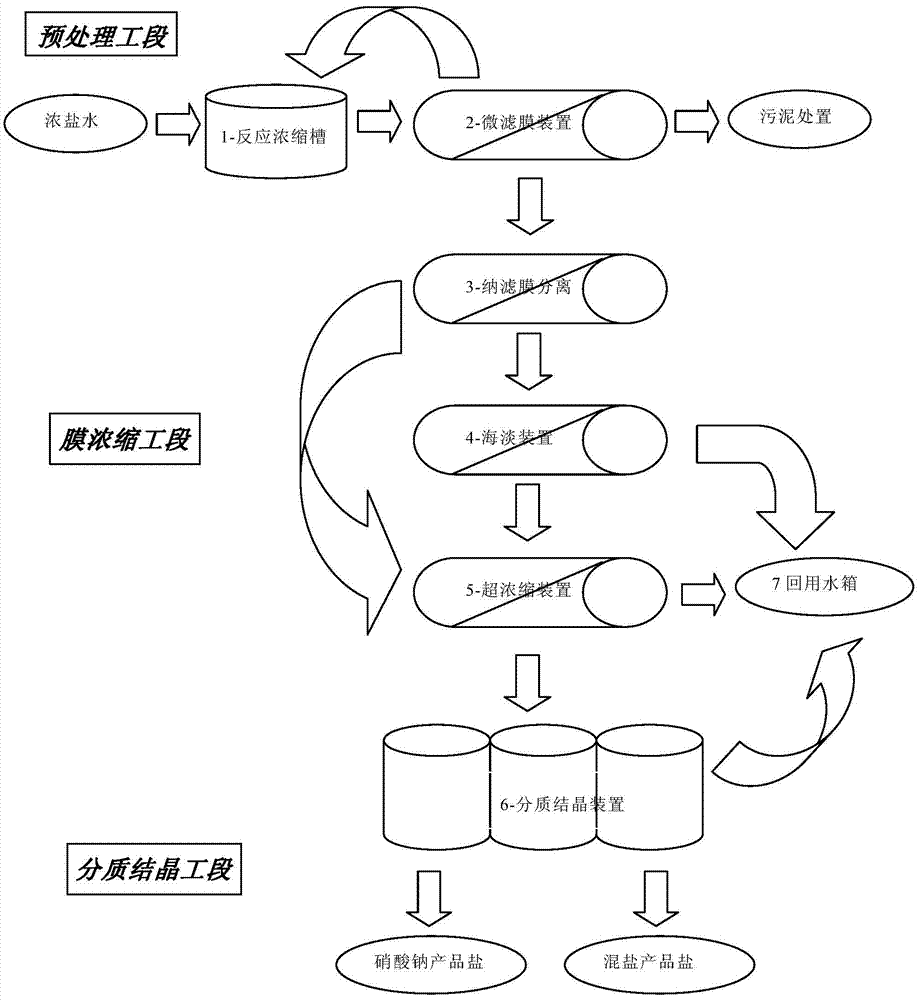

Concentrated salt water zero discharging membrane concentration and quality grading crystallization process and concentrated salt water zero discharging membrane concentration and quality grading crystallization equipment

A membrane concentration and zero discharge technology, which is applied in seawater treatment, water/sewage treatment, general water supply conservation, etc., can solve the problems of lack of systematic process, lack of treatment effect and economy, and inability to complete the whole process treatment, so as to reduce the Operating cost and efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

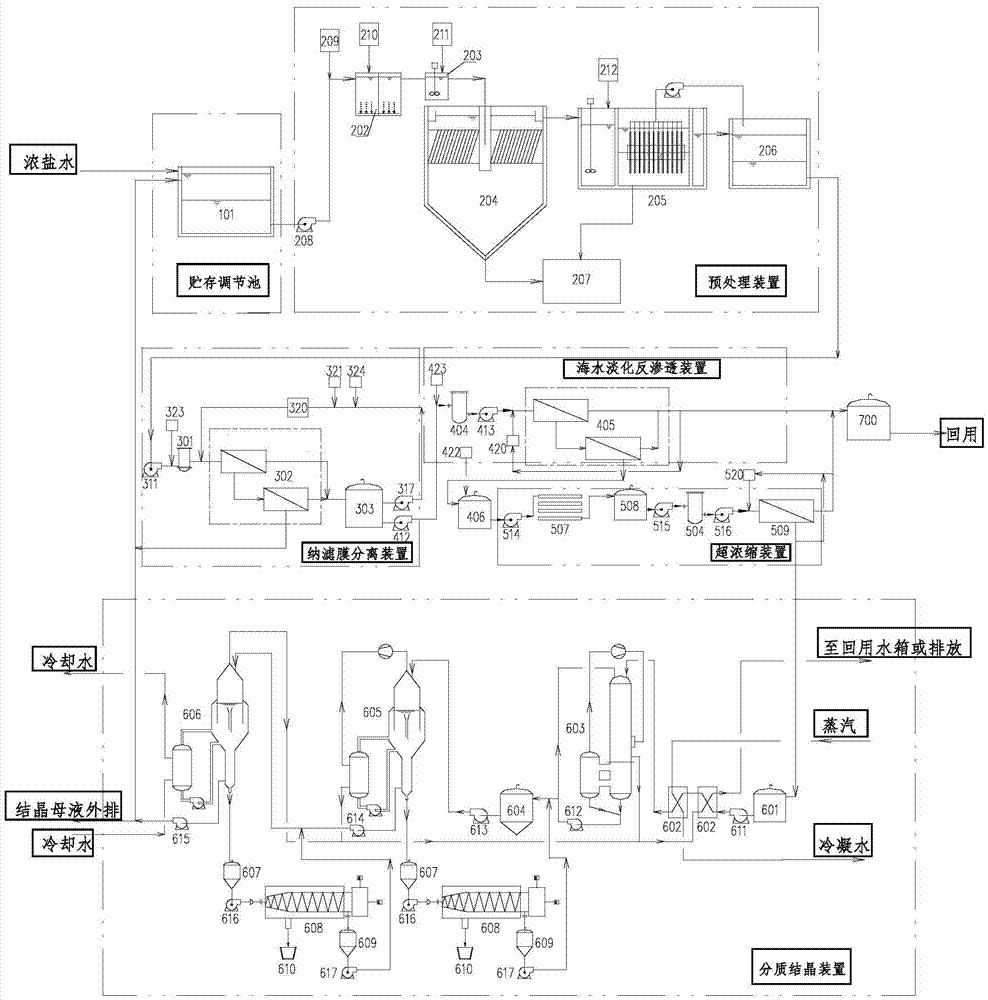

[0038] The concentrated brine enters the storage adjustment tank 1 of the pretreatment device 2 in the pretreatment step. After the water in the pretreatment device 2 passes through the advanced oxidation device, it is fully coagulated and softened by adding softeners such as lime in the sedimentation tank, and then enters the softening micro The filter device performs filtration to remove hardness and turbidity, and remove most of the calcium, magnesium, hardness, alkalinity and suspended impurities in the concentrated brine; the inorganic sludge periodically discharged from the softening microfiltration membrane device is dewatered by pressure filtration, and the filtrate is returned to storage for adjustment Pool 1, the dehydrated cake forms ordinary sludge and solid waste, which is transported out for disposal. The pH of the effluent from the pretreatment device 2 is adjusted back and then enters the nanofiltration membrane separation device 3; the concentrated brine is sepa...

Embodiment 2

[0047] This embodiment is the same as Embodiment 1, except that the advanced oxidation device in the pretreatment device can be an ozone oxidation device (or an ozone catalytic oxidation device, an ozone hydrogen peroxide oxidation device), and the sedimentation tank 204 is omitted. The super concentration device 509 can be a vibrating membrane, a high pressure membrane or a forward osmosis membrane. The membrane softening filter device 205 can be precipitation + immersion ultrafiltration, or precipitation + tubular micro (ultra) filtration membrane, or can be a traditional chemical softening process, that is, drug addition reaction + precipitation + filtration + ultrafiltration. Evaporation concentrator 603 may be multi-effect evaporative concentration or mechanical compression evaporative concentration, and evaporative crystallizer 605 may be multi-effect evaporative crystallizer or mechanical compression evaporative crystallizer. The nanofiltration device 302 is changed to ...

Embodiment 3

[0049] This embodiment is the same as the first embodiment, except that when the hardness of the raw water is low, the membrane softening device 507 in the membrane treatment process can be omitted. When the raw water does not contain nitrate, the frozen crystal 606 and its corresponding centrifugal separation system (607, 608, 609, 610, 616, 617) can be omitted.

[0050] Taking concentrated brine to be treated in a typical coal chemical zero discharge plant as an example, the water inflow is 60m 3 / h, salt content 1.7%, COD300mg / L, total hardness 1000mg / L, total alkalinity 2000mg / L, after this membrane concentration process reduces the amount and reuses, the final super-concentrated brine water volume 3 / h, the overall operating cost 3 . The water produced by the super-concentration device is mixed with the water produced by the front-stage seawater desalination and reverse osmosis device, and the water quality reaches the water quality specified in the national "Urban Sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com