Method for removing boron and iron from boron containing magnesium chloride saturated liquid

A magnesium chloride and boron removal technology, applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of large dissolution loss, high boron extraction efficiency, low recovery rate, etc., and achieve the effect of solving large dissolution loss, short process flow and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

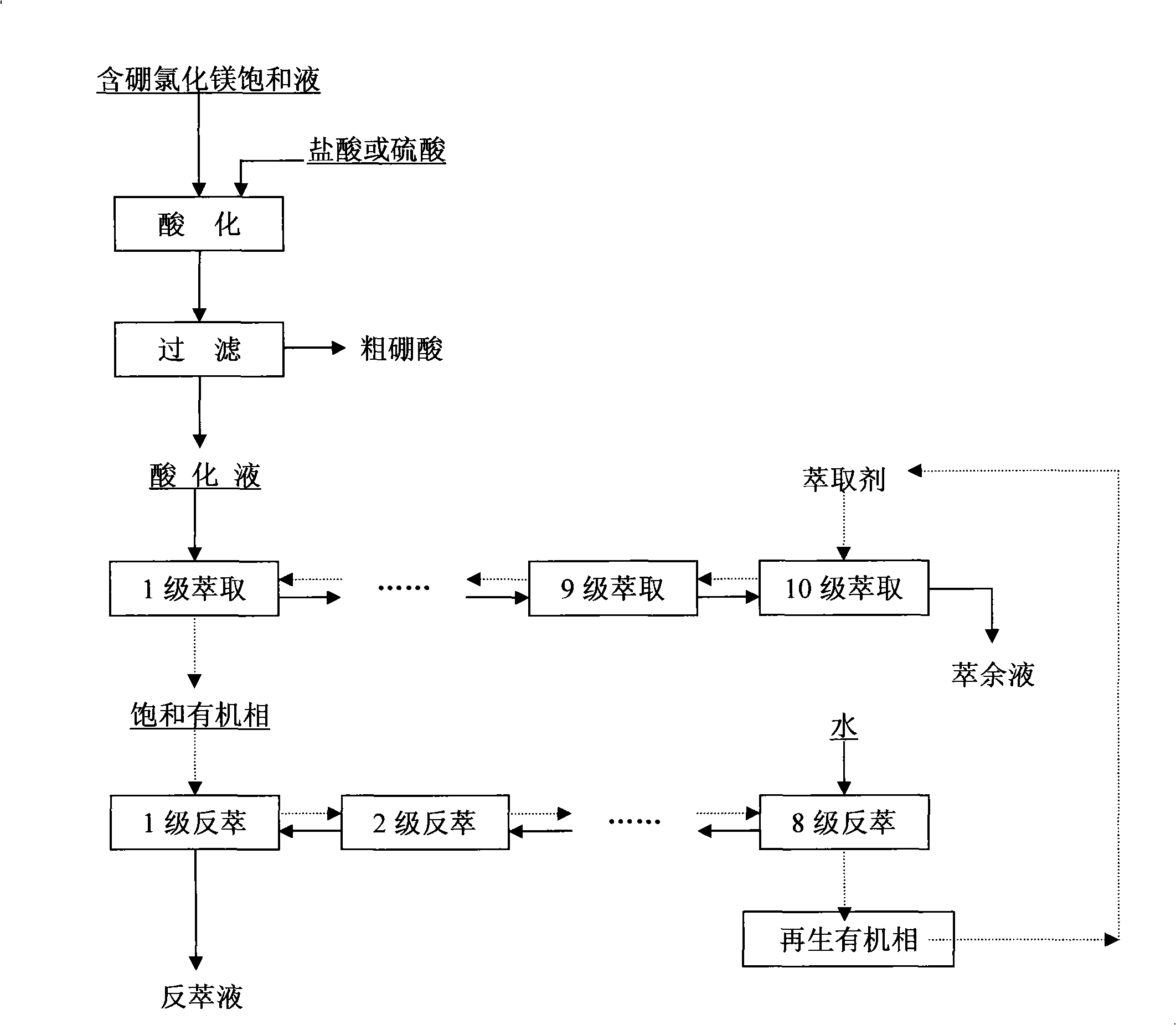

Method used

Image

Examples

Embodiment 1

[0009] A method for removing boron and iron from a boron-containing magnesium chloride saturated liquid, adding sulfuric acid to the boron-containing magnesium chloride saturated liquid, adjusting the pH value of the slurry to 1, stirring and reacting at room temperature for 30 minutes, filtering the slurry to obtain crude boric acid and acidizing liquid, Crude boric acid is refined to obtain boric acid, and acidification solution (B 2 o 3 7.5g / l, Fe 2 o 3 130 mg / l) 400 ml, add 600 ml of extraction agent and mix, place in a 1500 ml separatory funnel and shake for 20 minutes after mixing, separate phases after standing, phase separation time is 1 minute, carry out 10-stage countercurrent extraction, and finally obtain saturated organic Phase and raffinate, the raffinate is low boron and low iron magnesium chloride saturated liquid, in the raffinate B 2 o 3 Content below 25mg / l, Fe 2 o 3 22mg / l, boron recovery rate > 99%, the saturated solution is used to prepare high-puri...

Embodiment 2

[0011] A method for removing boron and iron from boron-containing magnesium chloride saturated liquid, adding sulfuric acid to the boron-containing magnesium chloride saturated liquid, adjusting the pH value of the slurry to 3, stirring and reacting at room temperature for 60 minutes, filtering the slurry to obtain crude boric acid and acidizing liquid, Crude boric acid is refined to obtain boric acid, and acidification solution (B 2 o 3 7.5g / l, Fe 2 o 3 130 mg / l) 400 ml, add 400 ml of extractant and mix, place in a 1000 ml separatory funnel after mixing and shake for 3 minutes, separate the phases after standing for 20 minutes, carry out 7-stage countercurrent extraction, and finally obtain saturated organic Phase and raffinate, the raffinate is low boron and low iron magnesium chloride saturated liquid, in the raffinate B 2 o 3 Content below 20mg / l, Fe 2 o 3 20mg / l, boron recovery rate > 99%, the saturated solution is used to prepare high-purity magnesium salt, 400 ml ...

Embodiment 3

[0013] A method for removing boron and iron from boron-containing magnesium chloride saturated liquid, adding sulfuric acid to the boron-containing magnesium chloride saturated liquid, adjusting the pH value of the slurry to 2, stirring and reacting at room temperature for 45 minutes, filtering the slurry to obtain crude boric acid and acidizing liquid, Crude boric acid is refined to obtain boric acid, and acidification solution (B 2 o 3 7.5g / l, Fe 2 o 3 130 mg / l) 400 ml, add 400 ml of extractant and mix, place in a 1000 ml separatory funnel after mixing and shake for 15 minutes, separate phases after standing, phase separation time is 15 minutes, carry out 8-stage countercurrent extraction, and finally obtain saturated organic Phase and raffinate, the raffinate is low boron and low iron magnesium chloride saturated liquid, in the raffinate B 2 o 3 Content below 23mg / l, Fe 2 o 3 24mg / l, boron recovery rate > 99%, the saturated solution is used to prepare high-purity magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com