Resourceful treatment method of TDI industrial wastewate

A treatment method and technology for industrial wastewater, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of increasing environmental pressure and wastewater treatment costs, reduce the risk of system scaling, and ensure Safe operation and improved crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

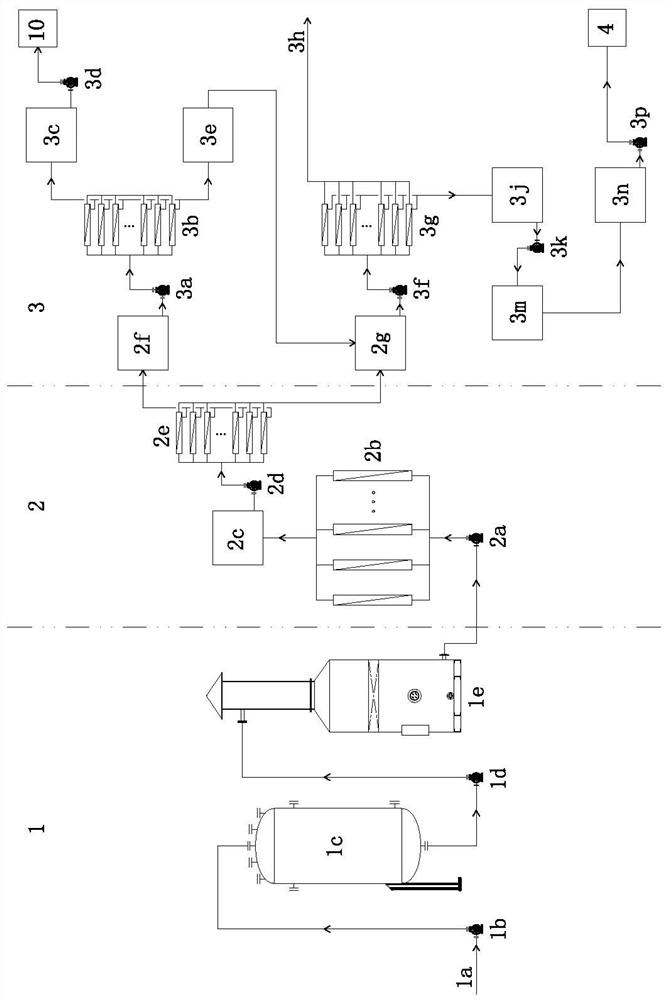

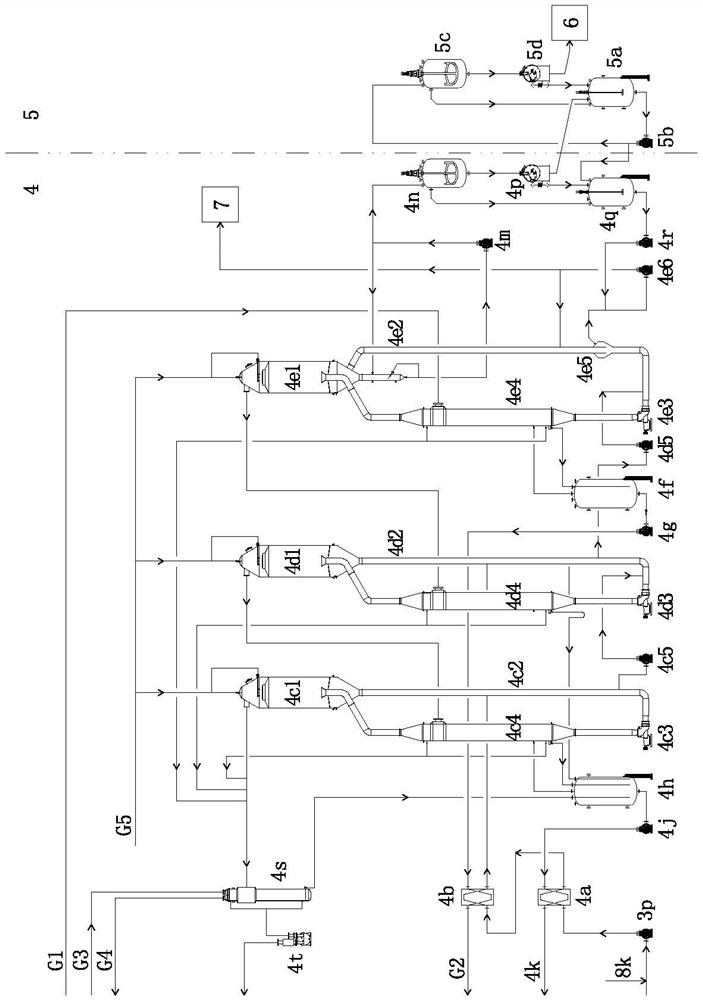

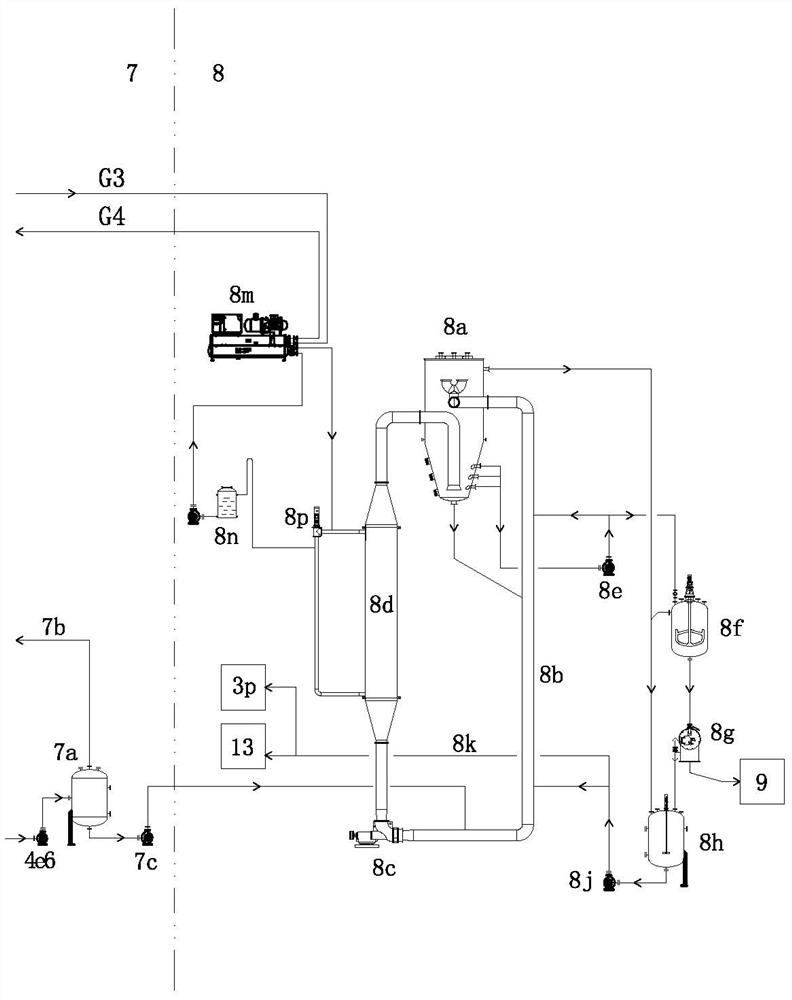

[0028] Such as Figure 1 to Figure 7 As shown, the resourceful treatment method of TDI industrial wastewater of the present invention comprises the following steps in turn: (1) the mixed miscellaneous salt wastewater rich in sodium nitrate, sodium chloride and sodium sulfate removes calcium and magnesium ions and bicarbonate through pretreatment unit 1; ⑵The separation of divalent salt and monovalent salt is realized through the salt separation unit 2; ⑶The divalent salt is re-concentrated to make the concentration of sodium sulfate solution reach 9.86%, and enters the sodium sulfate freeze crystallization unit 10 for freeze crystallization at 0°C; The salt mixed solution is concentrated so that the concentration of sodium chloride reaches 4%, and the concentration of sodium nitrate reaches 9.9%. And separated from the sodium nitrate solution; (5) The sodium nitrate solution is flashed and cooled by the sodium nitrate flash unit 7, and then enters the sodium nitrate cooling cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com