Customized z-lens design program

a technology of z-lens and design program, applied in the field of customized z-lens design program, can solve the problems of many people experiencing distortion when looking off-center outside the central region, and problems such as vision problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

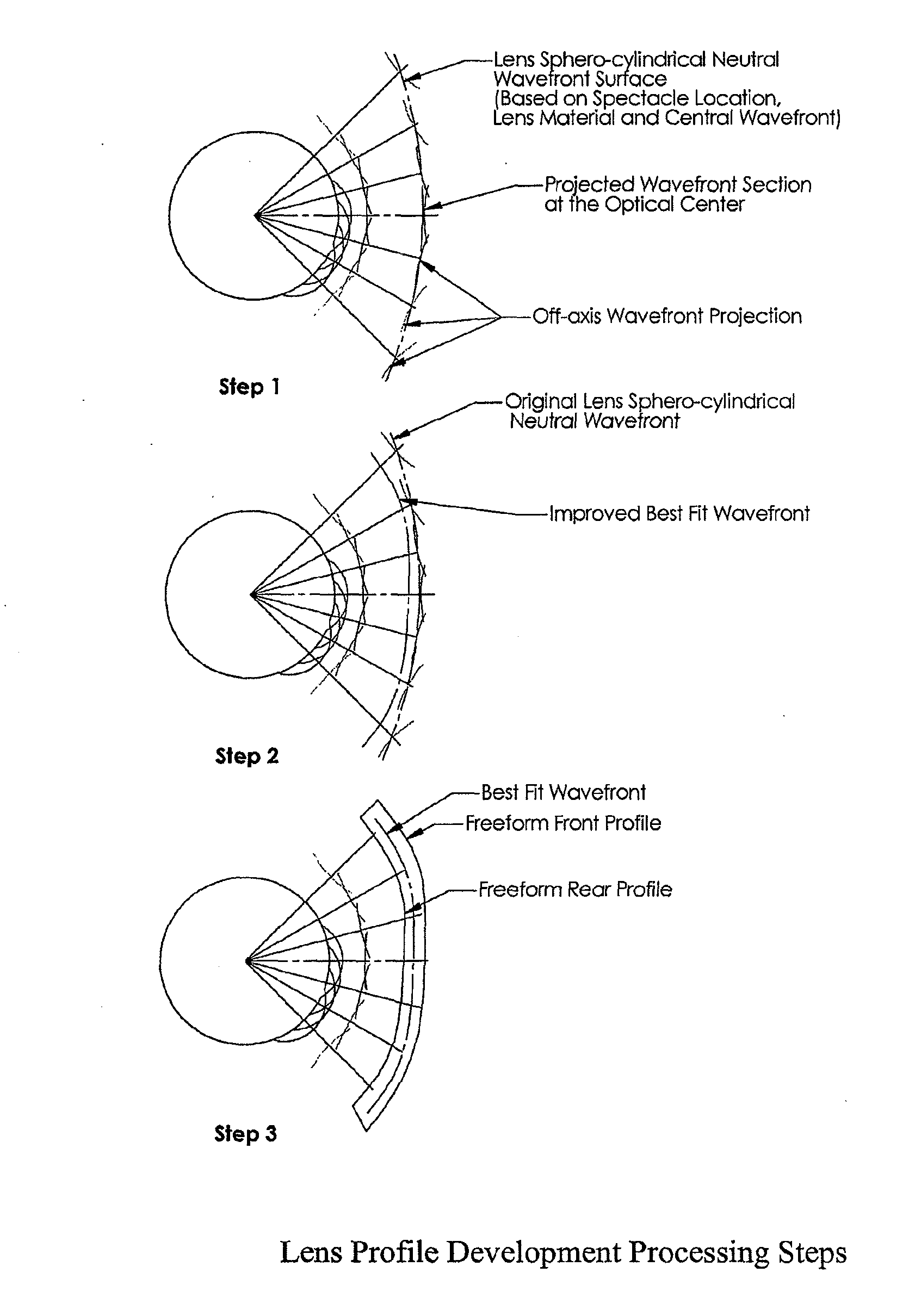

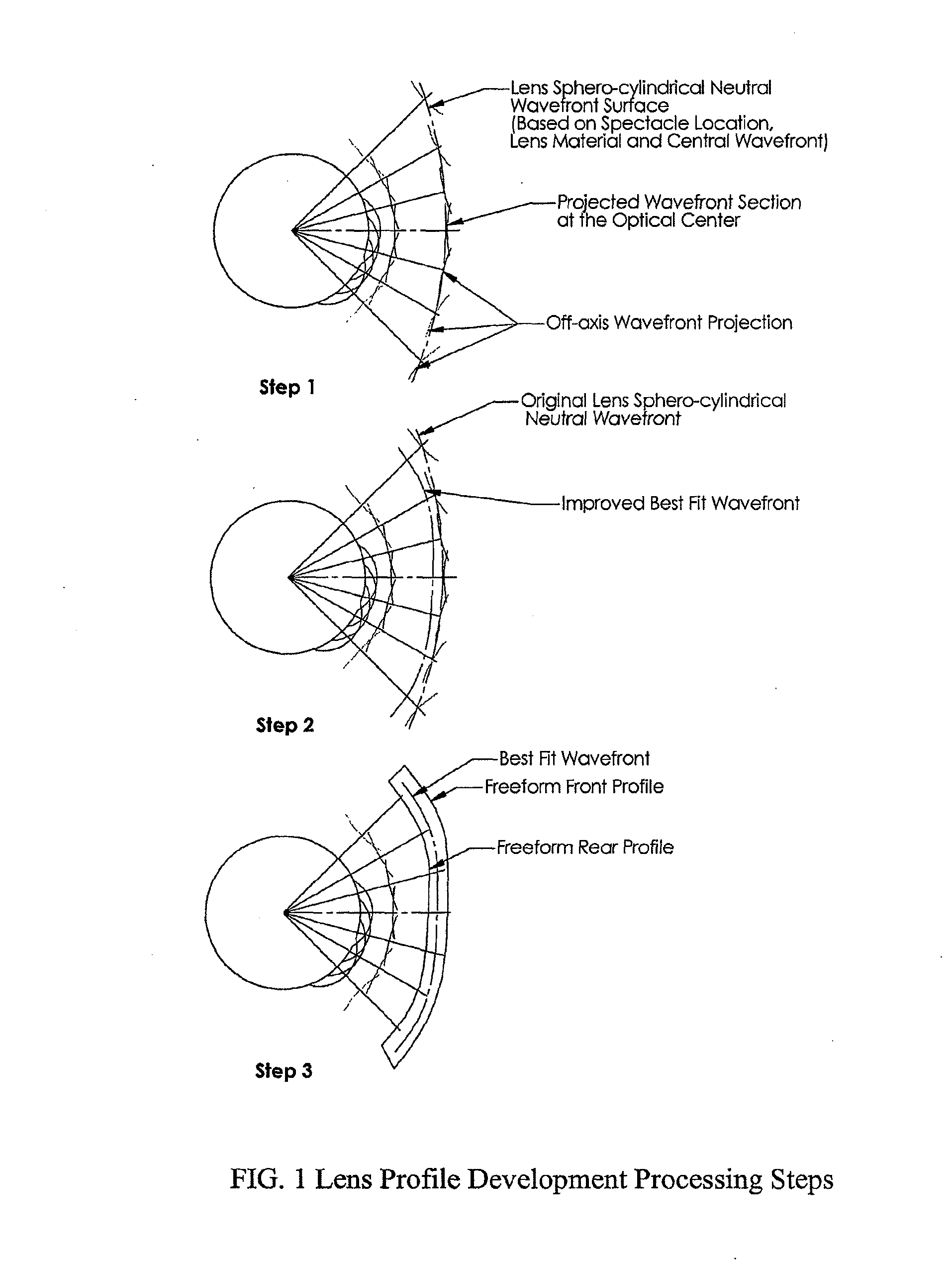

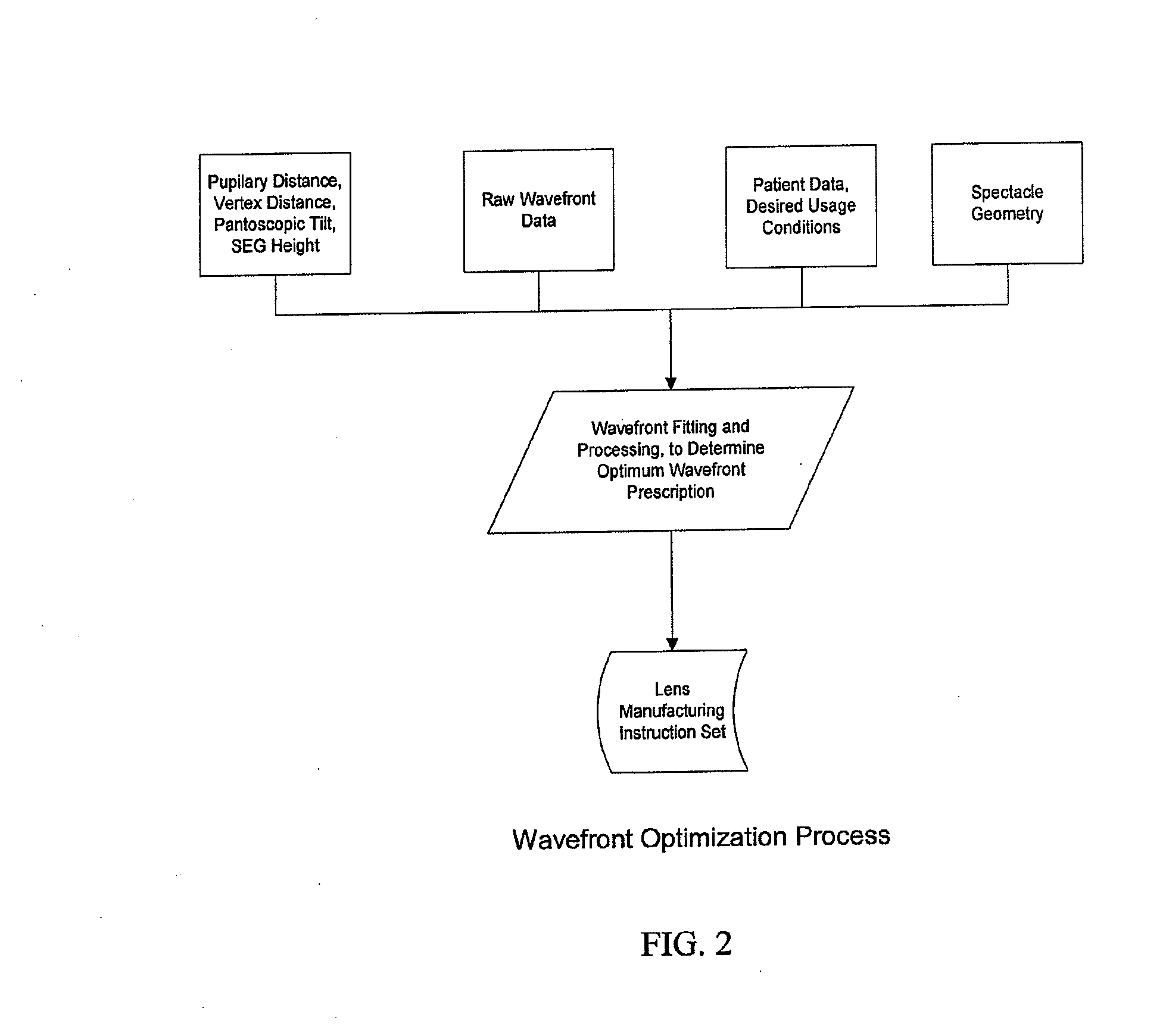

Image

Examples

example 1

Simple Alignment Tolerant Lens

[0057]For purposes of this example, lower case bold letters denote matrices (or equivalently, images), which describe either the two-dimensional (single-surface) lens as a optical-path delay (OPD) map, or a two-dimensional wavefront, also as an OPD map.[0058]ai,j Corrected wavefront aberration in the (i,j)th position.[0059]i, j Indices ith horizontal and jth vertical positions.[0060]n, m Indices of matrix elements.[0061]L Total number of pixels on side of (square) pupil and aberration matrices.[0062]N Total number of pixels on side of (square) spectacle OPD matrix.[0063]p, Pupil aberration OPD,[0064]pi,j pupil aberration in the (i,j)th position if it changes with gaze.[0065]s Spectacle OPD over entire range of lens, e.g. 50 mm diameter[0066]g Matrix describing weighting of error over pupil[0067]zk k-th (sampled) Zernike wavefront matrix[0068]w(i,j), Weighting over angle,[0069]wk(i,j) Weighting over angle for the kth Zernike term[0070]f Objective functio...

example 2

Simple Rotation and Alignment Tolerant Lens Design

[0090]This Example uses a method for optimizing the correction “programmed” onto a higher-order contact lens. Contact lenses can be designed to be in a certain orientation, but can still rotate with respect to this orientation and can slide as well so as to become decentralized. The unpredictable rotation and decentration of the lens during normal wearing can be addressed. Given a range of rotations and decentrations, the contact lens design is optimized to improve vision throughout the entire range by minimizing the total wavefront error summed over the ranges. The optimum over decentrations may be computed as in Equation (7) provided in Example 1. The optimum over rotations is computed as follows.

The error discriminant is:

f=∑θw(θ)∑n,m[p(n,m)+s(ncosθ+msinθ,-nsinθ+mcosθ)]2(9)

The optimal result is similar conceptually to the decentration case.

s=-1∑θw(θ){∑θw(θ)p(ncosθ-msinθ,nsinθ+mcosθ)}(10)

[0091]In a specific embodiment of the subject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com