Microchannel heat exchanger system

A technology of microchannel heat exchanger and heat exchange system, applied in the field of microchannel heat exchanger system of non-wetting multiphase flow, can solve the problems of restricted use area, complex heat exchange system, difficult separation and recovery of multiphase fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

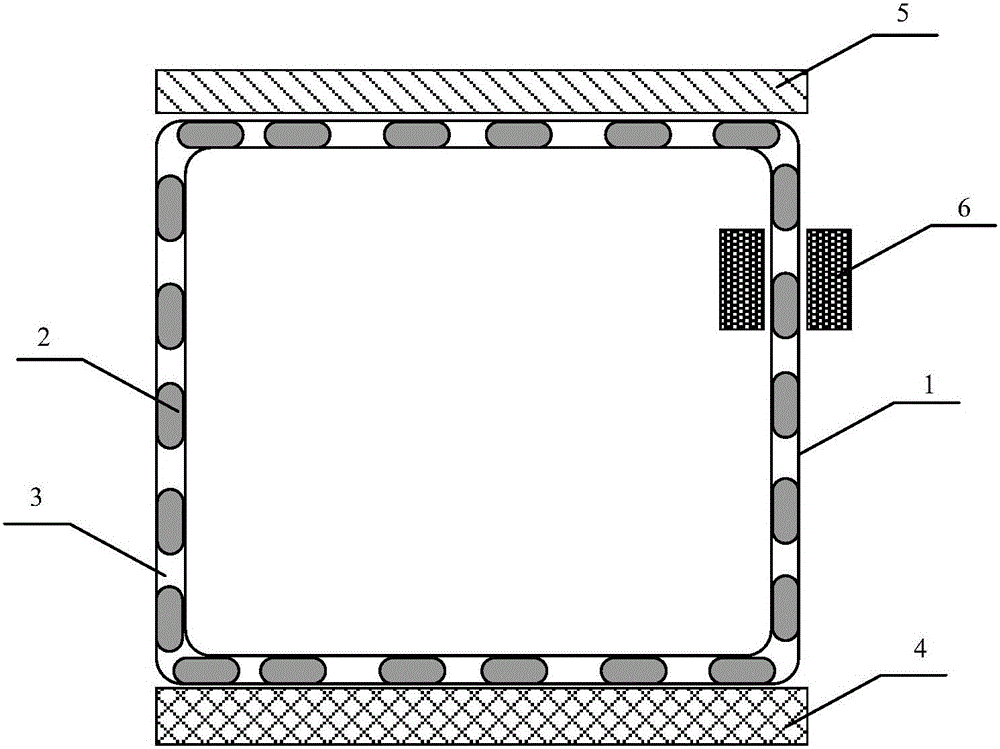

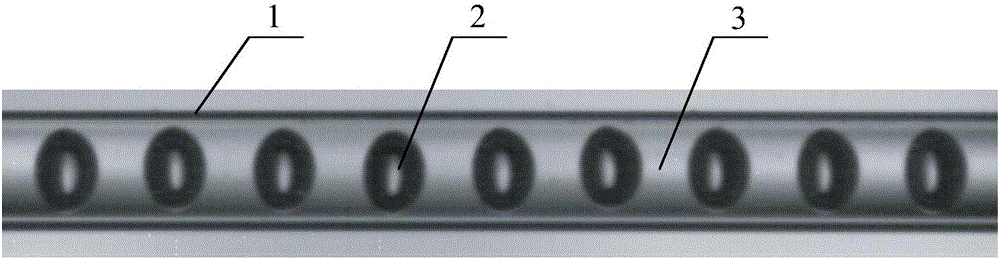

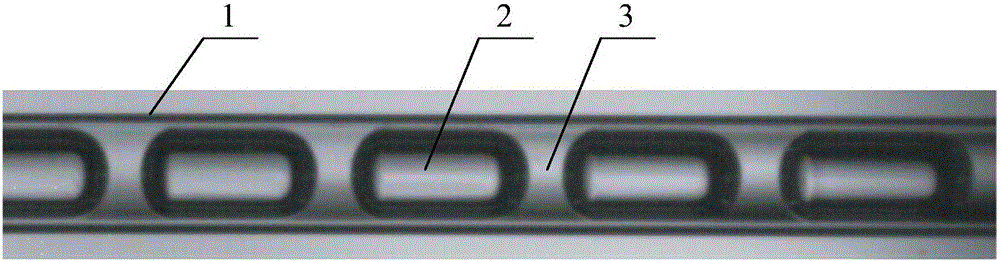

[0028] See attached figure 1 , a microchannel heat exchanger system of this embodiment, including a closed flow channel 1, the flow channel 1 is set between the cold source 5 and the heat source 4 for heat transfer, the flow channel 1 can use copper tubes, aluminum tubes , quartz tube, etc., can also be formed by etching on the silicon base; the flow channel 1 is sealed with two-phase fluid or multi-phase fluid, and the multi-phase fluid is non-wetting, which can be gas, liquid or liquid according to actual needs Metals; non-wetting multiphase fluids with flow regimes of bubbly or slug flow. When only one phase of the multiphase fluid is in dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com