Preparation method of high heat-conducting diamond/copper-based composite material

A technology of copper-based composite materials and diamond, which is applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve the problem that the diamond coating cannot successfully adapt to the development of electronic packaging materials, etc., and achieve improved interface conditions , Improve the binding state, the effect of good interface binding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

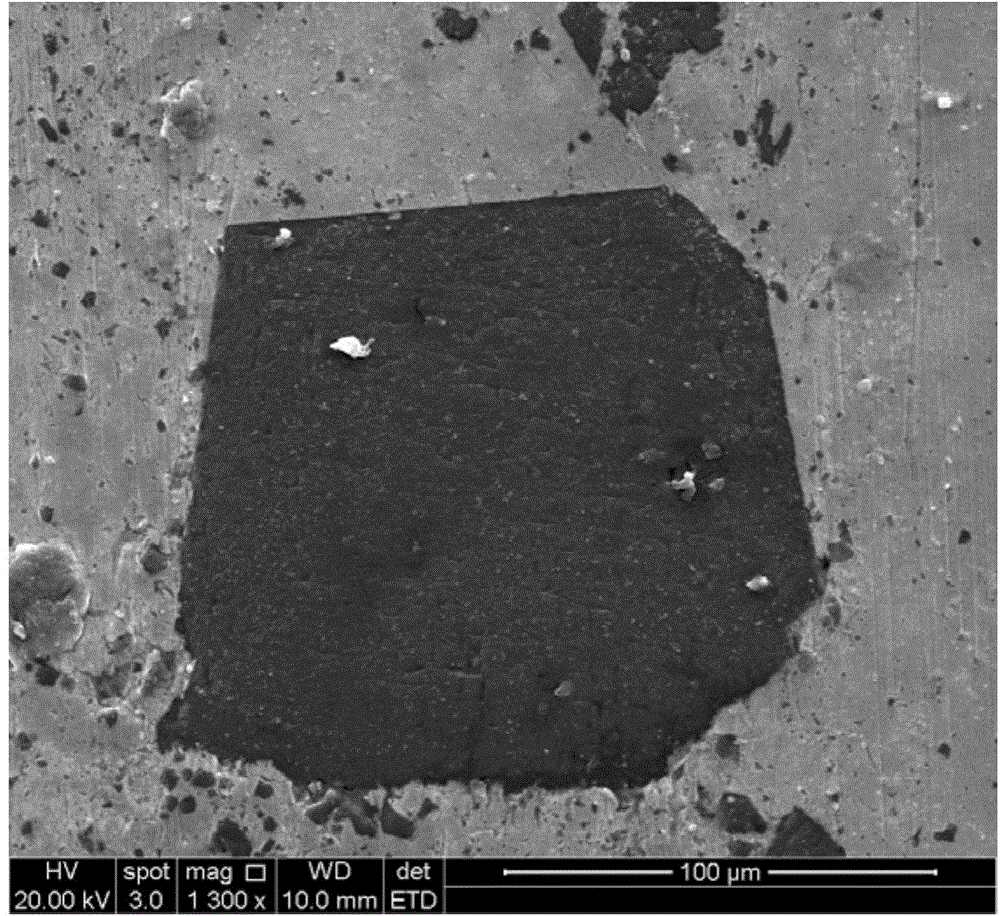

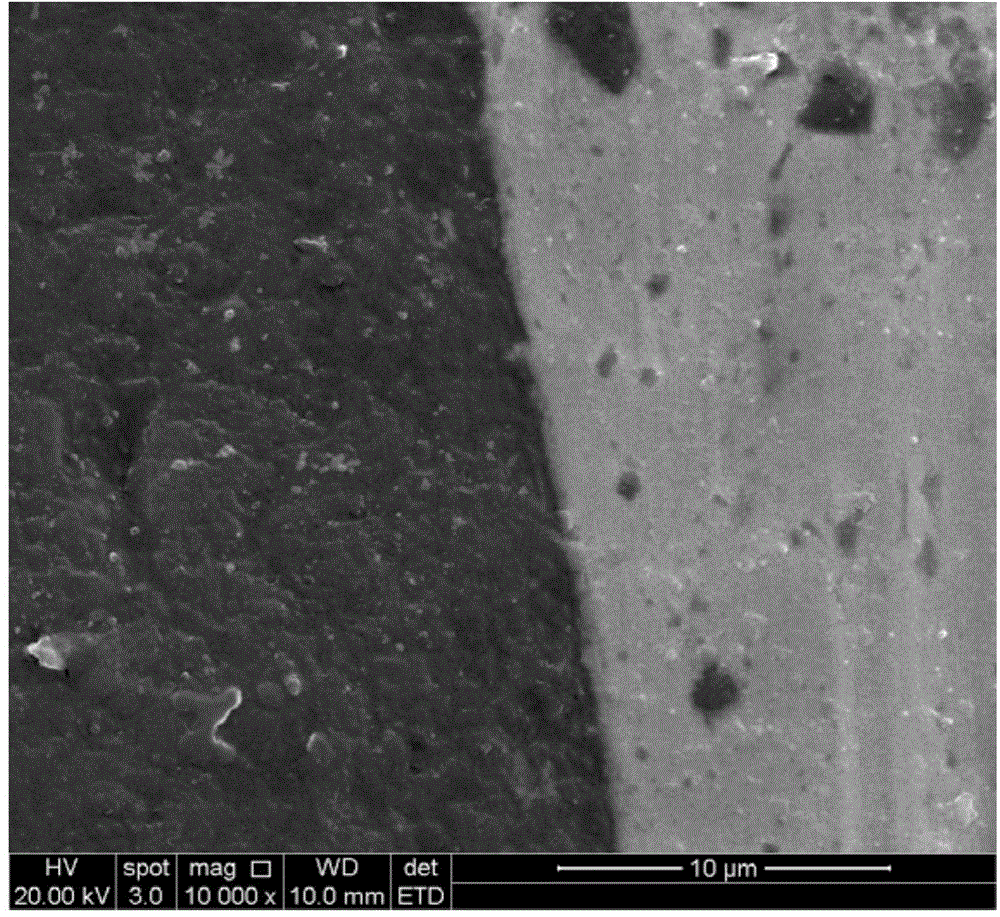

Image

Examples

Embodiment 1

[0022] 1. Use magnetron sputtering method to coat 0.5 μm molybdenum coating on the surface of diamond powder with a particle size of 100 μm to form molybdenum-coated diamond powder;

[0023] Two, adopt the method for electroless plating to plate the copper coating of 5 μm on the surface of the composite powder prepared in step 1 to form copper-plated molybdenum-plated diamond powder;

[0024] 3. The copper-plated molybdenum-plated diamond powder in step 2 is mixed with 10 μm copper powder, wherein the diamond volume fraction is 50%, forming a mixed powder;

[0025] 4. The mixed powder in step 3 is cold-pressed, and then the cold-pressed green body is put into a vacuum hot-press furnace for hot-press sintering. The sintering process is as follows: the degree of vacuum is 0.001-0.1Pa, the sintering temperature is 950°C, and the pressure is applied to 100MPa at the same time, and the heat preservation and pressure holding time is 2h, that is, the diamond / copper matrix composite m...

Embodiment 2

[0027] 1. Plating 0.1 μm molybdenum coating on the surface of diamond powder with a particle size of 100 μm by magnetron sputtering to form molybdenum-coated diamond powder;

[0028] Two, adopt the method for electroless plating to plate the copper coating of 4 μm on the surface of the composite powder prepared in step 1 to form copper-plated molybdenum-plated diamond powder;

[0029] 3. The copper-plated molybdenum-plated diamond powder in step 2 is mixed with 10 μm copper powder, wherein the diamond volume fraction is 40%, forming a mixed powder;

[0030] 4. The mixed powder in step 3 is cold-pressed, and then the cold-pressed green body is put into a vacuum hot-press furnace for hot-press sintering. The sintering process is as follows: the degree of vacuum is 0.001-0.1Pa, the sintering temperature is 950°C, and the pressure is applied to 100MPa at the same time, and the heat preservation and pressure holding time is 2h, that is, the diamond / copper matrix composite material ...

Embodiment 3

[0032] 1. Use magnetron sputtering method to coat 0.5 μm molybdenum coating on the surface of diamond powder with a particle size of 100 μm to form molybdenum-coated diamond powder;

[0033] Two, adopt the method for electroless plating to plate the copper coating of 4 μm on the surface of the composite powder prepared in step 1 to form copper-plated molybdenum-plated diamond powder;

[0034] 3. The copper-plated molybdenum-plated diamond powder in step 2 is mixed with 10 μm copper powder, wherein the diamond volume fraction is 30%, forming a mixed powder;

[0035] 4. The mixed powder in step 3 is cold-pressed, and then the cold-pressed green body is put into a vacuum hot-press furnace for hot-press sintering. The sintering process is as follows: the degree of vacuum is 0.001-0.1Pa, the sintering temperature is 950°C, and the pressure is applied to 100MPa at the same time, and the heat preservation and pressure holding time is 2h, that is, the diamond / copper matrix composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com