Methodf or preparing anhydrous magnesium chloride

A technology of anhydrous magnesium chloride and hydrated magnesium chloride, applied in the direction of preparation/separation of magnesium chloride, magnesium halide, ammonia, etc., can solve the problems of insufficient precipitation rate, large demand for ammonia and organic solvents, etc. The effect of high utilization rate and high precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

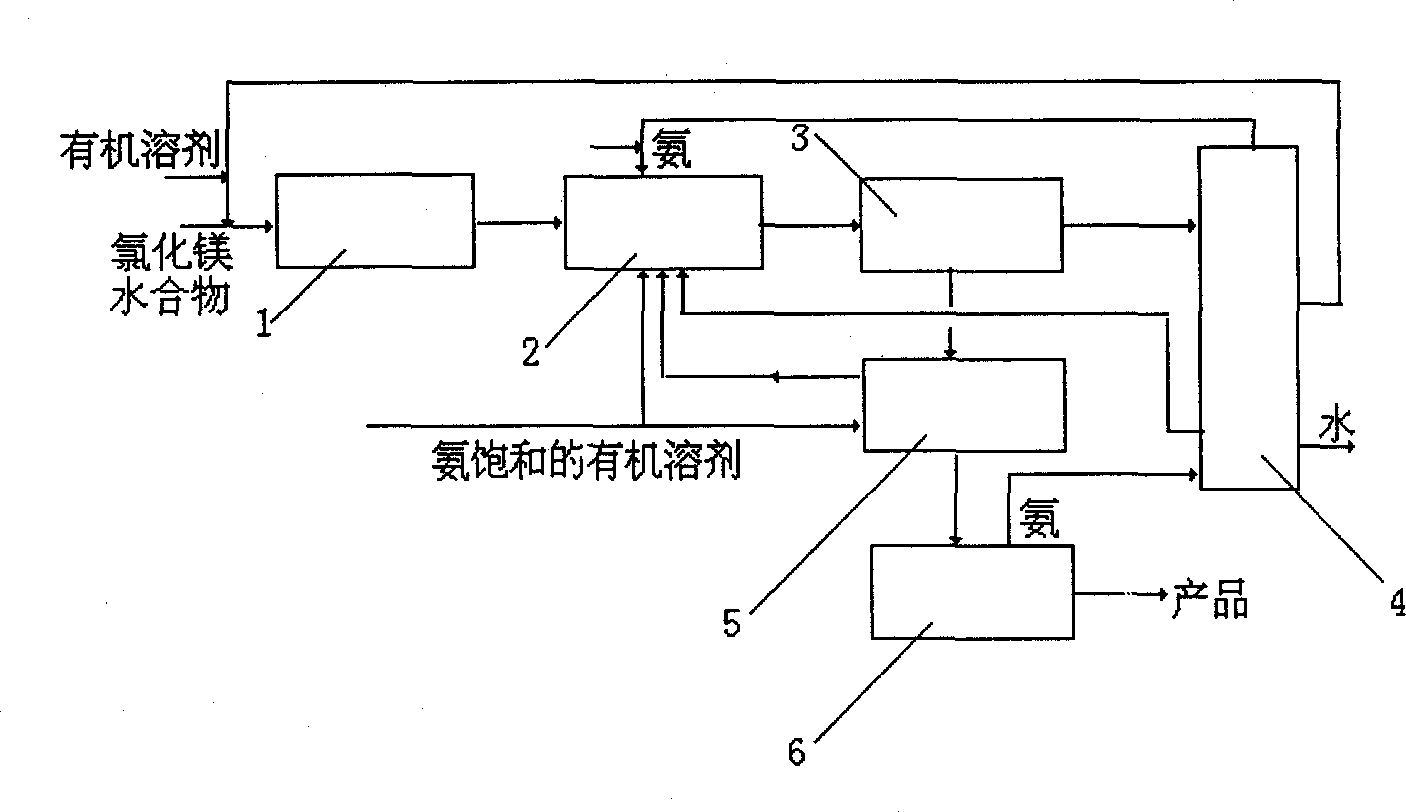

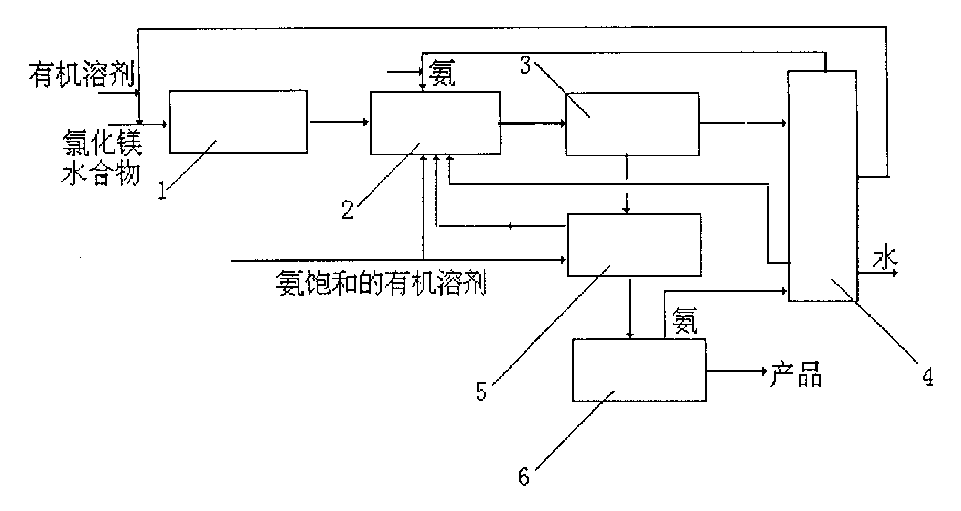

Image

Examples

Embodiment 1

[0035] In a 1-liter reactor, add 250 grams of methanol, 50 grams of ethanol and 3 grams of ammonium chloride. Under normal temperature and stirring conditions, feed ammonia to make it saturated in the solvent, and slowly add 300 grams of magnesium chloride solution that has been prepared. gram, wherein containing magnesium chloride 9.3%, water 10.7%, ammonium chloride 1.2%, organic solvent 78.8%: After reacting for 1.5 hours, the slurry feed liquid was filtered, and the mixed solution of 100 gram methanol and 20 gram ethanol was saturated with ammonia Washing, the solid product is calcined at 550 DEG C for 1.2 hours through isolating the air, and anhydrous magnesium chloride can be obtained, wherein the moisture content is less than 0.1%, the magnesium oxide content is less than 0.1%, and the productive rate of magnesium chloride is 89.3%, producing 1 mole of magnesium chloride in production The ammonia requirement is 15 moles.

Embodiment 2

[0037] In the reactor of 1 liter, add 300 grams of embodiment 1 washing solution, other is the same as embodiment 1, through the anhydrous magnesium chloride of crystallization, deamination, its water content is 0.1%, and magnesium oxide content is 0.1%, the magnesium chloride The yield was 98.6%. The consumption of ammonia and organic solvent reduces 40.4% and 35.8% respectively than embodiment 1. Example 3

Embodiment 3

[0038] In a 1-liter reactor, add 300 grams of low-boiling point alcohol, including 87% methanol, 10% ethanol, 3% butanol and 3 grams of ammonium chloride. Saturation, while slowly adding 300 grams of magnesium chloride solution prepared, which contains 9.6% magnesium chloride, 14.6% water, 1.5% ammonium chloride, 74.3% low-boiling point alcohol, wherein 87% methanol, 10% ethanol and 3% butanol; After reacting for 1.5 hours, the slurry feed liquid was filtered, washed with 100 grams of ammonia-saturated low-boiling alcohol, wherein 87% of methyl alcohol, 10% of ethanol and 3% of butanol, and the solid product was calcined at 450° C. for 1.5 hours through isolated air, Anhydrous magnesium chloride can be obtained, wherein the water content is less than 0.3%, the magnesium oxide content is less than 0.2%, the yield of magnesium chloride is 90.2%, and the ammonia demand for producing 1 mole of magnesium chloride is 18 moles. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com