Preparation method of high-purity mass potassium nitrate

A technology of potassium nitrate and pure water, which is applied in the purification of alkali metal nitrate, etc., can solve the problems of low purity and unusable potassium nitrate products, and achieve the effects of reducing the content of impurities, reducing energy consumption, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of preparation method of high-purity potassium nitrate

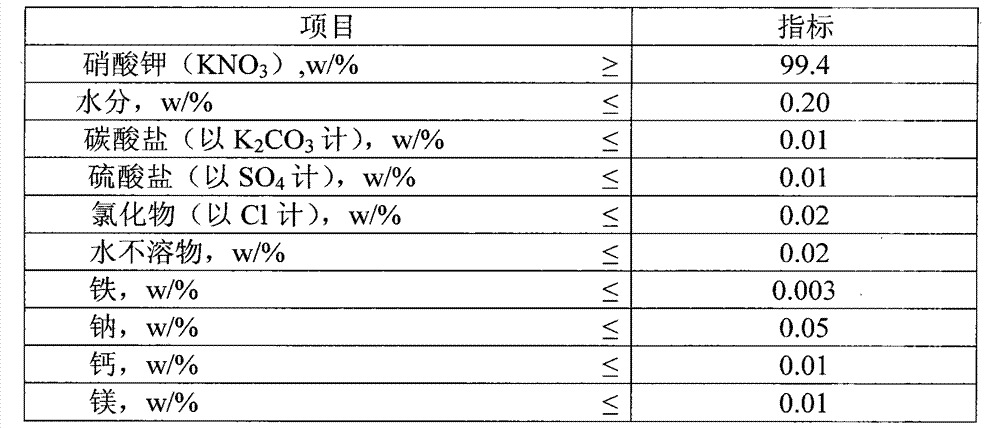

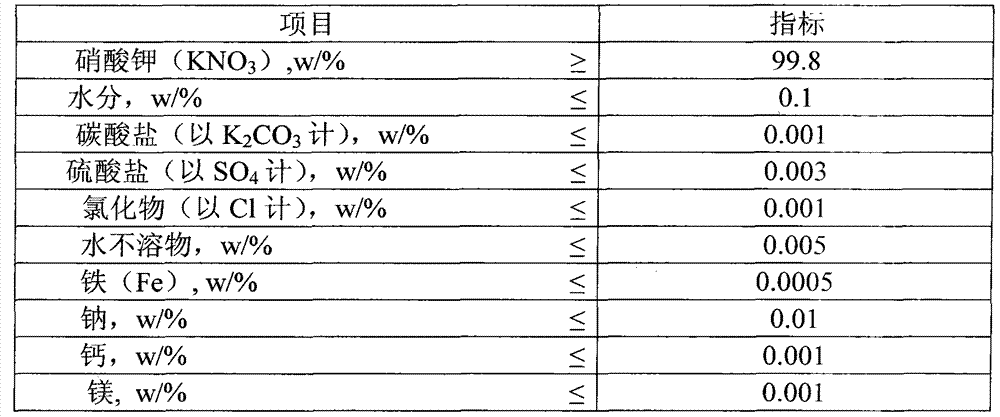

[0032] 3,000 kg of high-purity pure water is produced through a two-stage reverse osmosis water production system, and the conductivity of the water quality does not exceed 10μS / cm, and it is used for standby. Select the potassium nitrate that reaches the national standard (standard GB / T1918-2011), the content reaches 99.4%, and the weight is 3000 kilograms. Put 3000 kg of pure water into the heating reactor and heat it to 75°C. Start stirring, and put 3000 kilograms of ordinary potassium nitrate into the heating reactor. At this time, the temperature should be kept at 75°C, and the mixture should be stirred continuously until it is completely dissolved. After the dissolved potassium nitrate solution is filtered through a filter press, it is sent to a cooler for cooling and crystallization. When the potassium nitrate solution in the cooler is cooled to 20°C, stop cooling. The cooled crysta...

Embodiment 2

[0034] Use the centrifuge of example 1 to wash 300 kilograms of washing liquid in the dehydration separation process, 2700 kilograms of mother liquors, add up to 3000 kilograms. Choose 2000 kg of ordinary potassium nitrate. Put the above mixed solution and potassium nitrate into the heating reactor, stir and heat to 75°C until all the potassium nitrate is dissolved. After the dissolved potassium nitrate solution is filtered through a filter press, it is sent to a cooler for cooling and crystallization. When the potassium nitrate solution in the cooler is cooled to 20°C, stop cooling. The cooled crystallization mixture is sent to an automatic centrifuge for dehydration and separation. During the dehydration process, 350 kg of pure water is used, and the automatic washing program of the centrifuge is used to wash the crystalline potassium nitrate to further dissolve and take away various salt impurities in the potassium nitrate. The crystalline potassium nitrate after washing...

Embodiment 3

[0036] Use the centrifuge washing liquid 350 kilograms in the dehydration separation process of example 1, example 2, mother liquor 2650 kilograms, add up to 3000 kilograms. Choose 3300 kg of ordinary potassium nitrate. Put the above mixed solution and potassium nitrate into the heating reactor, stir and heat to 80°C until all the potassium nitrate is dissolved. After the dissolved potassium nitrate solution is filtered through a filter press, it is sent to a cooler for cooling and crystallization. When the potassium nitrate solution in the cooler is cooled to 30°C, stop cooling. The cooled crystallization mixture is sent to an automatic centrifuge for dehydration and separation. During the dehydration process, 500 kg of pure water is used, and the automatic washing program of the centrifuge is used to wash the crystalline potassium nitrate to further dissolve and take away various salt impurities in the potassium nitrate. The crystalline potassium nitrate after washing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com