Microscopic rock network model manufacturing method

A technology of network model and production method, which is applied in earth-moving drilling, wellbore/well components, etc., can solve problems such as differences in oil and gas flow states, failure to observe fluid flow in observation channels, adsorption, diffusion, and large size differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

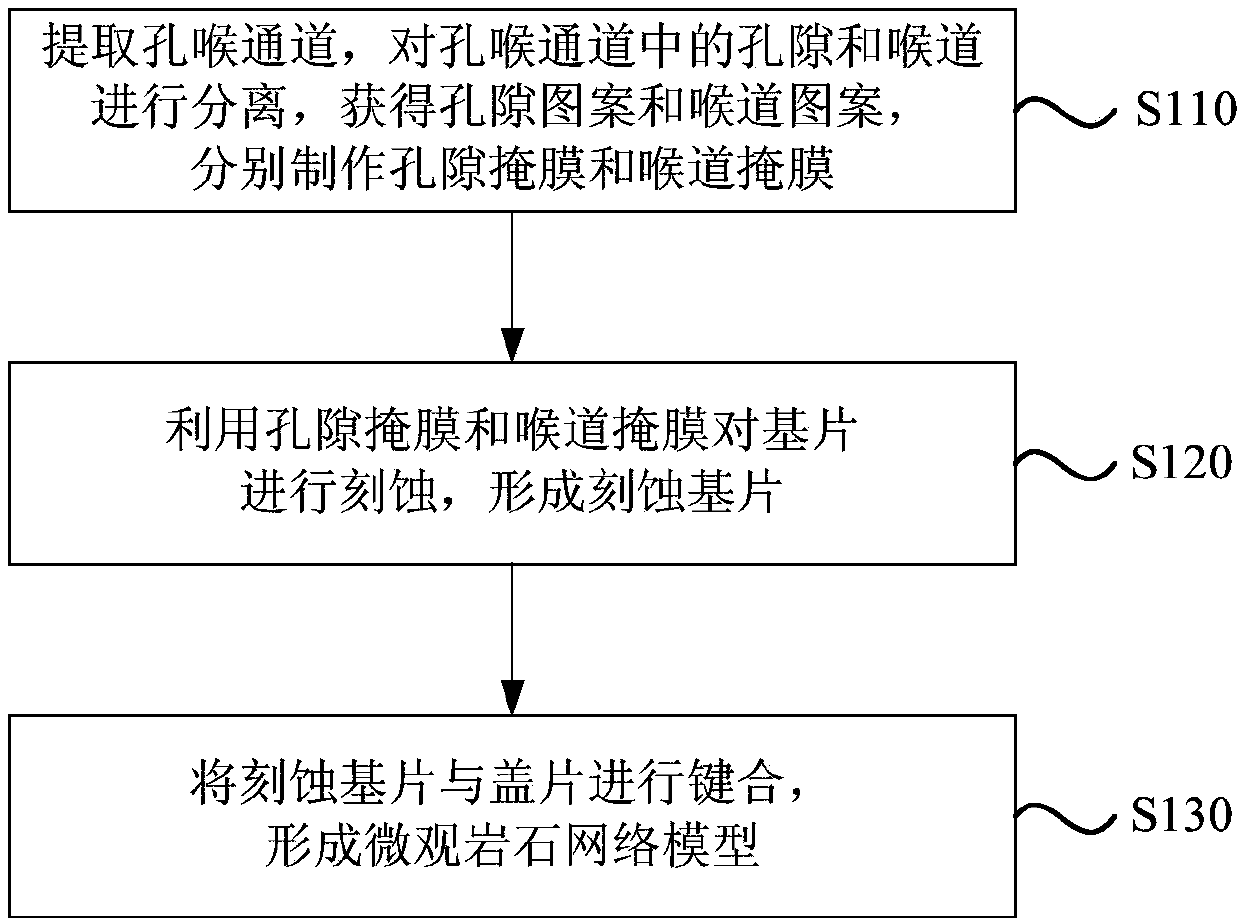

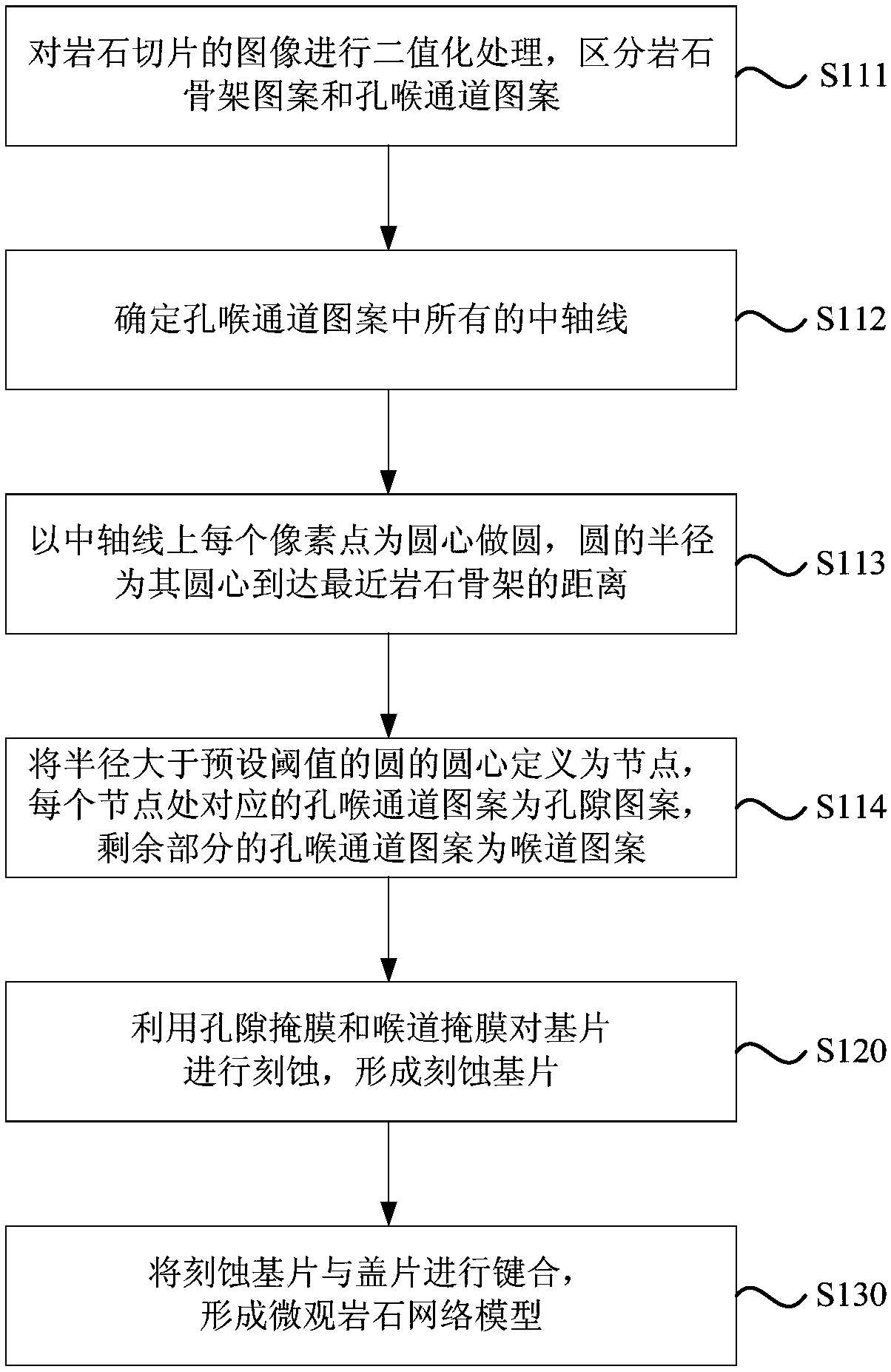

[0058] figure 1It is a flowchart of a method for making a microscopic rock network model provided by Embodiment 1 of the present invention. This embodiment is applicable to the production of a microscopic model of tight oil reservoirs, and specifically includes the following steps:

[0059] Step 110, extracting pore-throat channels, separating pores and throats in the pore-throat channels, obtaining pore patterns and throat patterns, and making pore masks and throat masks respectively.

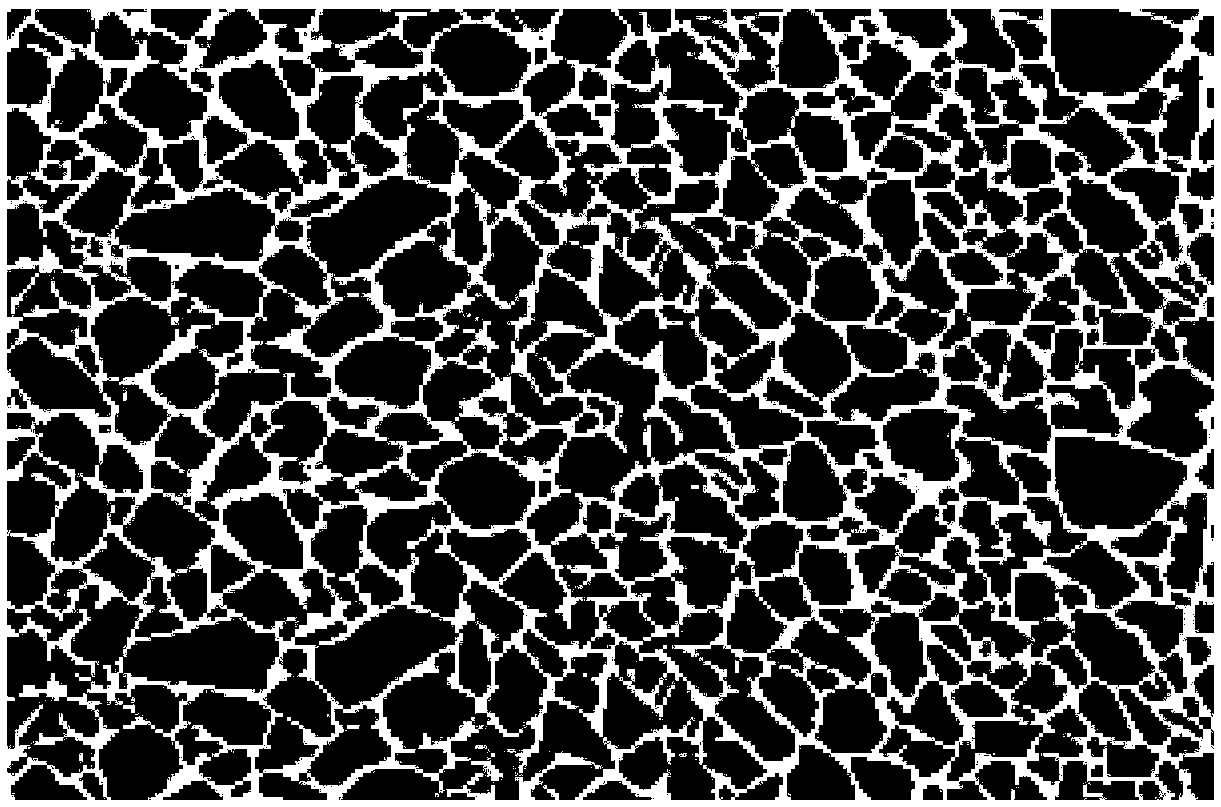

[0060] Among them, the extraction of pore-throat channels can be realized by using real sandstone castings, and thin slices of real sandstone castings are cut to form rock slices, and the rock skeleton area in the rock slice image is distinguished by binarizing the images of the rock slices and the pore-throat channel area, realize the extraction of pore-throat channels, and obtain the pattern composed of the pore area. In the pore-throat channel area, the area where the pore pattern is remove...

Embodiment 2

[0077] Figure 8 It is a flow chart of another method for making a microscopic rock network model provided in Embodiment 2 of the present invention, refer to Figure 8 , in the manufacturing method provided in this embodiment, S120, etching the substrate using the pore mask and the throat mask, specifically includes the following steps:

[0078] S121, pore etching, using a pore mask to etch the substrate to form a half-etched substrate;

[0079] Wherein, both the pore etching in this step and the throat etching in step S123 can be performed using a wet etching process, and a half-etched substrate with pores can be obtained through pore etching.

[0080] Preferably, the method of pore etching includes: stacking the pore mask and the substrate and exposing through an exposure machine, so that the pattern of the pore mask is transferred to the substrate; cleaning the photoresist on the substrate and exposing part; in an ultrasonic water bath environment, the substrate is immers...

Embodiment 3

[0096] Figure 10 It is a flow chart of another method for making a microscopic rock network model provided by Embodiment 3 of the present invention. refer to Figure 10 , in the manufacturing method provided in this embodiment, S130, bonding the etched substrate and the cover sheet to form a microscopic rock network model, specifically includes the following steps:

[0097] S131. Pretreating the etched substrate;

[0098] Among them, the pretreatment of the etched substrate includes boiling treatment and rinsing, first with H 2 SO 4 with H 2 o 2 Prepare the solution according to the ratio of 4:1 and boil the etched substrate and cover slip for 10-15 minutes, then rinse with petroleum ether and ethanol for 10 minutes to clean the etched substrate and cover slip, and petroleum ether can wash off the etched substrate and cover slip. Ethanol is used to wash away the inorganic substances adhering to the etched substrate and cover slip. Through the pretreatment of the etched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com