Method for preparing calcium sulfate whiskers and magnesium hydroxide by decomposing phosphate tailings through hydrochloric acid

A calcium sulfate whisker and magnesium hydroxide technology, applied in the direction of magnesium hydroxide, magnesium chloride, magnesium halide, etc., can solve the problems of low quality, overcapacity, and restriction of compound fertilizer production capacity, and achieve simple production process, low production cost, The effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

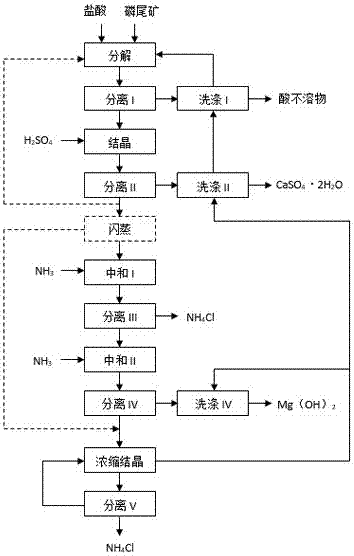

Method used

Image

Examples

Embodiment 1

[0029] Add phosphorus tailings and hydrochloric acid (mother liquor) to the decomposition tank, control the amount of HCl in the leaching tank to be 2.0 times that of CaO and MgO in the input phosphorus tailings, the reaction temperature is 40°C, and the reaction time is 30 minutes. The reaction slurry is subjected to solid-liquid separation I to generate the first mother liquor containing calcium chloride and magnesium chloride, and the solid waste residue obtained after the first filter cake washing I is an acid insoluble matter.

[0030] Add sulfuric acid reaction crystallization to the first mother liquor containing calcium chloride and magnesium chloride, according to the total amount of Ca2+ in the mother liquor, the amount of sulfuric acid is 1.0 times of the Ca2+ content in the filtrate, and the liquid-solid ratio is controlled at 10:1 in the calcium sulfate crystallization process. And control the reaction temperature to 50° C. and the reaction time to 30 minutes to ob...

Embodiment 2

[0039] Add phosphorus tailings and hydrochloric acid (mother liquor) to the decomposition tank, control the amount of HCl in the leaching tank to be 2.5 times that of CaO and MgO in the input phosphorus tailings, the reaction temperature is 30°C, and the reaction time is 60 minutes. The reaction slurry is subjected to solid-liquid separation I to generate the first mother liquor containing calcium chloride and magnesium chloride, and the solid waste residue obtained after washing the first filter cake is an acid insoluble matter.

[0040] Add sulfuric acid reaction crystallization to the first mother liquor containing calcium chloride and magnesium chloride, according to the total amount of Ca2+ in the mother liquor, the amount of sulfuric acid is 1.0 times of the Ca2+ content in the filtrate, and the liquid-solid ratio is controlled at 20:1 in the calcium sulfate crystallization process. The reaction temperature was controlled at 40° C., and the reaction time was 60 minutes to...

Embodiment 3

[0049] Add phosphorus tailings and hydrochloric acid (mother liquor) to the decomposition tank, control the amount of HCl in the leaching tank to be 2.2 times that of CaO and MgO in the input phosphorus tailings, the reaction temperature is 40°C, and the reaction time is 60 minutes. The reaction slurry is subjected to solid-liquid separation I to generate the first mother liquor containing calcium chloride and magnesium chloride, and the solid waste residue obtained after the first filter cake washing I is an acid insoluble matter.

[0050] Add sulfuric acid reaction crystallization to the first mother liquor containing calcium chloride and magnesium chloride, according to the total amount of Ca2+ in the mother liquor, the amount of sulfuric acid is 1.0 times of the Ca2+ content in the filtrate, and the liquid-solid ratio is controlled at 8:1 during the calcium sulfate crystallization process. And control the reaction temperature to 50° C. and the reaction time to 60 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com