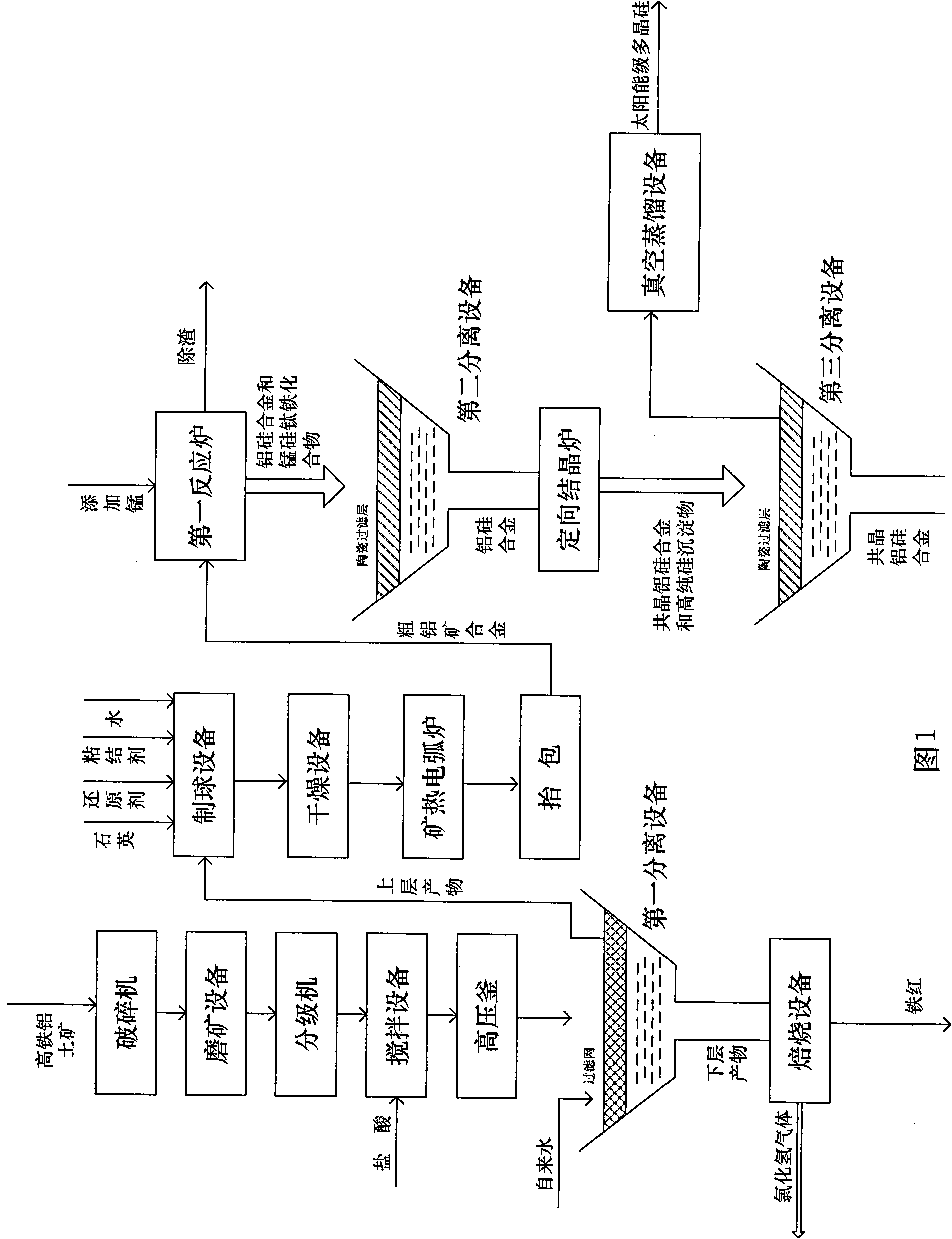

Combination production method for obtaining multi-products using high iron bauxite as raw material

A high-iron bauxite and production method technology, applied in chemical instruments and methods, iron oxide, iron halide, etc., can solve the problems of high energy consumption, high cost of aluminum-silicon alloy, long production process, etc., and achieve economic benefits Good, low cost, high added value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] The first step: material preparation

[0113] Use a crusher to crush the high-iron bauxite to a particle size of 0.1-25 mm to obtain crushed materials;

[0114] Grinding the pulverized material with ore grinding equipment to obtain ground powder;

[0115] Use a classifier to select the grinding powder material with a particle size of 50-150 μm to obtain high-iron bauxite fine powder;

[0116] In the present invention, the grinding powder material not selected by the classifier can continue to be ground by grinding equipment;

[0117] The present inventor analyzes the composition of the high-iron bauxite mining in the Aksu area of Xinjiang and obtains: iron oxide Fe 2 o 3 20wt%, iron silicate FeSiO 3 5wt%, aluminum oxide Al 2 o 3 58wt%, silicon oxide SiO 2 It is 6wt%, and the balance is other impurities. Impurities are generally carbonate minerals (such as magnesium carbonate, calcium carbonate and dolomite), silicate minerals.

[0118] The second step: prepar...

Embodiment 2

[0156] The first step: material preparation

[0157] Use a crusher to crush the high-iron bauxite to a particle size of 0.1-25 mm to obtain crushed materials;

[0158] Grinding the pulverized material with ore grinding equipment to obtain ground powder;

[0159] Use a classifier to select the grinding powder material with a particle size of 50-150 μm to obtain high-iron bauxite fine powder;

[0160] In the present invention, the grinding powder material not selected by the classifier can continue to be ground by grinding equipment;

[0161] The composition of high iron bauxite is: iron oxide Fe 2 o 3 15wt%, iron silicate FeSiO 3 10wt%, alumina Al 2 o 3 60wt%, silicon oxide SiO 2 It is 3wt%, and the balance is other impurities. Impurities are generally carbonate minerals (such as magnesium carbonate, calcium carbonate and dolomite), silicate minerals.

[0162] The second step: preparation of extract

[0163] (A) Putting the high iron bauxite fine powder and the hydroc...

Embodiment 3

[0199] The first step: material preparation

[0200] Use a crusher to crush the high-iron bauxite to a particle size of 0.1-25 mm to obtain crushed materials;

[0201] Grinding the pulverized material with ore grinding equipment to obtain ground powder;

[0202] Use a classifier to select the grinding powder material with a particle size of 50-150 μm to obtain high-iron bauxite fine powder;

[0203] In the present invention, the grinding powder material not selected by the classifier can continue to be ground by grinding equipment;

[0204] The composition of high iron bauxite is: iron oxide Fe 2 o3 17wt%, iron silicate FeSiO 3 5wt%, aluminum oxide Al 2 o 3 60wt%, silicon oxide SiO 2 It is 8wt%, and the balance is other impurities. Impurities are generally carbonate minerals (such as magnesium carbonate, calcium carbonate and dolomite), silicate minerals.

[0205] The second step: preparation of extract

[0206] (A) put the high-iron bauxite fine powder and the hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com