Salt-containing wastewater salt recycling system and method, salt-containing wastewater treatment system and method

A salty wastewater and salt recovery technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased operation, equipment cleaning and maintenance costs, difficult treatment, boiling point Increase and other problems, to achieve the effect of alleviating the tendency of scaling and fouling, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

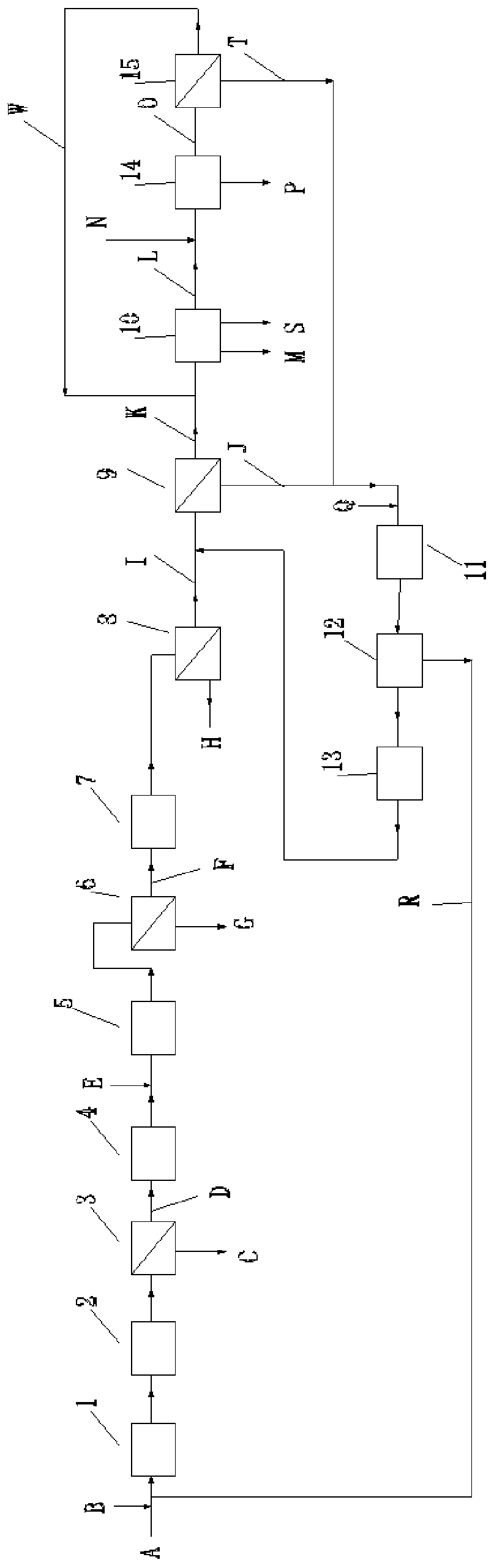

Image

Examples

Embodiment

[0156] Follow the steps below for the treatment of saline wastewater.

[0157] a. The salty wastewater to be treated, the organic concentration is: CODcr 150mg / L, TDS: 8000mg / L, hardness (in terms of CaCO 3 meter) 400mg / L, alkalinity (as CaCO 3 meter) 200mg / L, suspension 5mg / L. Sodium hydroxide, coagulant PFS, soda ash, flocculant PAM, oxidant NaClO and other agents are added to the salty wastewater into the clarifier for clarification and softening treatment. Among them, the dosage of 40% sodium hydroxide is 1.5kg / ton of water, the dosage of coagulant is 15ppm, the dosage of soda ash is 0.4kg / ton of water, the dosage of flocculant is 1.5ppm, and the dosage of oxidant is 50ppm (with effective Chlorine composition meter).

[0158] The clarifier adopts a high-efficiency clarifier, and the upward flow rate in the inclined plate area of the clarifier is designed according to 2.2-2.5mm / S. The suspended matter in the clarifier effluent is less than 10mg / L, and the hardness is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com