Metallic cap closure having water repelling properties and method of fabricating the same

a technology of metal caps and water repellent properties, which is applied in the field of closures or caps, can solve the problems of rusting metallic caps, unsatisfactory customer satisfaction, and cap oxidation problems, and achieve the effect of eliminating the current corrosion problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

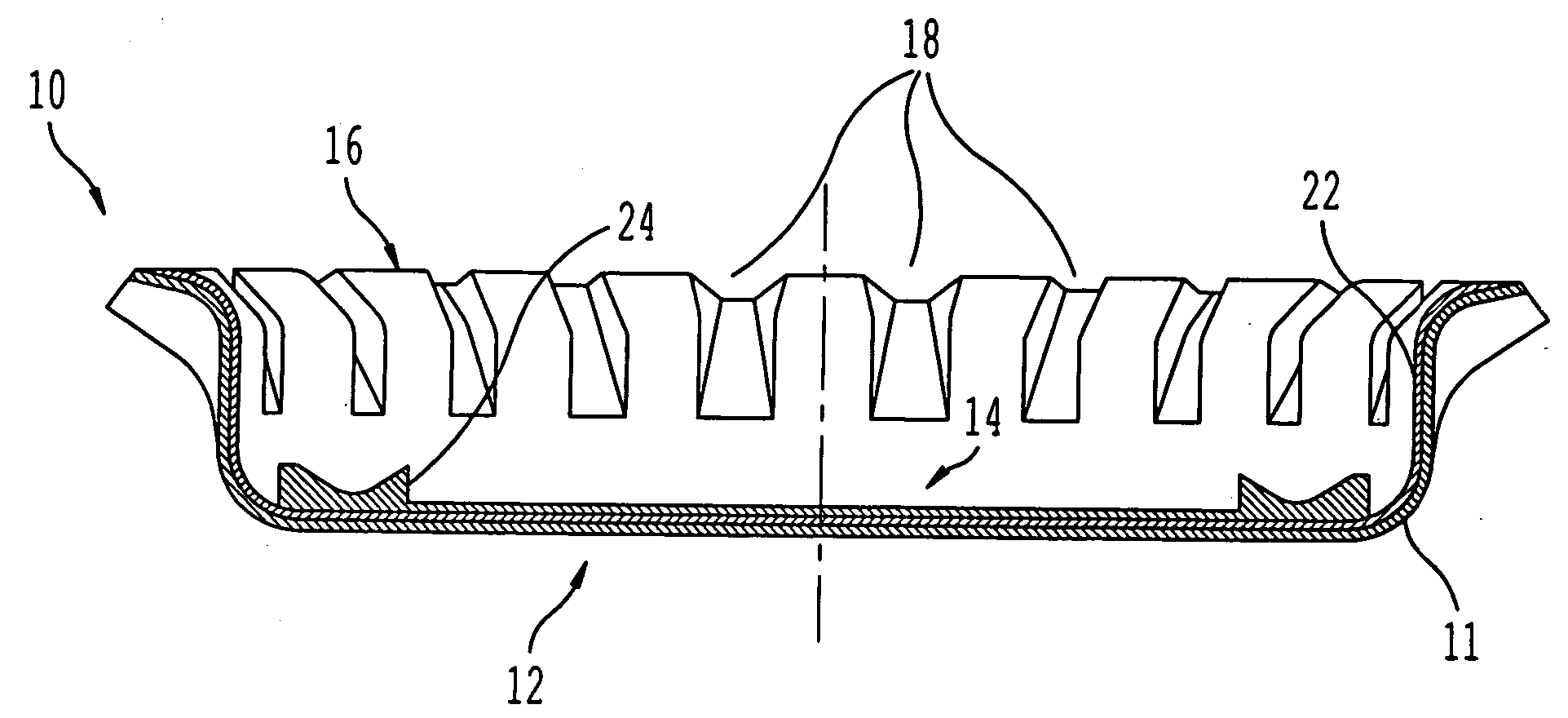

[0017]FIG. 1 illustrates a first embodiment of a metallic crown cap, or top, 10 having water repelling characteristics, the crown cap 10 comprising a metallic element 11 having a top portion 12, an under portion 14, and a corrugated skirt 16 with a plurality of skirt corrugations 18. Before labels and / or text is imprinted on the cap, a layer of a non-wetting primer material 22 is applied to the interior surface 14 of the metallic element 11, on top of which a subsequent liner 24 may also be applied. The general process after imprinting brand names or other indicia is to form the cap shell in punching presses. Then the liner, whatever its composition might be, is applied to the interior of the crown shell. In some cases a cure operation is necessary to get the correct adhesion of the liner to the crown shell. Although a crown cap having a liner has been illustrated, the present invention is equally applicable to a linerless crown cap.

[0018] In use, the metallic crown cap 10 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com