Method for preparing industrial potassium nitrate by virtue of recrystallization method

A technology of potassium nitrate and crystallization, applied in the field of preparing industrial potassium nitrate by recrystallization method, can solve the problems of high heat transfer coefficient, no scaling, large production capacity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

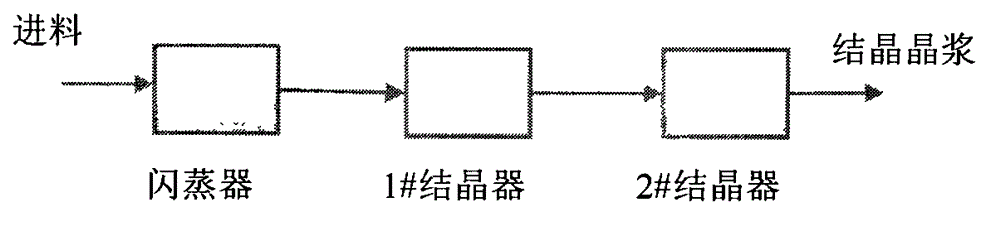

[0049] (1) Embodiment 1: see attached figure 1 . Two-stage continuous crystallization is adopted. The crystallization device is composed of 1 flash evaporator and 2 crystallizers, which are called flash evaporator, 1# and 2# crystallizer respectively. The crude potassium nitrate solution enters the flash evaporator, and then enters 1# from the flash evaporator. Crystallizer, the magma obtained from 1# crystallizer enters 2# crystallizer, 1# and 2# crystallizer magma are connected in series to complete the crystallization process, the temperature of the crude product solution is 70℃~72℃, the saturation is 90%~91%, and the flash evaporator solution Temperature 59℃~61℃, concentration 52%~53%, specific gravity 1.37~1.38, corresponding to flash steam temperature 54℃~56℃, absolute pressure 112~123mmHg column, flasher solution enters 1# crystallizer, 1# crystallizer The liquid phase temperature is 38℃~40℃, the concentration is 37%~39%, the specific gravity is 1.25~1.27, the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com