Piston automatic measurement storage device

An automatic measurement and storage device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor measurement accuracy, affecting the processing quality of pistons, and slow measurement speed, so as to achieve the effects of quality assurance, accurate positioning, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

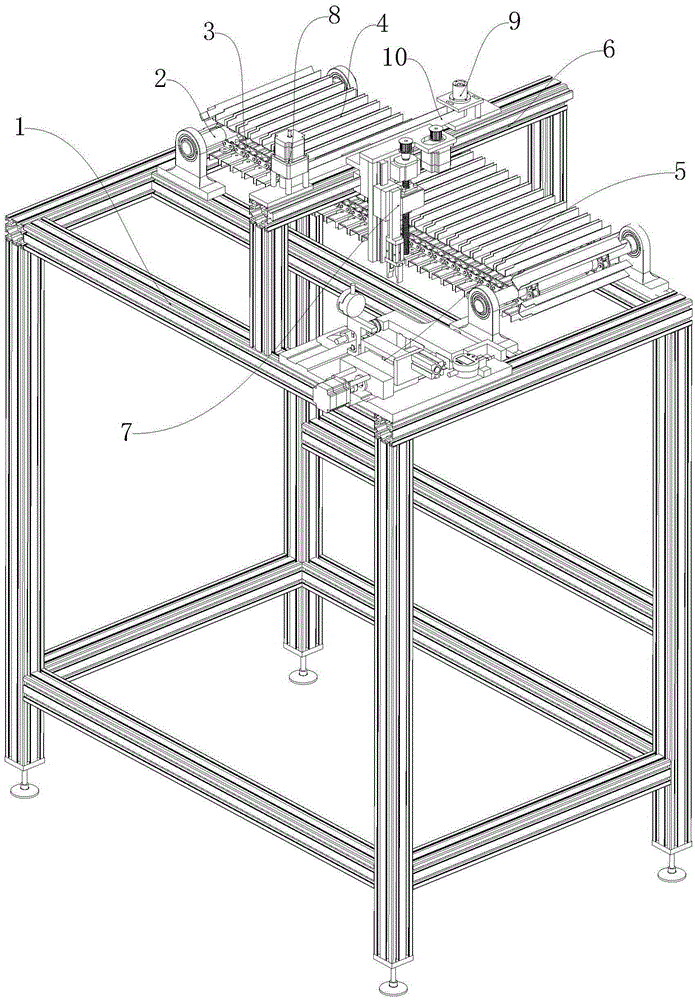

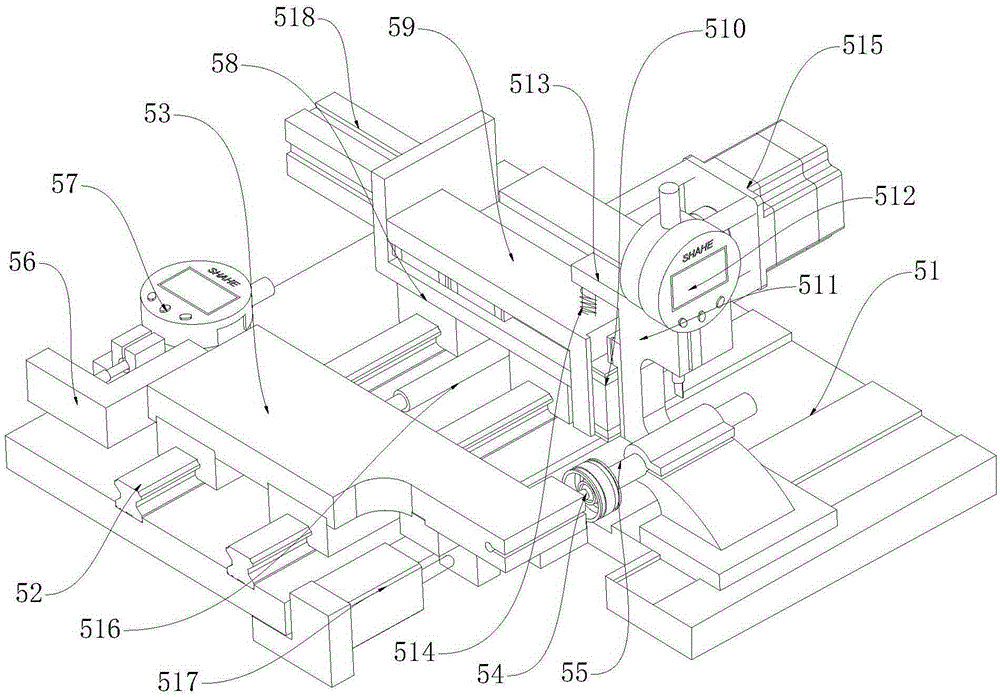

[0013] Such as figure 1 As shown, the piston automatic measurement and storage device described in this embodiment includes a detection frame 1, two rotating shafts 2 are provided at both ends of one side of the detection frame 1, and a circulating chain group 3 is matched on the rotating shaft 2 , Rectangular grooves 4 are arranged side by side on the circulating chain group 3, a detection mechanism 5 is provided at one end of the detection frame 1 on the side of the rectangular groove 4, and a horizontal slide rail 6 is provided above the detection frame 1. The slide rail 6 is provided with a vertically downward pneumatic gripper 7 which can move laterally, and the position of the pneumatic gripper 7 corresponds to the detection mechanism 5; figure 2 As shown, the structure of the detection mechanism 5 is: it includes a bottom plate 51, on which a double slide rail 52 is provided, the double slide rail 52 is parallel to the horizontal slide rail 6, and a measurement base is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com