Drag reduction method of thixotropic slurry

A thixotropic mud and slurry technology, which is used in pipeline laying and maintenance, pipe/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as large resistance of thixotropic mud, and achieve high drag reduction efficiency, reduced resistance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

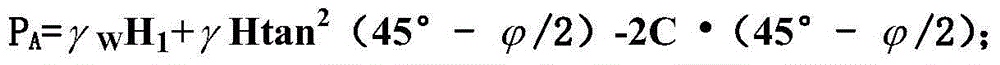

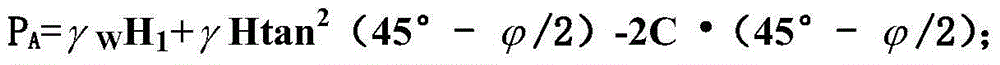

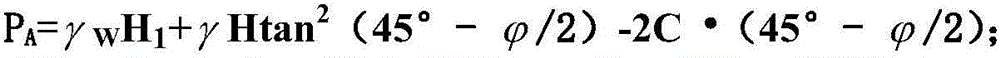

[0032] The invention provides a drag reduction method for thixotropic mud, the specific implementation steps of the method are as follows:

[0033] (1) Prepare thixotropic mud for drag reduction:

[0034] Thixotropic mud consists of sodium bentonite, carboxymethyl cellulose (CMC), sodium carbonate (Na 2 CO 3 ), clean water and an appropriate amount of admixture, the mass percent of each composition of the thixotropic mud is: sodium bentonite 10-20%, carboxymethyl cellulose 0.3-0.5%, sodium carbonate 0.2-0.4%, clean water and An appropriate amount of admixture is 80-90%; batching is carried out according to the composition mass percentage of the thixotropic mud, and then the stirred thixotropic mud is put into the slurry storage tank after stirring with a mixer for 12h-24h, so that the bentonite The particles fully absorb water and swell into a colloid; the main properties of the prepared thixotropic mud for drag reduction are: density 1.1-1.17g / cm 3 , viscosity 30-80s (meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com