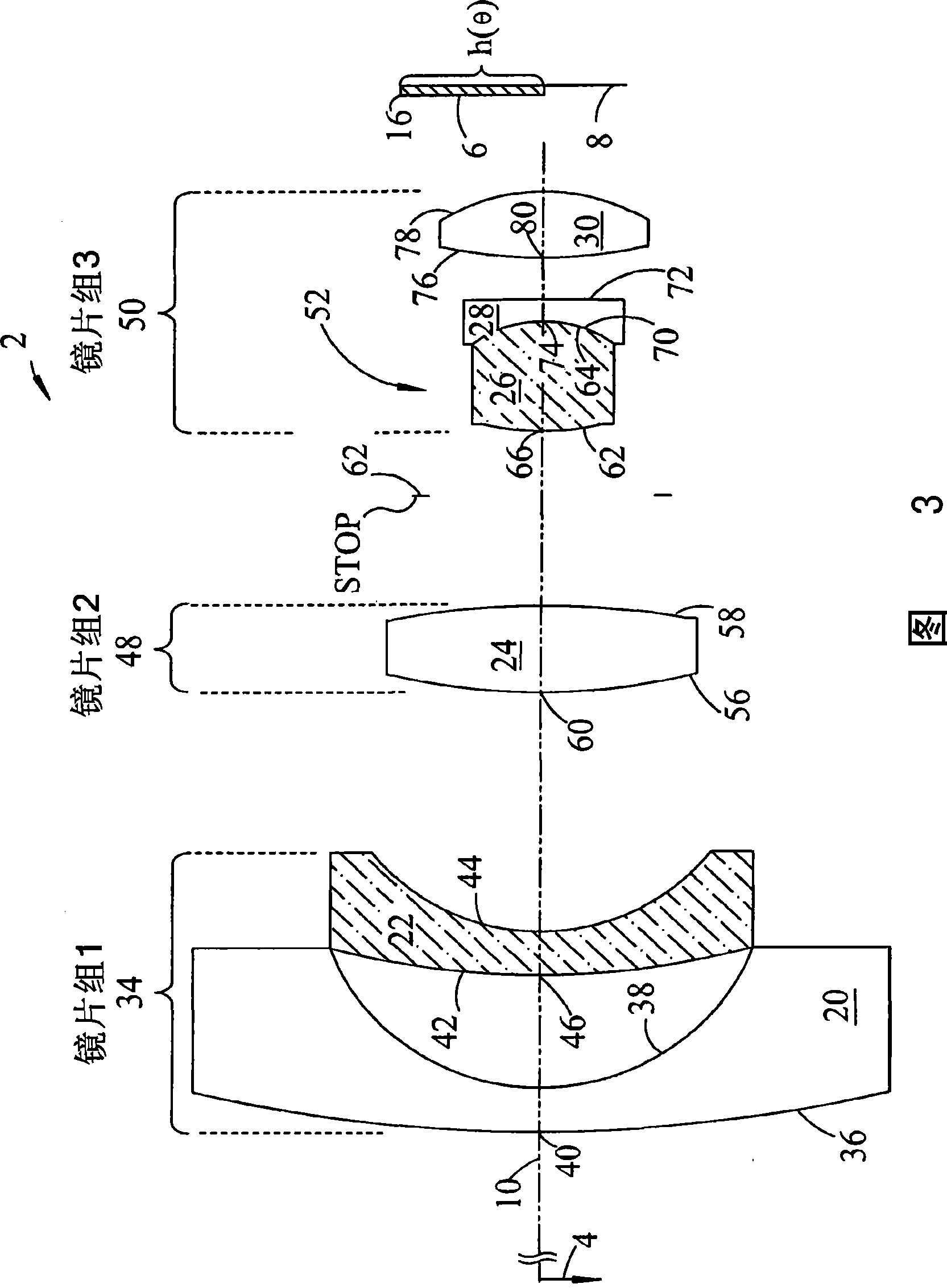

Ultra-wide angle objective lens

A ultra-wide angle objective lens comprising a first group having a first lens element having a convex object surface facing the object and a concave image surface facing the image plane, and a second aspheric lens element, the second aspheric lens element having a varying power that is negative at its vertex; and that increases positively with radial distance from the vertex. A second group has at least one lens element and a positive power. A third group has at least a first and a second lens element and a positive power. The ratio of the total track to the focal length satisfies the condition that TT / fo = < 33 and the image height on a focal plane is h(theta) > f*theta, where h(theta) is the image height formed by an off-axis chief ray having a field angle theta, and f is the effective focal length of the lens.

Owner:阿里克斯·宁

Customized z-lens design program

Embodiments of the invention pertain to a method for producing a spectacle lens with optimal correction across the entire lens taking into account the patient's complete measured wavefront. Specific embodiments can also take into account one or more additional factors such as vertex distance, SEG height, pantoscopic tilt, and use conditions. The lens wavefront can be achieved by optimizing a corrected wavefront, where the corrected wavefront is the combined effect of the patient's measured wavefront and the lens wavefront. The optimization of the corrected wavefront can involve representing the measured wavefront and the lens wavefront on a grid. In an embodiment, the grid can lie in a plane. During the optimization, a subset of the grid can be used for the representation of the measured wavefront at a point on the grid so as to take into account the portions of the measured wavefront that contribute to the corrected wavefront at that point on the grid.

Owner:OPHTHONIX

Projection system and lens combination

The invention provides a projection system comprising two groups of lenses, wherein the first group of lenses is provided with a first focal length used for forming a first image by focusing incident light rays, and the second group of lenses is provided with a second focal length used for projecting the first image into a second image; a lens vertex distance is spaced between the two groups of lenses and is correlative to a light path between the first group of lenses and the second group of lenses; the second focal length is less than or equal to the lens vertex distance, and the difference of the lens vertex distance and the second focal length is less than or equal to half of the first focal length. The invention also provides a lens combination.

Owner:QISDA CORP

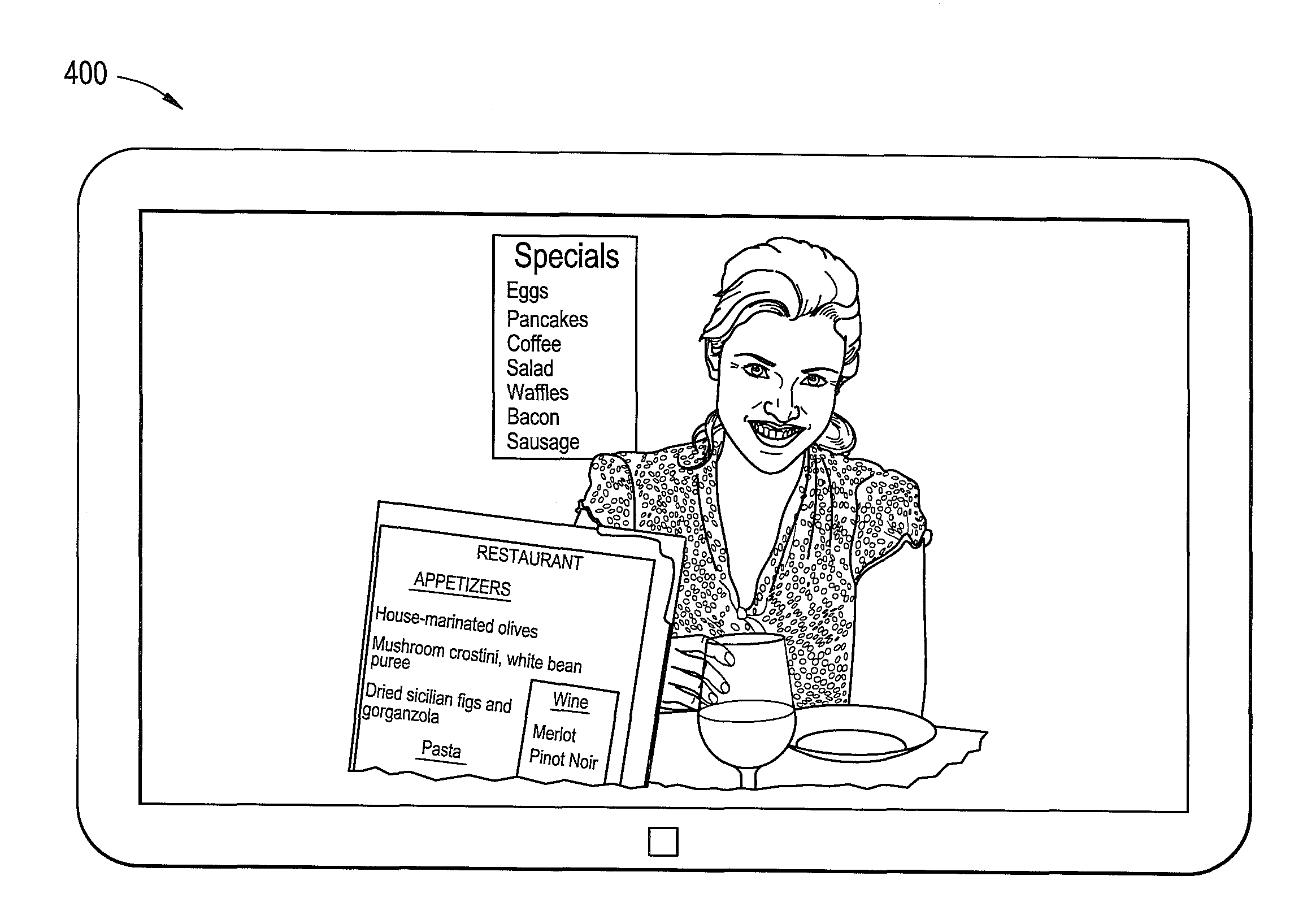

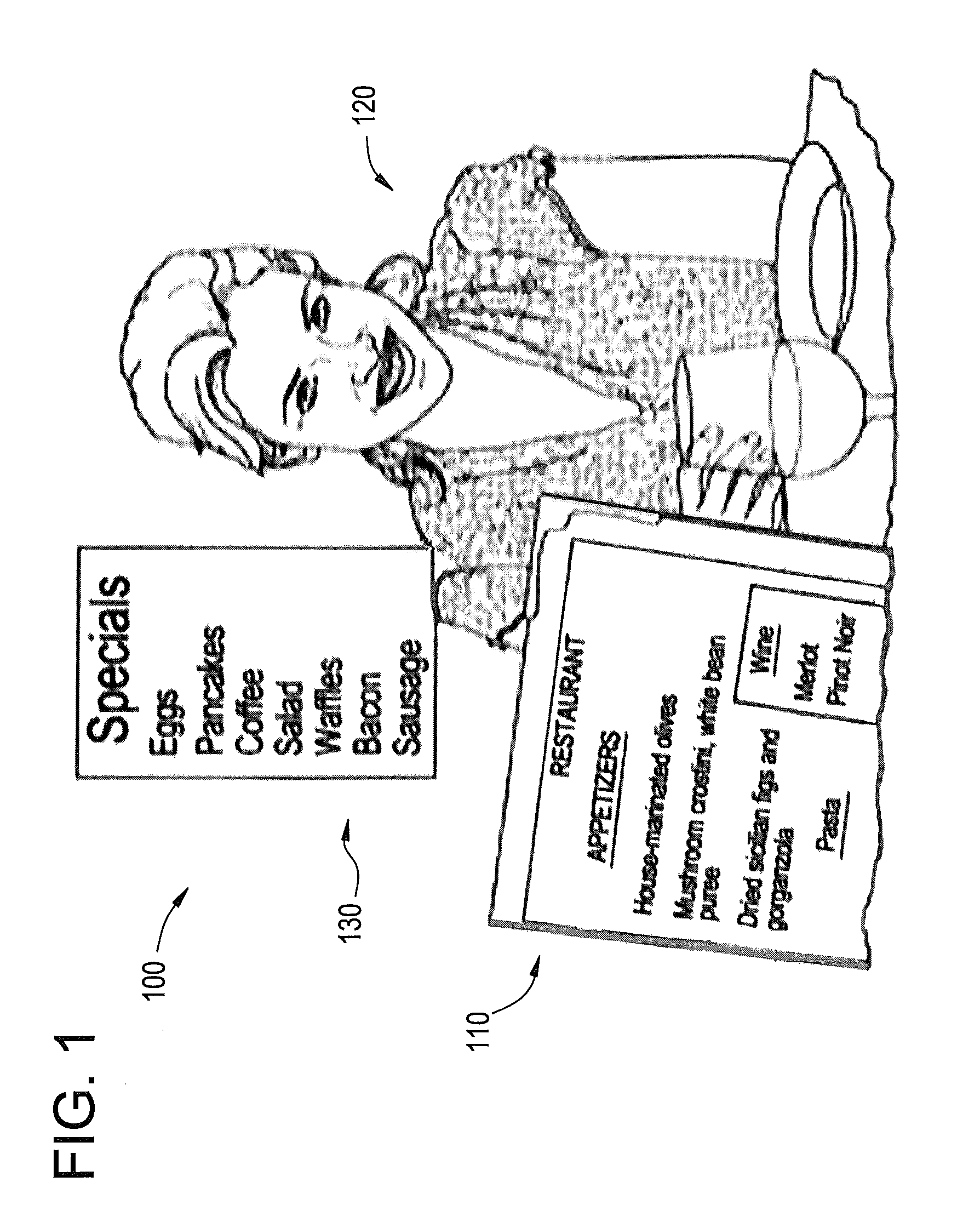

Patient interactive fit tool and methodology for contact lens fitting

An interactive fit tool and methodology which may be utilized by an eye care professional to improve the efficiency and final outcome in selecting a pair of contact lenses targeted towards a specific patient visual need in the treatment of presbyopia. The interactive fit tool comprises an application which includes images that would allow a patient to decide if he or she desires balanced visual acuity, near biased visual acuity, or distance biased visual acuity. In addition, the interactive fit tool comprises fit guide tables and performs the calculations for vertex distance and spherical equivalent.

Owner:JOHNSON & JOHNSON VISION CARE INC

A blind area coverage method for underwater wireless sensor networks

ActiveCN104135731BIncrease coverageLow mobile costNetwork topologiesNetwork planningDodecahedronData acquisition

The invention discloses a blind area covering method of an underwater wireless sensor network, which belongs to the technical field of underwater wireless sensor networks. This method uses the movement of autonomous underwater vehicles to collect the monitoring data of the coverage blind area of the underwater wireless sensor network. The distance between the grid center and the vertex is equal to the coverage radius of the autonomous underwater vehicle; then each grid is traversed with an appropriate strategy, so as to realize the data collection of the blind area. The algorithm overcomes the problems of complex and unknown underwater environment, diverse coverage scenarios and difficulty in reliable coverage, and at the same time minimizes the cost of autonomous underwater vehicle path movement.

Owner:NANJING UNIV OF POSTS & TELECOMM

A method and device for detecting ophthalmic lenses based on wavefront analysis

InactiveCN107577065BEfficient measurementRealize detectionSpectales/gogglesTesting optical propertiesOphthalmologyImaging quality

The invention discloses a method for detecting spectacle lenses based on wavefront analysis. The method comprises a light source adjustment unit, a lens posture adjustment unit, a detection unit and asoftware module, wherein the light source adjustment unit is used to translate and rotate incident light; the lens posture adjustment unit is used to adjust initial vertex distances of lenses, a wearing view angle and facial radians of rings according to wearing parameters of a prescription for spectacles; the detection unit is used to detect an effective wavefront aberration of the lenses; the software module is used to set motion parameters of a motion platform and set detection parameters of a wavefront aberration sensor in the detection unit, and is used to receive, calculate and displayeffective wavefront aberration data of the detection unit. The method measures the effective wavefront aberration in high precision in a lens wearing state, and provides quantitative reference for designing and processing of the lenses and evaluation of optical properties and imaging quality.

Owner:TIANJIN UNIV

A piezoelectric driven two-degree-of-freedom decoupling micro-swing platform

The invention discloses a piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform. The piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform comprises a base, a stand column, a decoupling hook hinge, an X-axis bridge type amplification mechanism, an X-axis piezoelectric ceramic driver, an X-axis pre-tightening bolt, an X-axis hook hinge, a Y-axis bridge type amplification mechanism, a Y-axis piezoelectric ceramic driver, a Y-axis pre-tightening bolt, a Y-axis hook hinge and a working platform. The X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism are mounted on the outer sides of the two sides of the base. The vertex distances of the X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism and the base are equal, the X-axis piezoelectric ceramic driver is mounted in the X-axis bridge type amplification mechanism through the X-axis pre-tightening bolt, and the Y-axis piezoelectric ceramic driver is mounted in the Y-axis bridge type amplification mechanism through the Y-axis pre-tightening bolt. Each of the X-axis bridge type amplification mechanism and the Y-axis bridge type amplification mechanism comprises flexible hinge mechanisms symmetrically arranged on the two sides of the X-axis piezoelectric ceramic driver or the Y-axis piezoelectric ceramic driver and a beam for connecting the bridge type flexible hinge mechanisms. The X-axis bridge type amplification mechanism is connected with the working platform through the X-axis hook hinge, and the Y-axis bridge type amplification mechanism is connected with the working platform through the Y-axis hook hinge. By the adoption of the piezoelectric-driven two-degrees-of-freedom decoupling slight swing platform, the two-degrees-of-freedom decoupling precision slight swing can be achieved.

Owner:TIANJIN UNIV

Piston automatic measurement storage device

ActiveCN103604406BRealize transmissionQuality assuranceMeasurement devicesMeasurement precisionVertex distance

Owner:TONGXIANG HENGTAI PRECISION MACHINERY

Patient interactive fit tool and methodology for contact lens fitting

An interactive fit tool and methodology which may be utilized by an eye care professional to improve the efficiency and final outcome in selecting a pair of contact lenses targeted towards a specific patient visual need in the treatment of presbyopia. The interactive fit tool comprises an application which includes images that would allow a patient to decide if he or she desires balanced visual acuity, near biased visual acuity, or distance biased visual acuity. In addition, the interactive fit tool comprises fit guide tables and performs the calculations for vertex distance and spherical equivalent.

Owner:JOHNSON & JOHNSON VISION CARE INC

pxe piston automatic production line

ActiveCN103769823BGuaranteed machining accuracyReduce investmentProgramme-controlled manipulatorGripping headsMeasuring instrumentEngineering

The invention relates to the field of machining equipment, and particularly discloses an automatic PXE piston production line which is high in production efficiency and good in machining precision. The automatic PXE piston production line comprises machine tools and a gate-type transmission mechanism. A gate-type mechanical arm is arranged on the gate-type transmission mechanism, the two machine tools are arranged on the lower portion of the gate-type transmission mechanism at intervals, one end of the gate-type transmission mechanism is provided with a double-machine-material library, and the front faces of the machine tools are provided with multifunctional machine frames. Each multifunctional machine frame is provided with a single-machine-material library and a mechanical arm transmission mechanism, each mechanical transmission mechanism is provided with a PXE piston mechanical arm jig, and a main shaft inside each machine tool is provided with a PXE piston machining jig. According to the automatic PXE piston production line, pistons can be automatically fed, clamped and discharged through the mechanical arms, the automation effect is good, the machining efficiency can be improved, the investment on workers is reduced, production cost is lowered, and the machining precision of the pistons can be guaranteed through an automatic PXE piston measuring instrument which is used for measuring the ball vertex distance and the assembly of the pistons.

Owner:ZHEJIANG YIFENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com