Reprocessing method of phosphate ore flotation tailings and phosphate ore flotation method

A technology for flotation tailings and reprocessing, applied in flotation, solid separation, magnesium chloride, etc., can solve the problem of low utilization rate of phosphate ore flotation tailings resources, improve resource utilization rate, and solve the problem of land occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

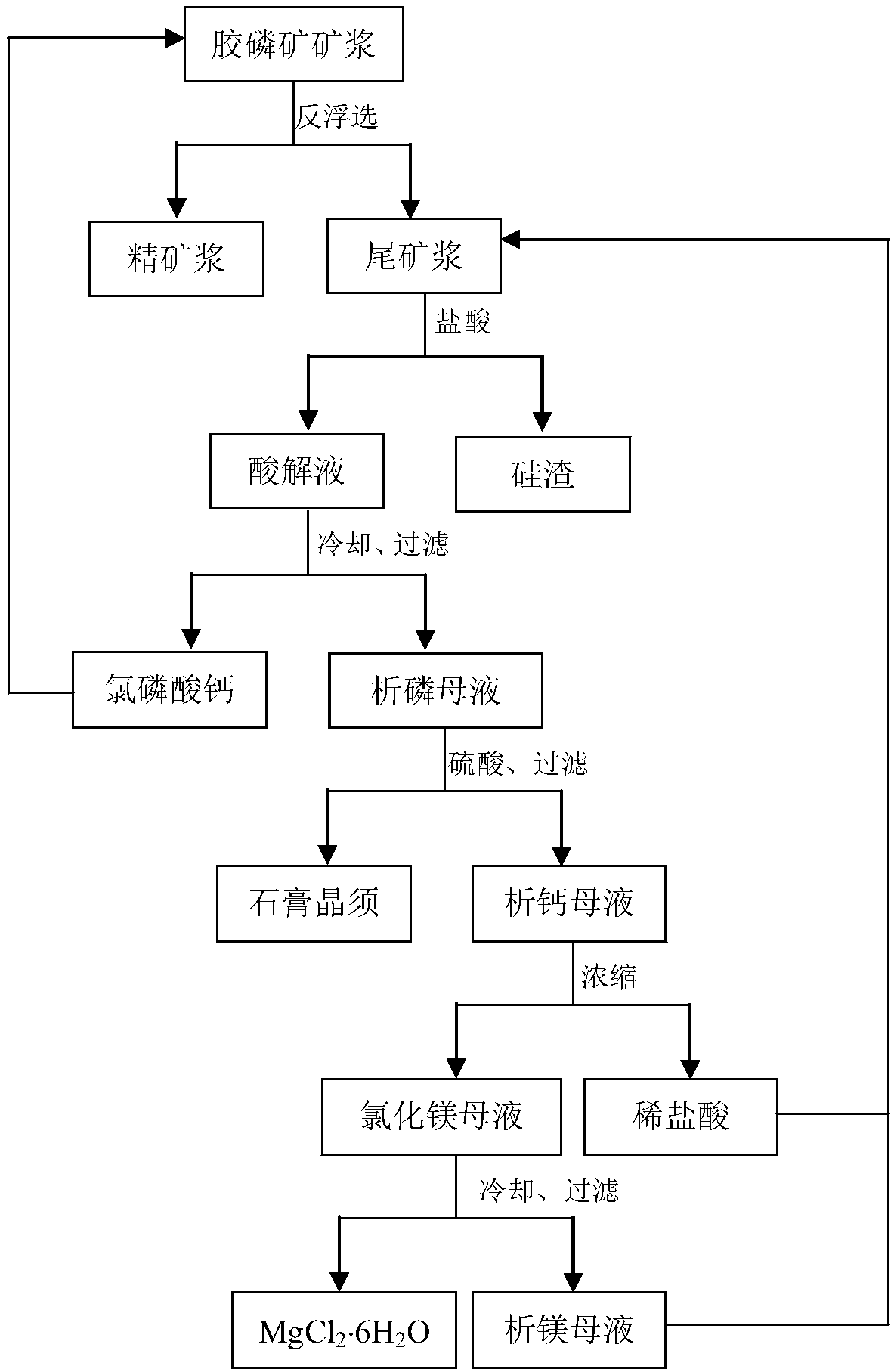

[0039] combine figure 1 Shown, a kind of reprocessing method of phosphate rock flotation tailings, comprises the following steps:

[0040] 1) adding hydrochloric acid to the slurry of phosphate ore flotation tailings, reacting, filtering to obtain silicon slag and acid solution;

[0041] 2) cooling and filtering the acid solution to obtain calcium chlorophosphate and phosphorus analysis mother liquor;

[0042] 3) heating the phosphorus-analyzing mother liquor, stirring and adding sulfuric acid, reacting, and filtering to obtain gypsum whiskers and calcium-analyzing mother liquor;

[0043] 4) concentrating the calcium analysis mother liquor to obtain dilute hydrochloric acid and magnesium chloride mother liquor;

[0044] 5) the magnesium chloride mother liquor is cooled, filters to obtain MgCl 2 ·6H 2 O and magnesium analysis mother liquor.

[0045] The reprocessing method of phosphate rock flotation tailings in this embodiment firstly acidifies the phosphate rock flotatio...

Embodiment 2

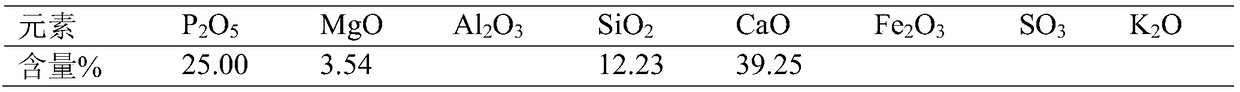

[0054] The collophanite of Hubei Ezhong Ecological Engineering Co., Ltd. was used as the raw ore, and the chemical composition of the main elements of the collophanite is shown in Table 1.

[0055] Table 1 (%)

[0056]

[0057] combine figure 1 As shown, adopt the reprocessing method of the phosphate rock flotation tailings of embodiment 1 to reprocess the tailings slurry that this collophosite flotation process produces, specifically comprise the following steps:

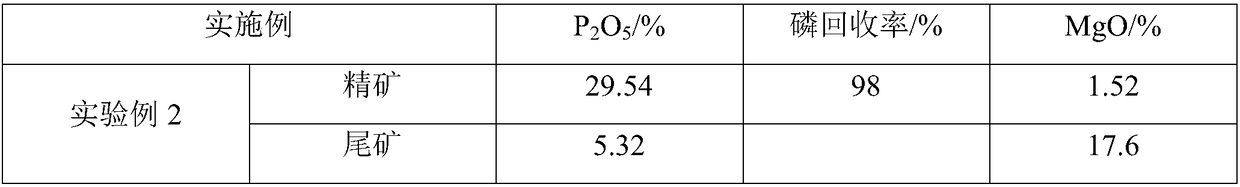

[0058] 1) Use a rod mill to dissociate 166 kg of the above-mentioned collianophosphate ore to make a pulp with a concentration of 30%, add the calcium chloride phosphate product in step 5) to the pulp, and add sulfuric acid to the pulp to adjust the pH When the value reaches 4-5, stir for 2 minutes, then add phosphoric acid inhibitor according to the amount of 5kg / t raw ore, stir for 2 minutes, then add hydroxysulfostearate saponin phosphate rock collector according to the amount of 1.2kg / t raw ore , aeration,...

Embodiment 3

[0075] The collophanite of Hubei Ezhong Ecological Engineering Co., Ltd. was used as the raw ore, and the chemical composition of the main elements of the collophanite is shown in Table 1.

[0076] combine figure 1 As shown, adopt the reprocessing method of the phosphate rock flotation tailings of embodiment 1 to reprocess the tailings slurry that this collophosite flotation process produces, specifically comprise the following steps:

[0077] 1) Use a rod mill to dissociate 166 kg of the above-mentioned collianophosphate ore to make a pulp with a concentration of 30%, add the calcium chloride phosphate product in step 5) to the pulp, and add sulfuric acid to the pulp to adjust the pH When the value reaches 4~5, stir for 2 minutes, then add phosphoric acid inhibitor according to the amount of 5kg / t raw ore, stir for 2 minutes, then add hydroxysulfostearate saponin phosphate rock collector according to the amount of 1.3kg / t raw ore , aeration, and reverse flotation to obtain c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com