Spray coating capable of preventing slag adhesion

An anti-sticking slag coating and coating technology, applied in the field of refractory materials, can solve problems such as reducing the service life of refractory materials and equipment, accidental damage to refractory materials, and affecting normal production, so as to improve service life, prevent erosion, and facilitate slag removal Effect

Inactive Publication Date: 2016-03-02

上海柯瑞冶金炉料有限公司

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

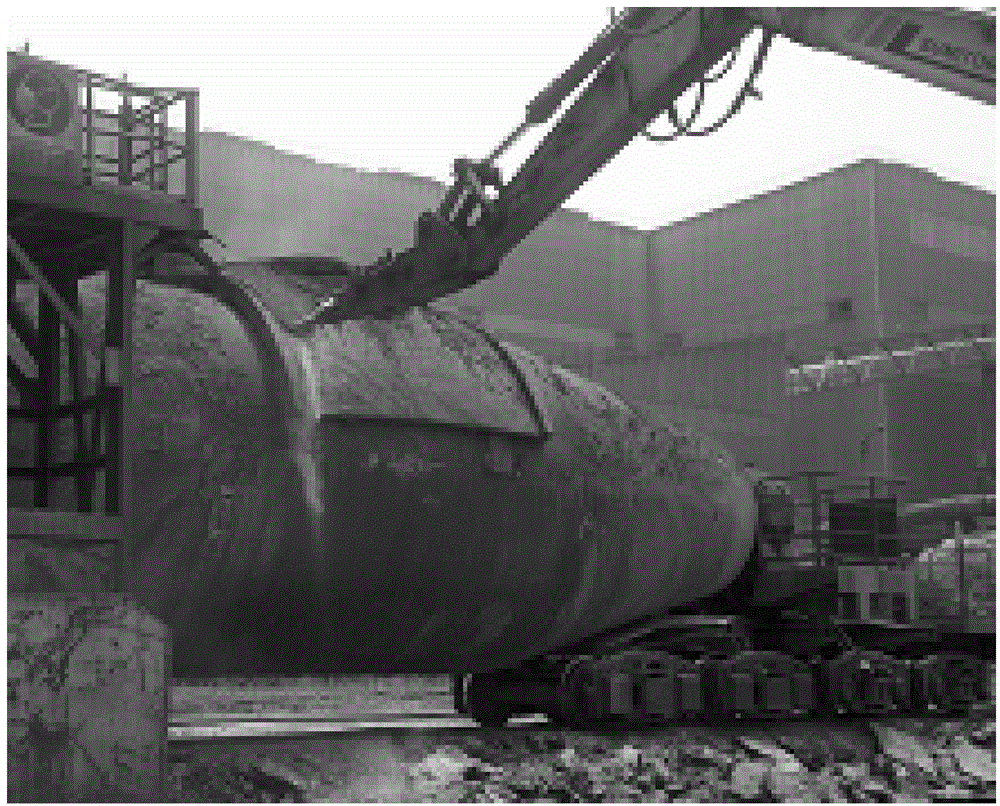

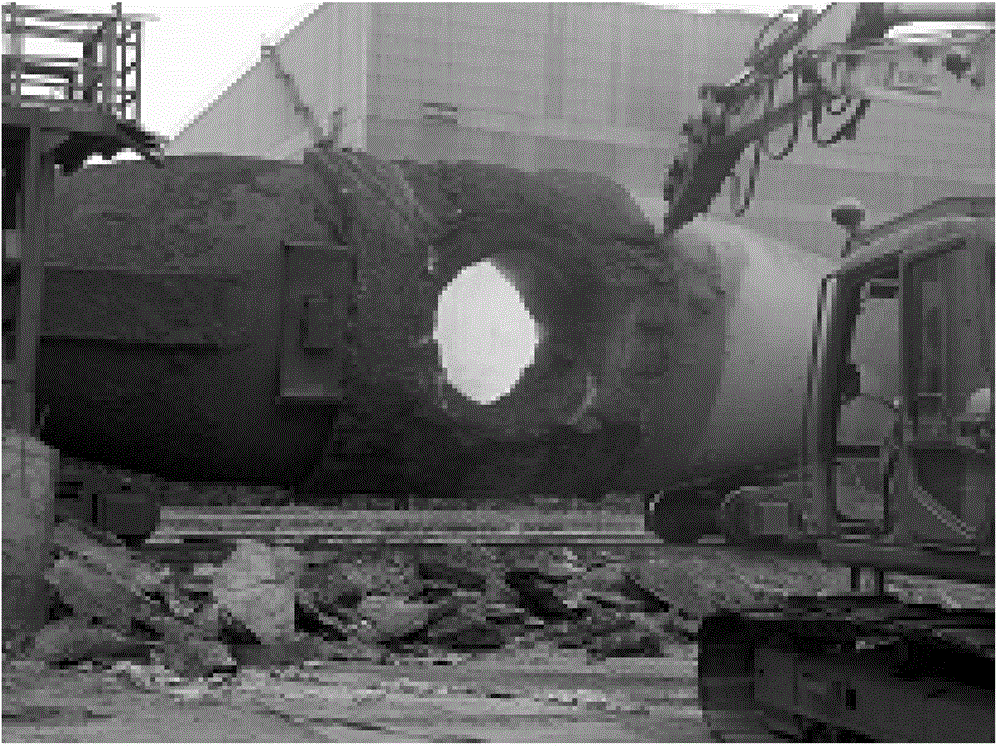

[0002] Thermal equipment in the iron and steel industry, such as the furnace mouth of the converter, the ladle mouth, the ladle mouth of the molten iron, and the iron ladle of the mixed iron car, etc., are often damaged due to serious slag sticking and difficult slag removal, which affects the operating rate and has high labor intensity, which is greatly reduced. The service life of refractory materials and equipment; it will also cause the equipment to be overweight due to sticky slag, which will affect the normal production or even stop production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0041] The anti-year slag spray coating provided by the invention consists of:

[0042] MgO

Embodiment 2

[0044] The paint composition offered is:

[0045] MgO

Embodiment 3

[0047] The paint composition offered is:

[0048] MgO

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a coating capable of preventing slag adhesion. The coating is characterized by being prepared from, by mass, 8-15 parts of MgO, 15-25 parts of Al2O3, 12-20 parts of SiC, 20-30 parts of SiO2, 2-6 parts of Si, 10-20 parts of C and 0.5-2 parts of Fe2O3, and the coating is prepared by additionally adding 22%-28% of water and conducting stirring through an emulsifying machine. According to the coating capable of preventing the slag adhesion, waste materials of the fire-resistant material industry and the solar energy industry are fully utilized to serve as the main raw materials, and the slag adhesion is prevented by utilizing the non-wetting property of carbon, silicon carbide and the like in the waste raw materials to slags; reactions that metallic silicon is reacted with oxygen to form silicon dioxide, and then the silicon dioxide is reacted with magnesium oxide to form forsterite or reacted with aluminum oxide to form mullite are utilized, and looseness of the materials is caused along with volume expansion, so that the materials are automatically disengaged or easily removed. The coating is used for Baosteel torpedo iron mixing vehicles, Baosteel hot metal ladles, VD shielding caps of the Shanghai steel fifth-factory and LAST immersion covers of the Shanghai steel first factory to enable the service life of fire-resistant materials to be prolonged; the service life is prolonged by 50 percent or above except the hot metal ladles.

Description

technical field [0001] The invention relates to an anti-sticking slag spray coating, which belongs to the field of refractory materials. Background technique [0002] Thermal equipment in the iron and steel industry, such as the furnace mouth of the converter, the ladle mouth, the molten iron ladle mouth, and the iron ladle of the mixed iron car, are often due to serious slag sticking and difficult slag removal, resulting in accidental damage to the refractory material, affecting the operating rate and high labor intensity, which is greatly reduced. The service life of refractory materials and equipment will also be overweight due to sticky slag, which will affect the normal production or even stop production. There are also many studies on anti-sticking slag at home and abroad: Mittal uses active lime, corundum slag, and fluorite to make magnesia refractory materials, which have high refractoriness, good resistance to steel slag erosion, and ladle anti-sticking for purifyin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66

Inventor 蓝振华吴朝齐顾燕赵玲娣

Owner 上海柯瑞冶金炉料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com