Method for removing organic matters from high organic matter carnallite and recycling inorganic salt

A technology for organic matter and inorganic salts, applied in chemical instruments and methods, alkali metal sulfite/sulfate purification, alkali metal halide purification, etc., can solve the problems of low organic matter removal rate and poor quality of inorganic salts, and achieve Significant energy saving effect, low cost and high salt recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

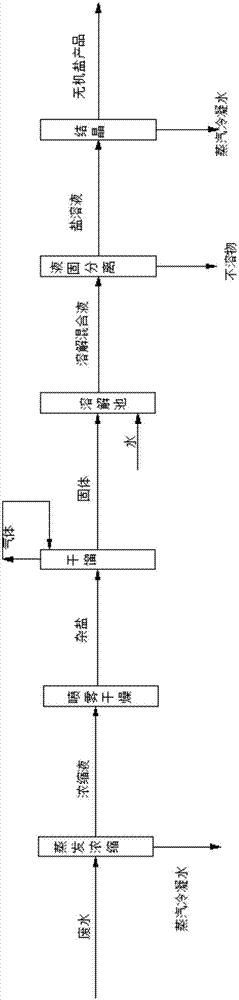

[0040] COD content in wastewater 30000mg / L, Ca 2+ Content 20mg / L, Na + Content 25000mg / L, Cl - Content 38000mg / L, SO 4 2- The content is 1000mg / L, and the technological process of separating and recovering sodium chloride is shown in figure 1 ,include:

[0041] Step 1: Wastewater with high organic content and miscellaneous salt enters the evaporator at 115°C and evaporates under normal pressure until the mass percentage of inorganic salt is 22%; the evaporated water vapor and organic matter with low boiling point are condensed and subjected to biochemical treatment, and the condensed water obtained is reused in step 4;

[0042] Step 2: spray-dry the concentrated solution in step 1 at a temperature of 200°C, and dry to 85% of the content to obtain solid granular salt;

[0043] Step 3: Put the solid in step 2 into a dry distillation furnace, and treat it at 300°C for 300 minutes;

[0044] Step 4: add water to the solid after dry distillation, the mass ratio of water to wat...

Embodiment 2

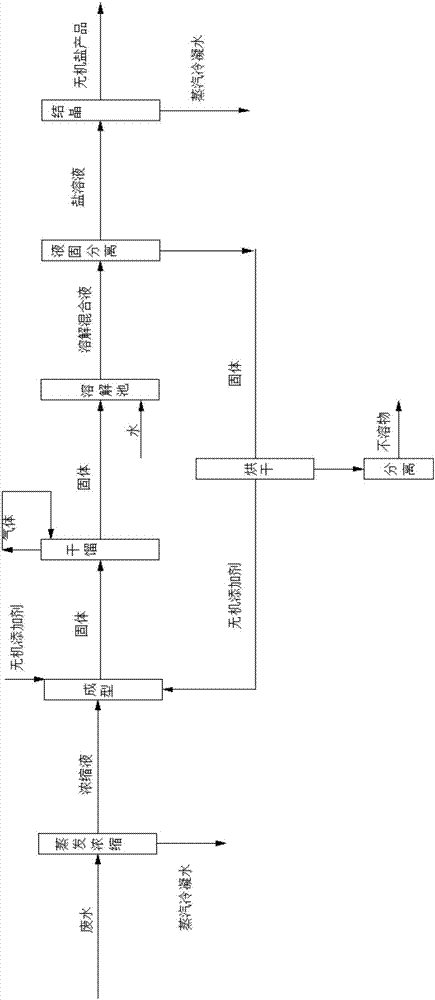

[0048] COD content in wastewater 20000mg / L, Ca 2+ Content 15mg / L, Na + Content 16500mg / L, Cl - Content 25000mg / L, SO 4 2- The content is 500mg / L, and the technological process of separating and recovering sodium chloride is shown in figure 2 ,include:

[0049] Step 1: Wastewater with high organic content and mixed salt enters the evaporator and distills it under reduced pressure at 100°C until the mass percentage of inorganic salt is 25%; the evaporated water vapor and organic matter with low boiling point are condensed and subjected to biochemical treatment, and the condensed water obtained is reused in step 4;

[0050] Step 2: Add carbon powder to the concentrated solution in step 1, wherein the ratio of the concentrated solution to the carbon powder is 1:0.6, and the unit is mL:g, mix it with the concentrated solution, and stir evenly to obtain a powder;

[0051] Step 3: Put the solid in step 2 into a dry distillation furnace, and treat it at 400°C for 200 minutes;

[...

Embodiment 3

[0056] COD content in wastewater 10000mg / L, Ca 2+ Content 10mg / L, Na + Content 13800mg / L, Cl - Content 600mg / L, SO 4 2- The content is 28000mg / L, and the methods for separating and recovering sodium sulfate include:

[0057] Step 1: Wastewater with high organic content and miscellaneous salt enters the evaporator and distills it under reduced pressure at 90°C until the mass percentage of inorganic salt is 25%; the evaporated water vapor and organic matter with low boiling point are condensed and subjected to biochemical treatment, and the condensed water obtained is reused in step 4;

[0058] Step 2: Add fly ash to the concentrated solution in step 1, wherein the ratio of the concentrated solution to the fly ash is 1:4, and the unit is mL:g, mix it with the concentrated solution, and stir evenly to obtain a powder;

[0059] Step 3: Put the solid in step 2 into a dry distillation furnace, and treat it at 550°C for 60 minutes;

[0060] Step 4: add water to the solid after d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com