Balanced circulating mother liquor purification method based on evaporation salt making system

A technology of circulating mother liquor and purification methods, which is applied in the fields of alkali metal nitrate purification, chemical instruments and methods, alkali metal sulfite/sulfite, etc., and can solve the problems of low heat transfer evaporation capacity, large steam consumption, and large heating area and other problems, to achieve the effect of shortened reaction time, high product quality and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

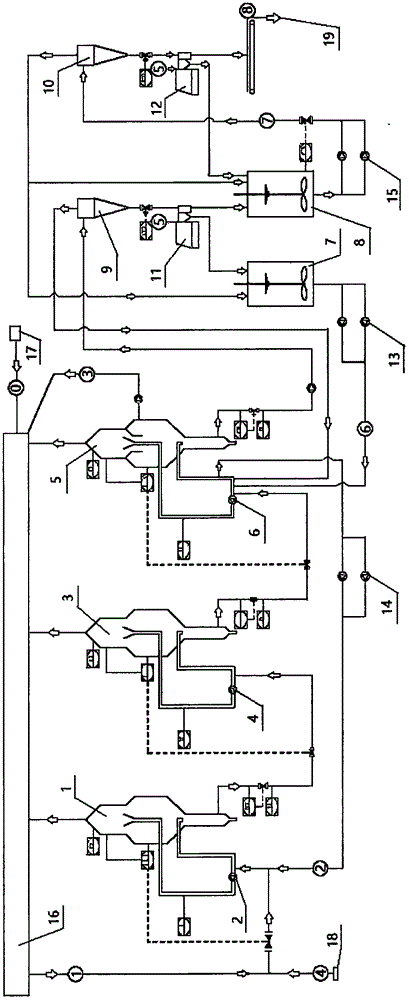

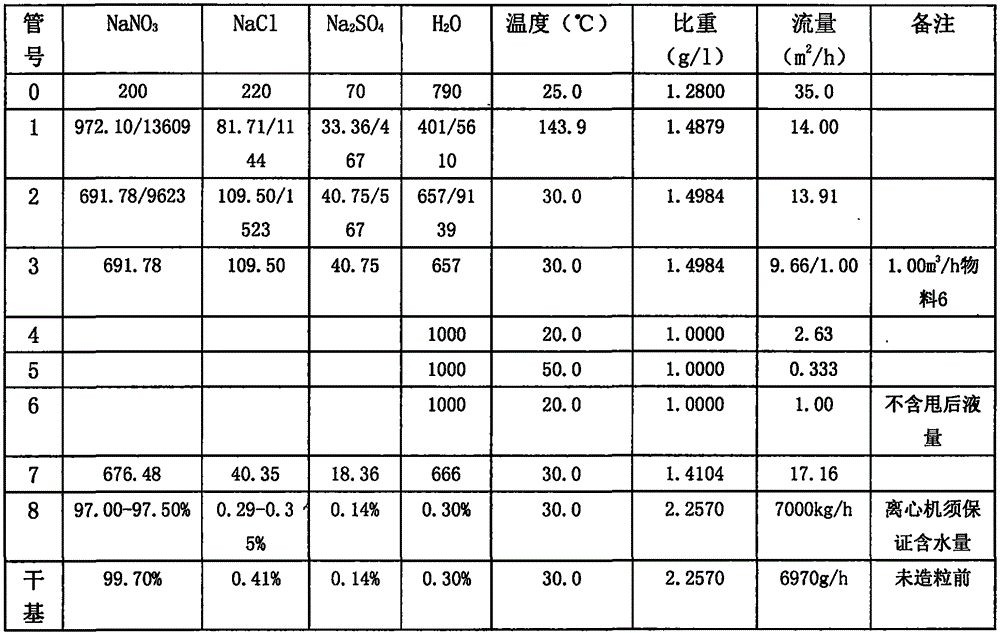

[0028] Embodiment 1: as attached figure 1 As shown, the evaporative salt production system 16 and the fresh water input pipe 18 are connected to the primary evaporation crystallization tank 1, and further connected to the secondary evaporation crystallization tank 3 and the tertiary evaporation crystallization tank 5 in sequence, and the tertiary evaporation crystallization tank 5 is connected and passed through The second chemical pump 14 is connected to the first-stage evaporation crystallization tank 1, the third-stage evaporation crystallization tank 5 is connected to the first hydrocyclone 9, and the top of the first hydrocyclone 9 is connected to the third-stage evaporation crystallization tank 5, and the first hydrocyclone The first centrifuge 11 is connected to the bottom of the flow device 9, and the first centrifuge 11 is connected to the liquid bucket 7 and the stirring tank 8 at the same time, and the liquid bucket 7 is connected to the three-stage evaporation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com