Treatment method and device for coal chemical industry high-concentration brine

A technology of treatment equipment and treatment method, applied in the field of water treatment, can solve the problems of urgency of resource utilization technology, inability to ensure the purity of sodium chloride and sodium sulfate, and unsatisfactory biochemical treatment of waste water, etc., so as to achieve resource utilization. Utilize, avoid secondary pollution, and realize the effect of comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

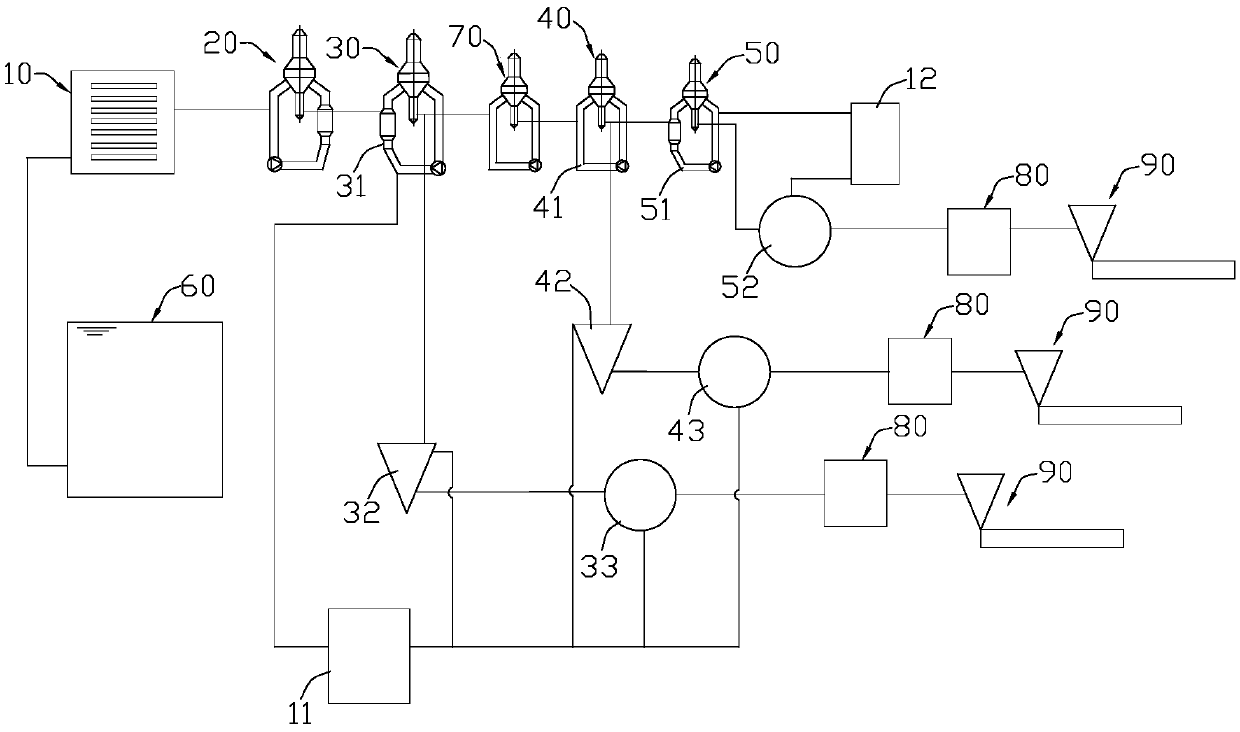

[0041]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

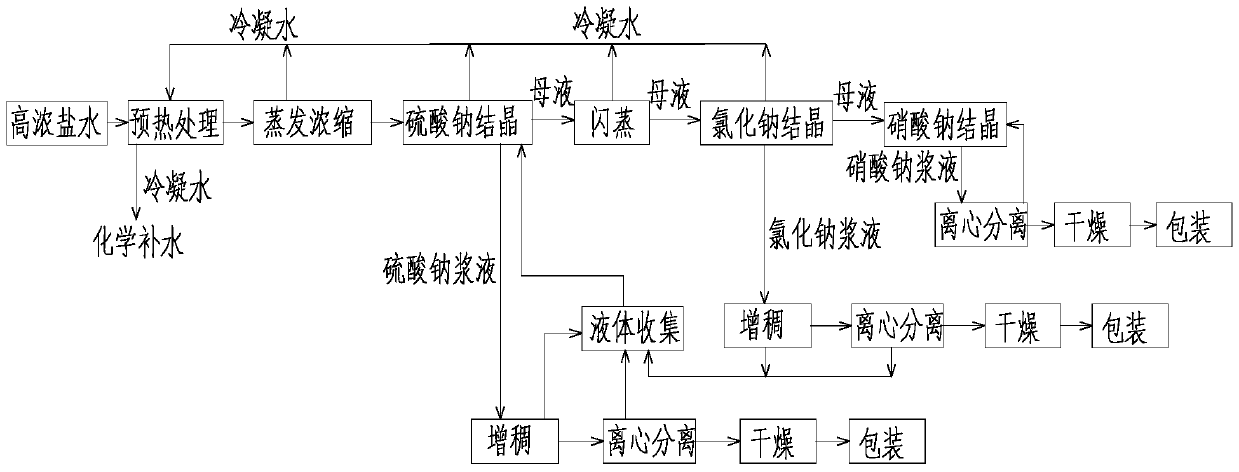

[0042] refer to figure 1 , the coal chemical high-concentration brine treatment method of an embodiment of the present invention may include the following steps:

[0043] S1. Perform preheating treatment and evaporation concentration treatment on the high-concentration brine of the coal chemical industry in sequence.

[0044] In this step S1, part or all of the heat required in the preheating treatment is obtained by exchanging heat with condensed water; Drain the evaporative condensed water produced in the evaporative concentration treatment, sodium sulfate crystal treatment and / or sodium chloride crystal treatment process to the preheating treatment to recycle the heat and reduce energy consumption. The condensed wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com