Method and device for preparing bactericide

A bactericide and solution technology, applied in the field of preparation of bactericides, can solve the problems of high power consumption, reduced seawater desalination efficiency, low electrolysis efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

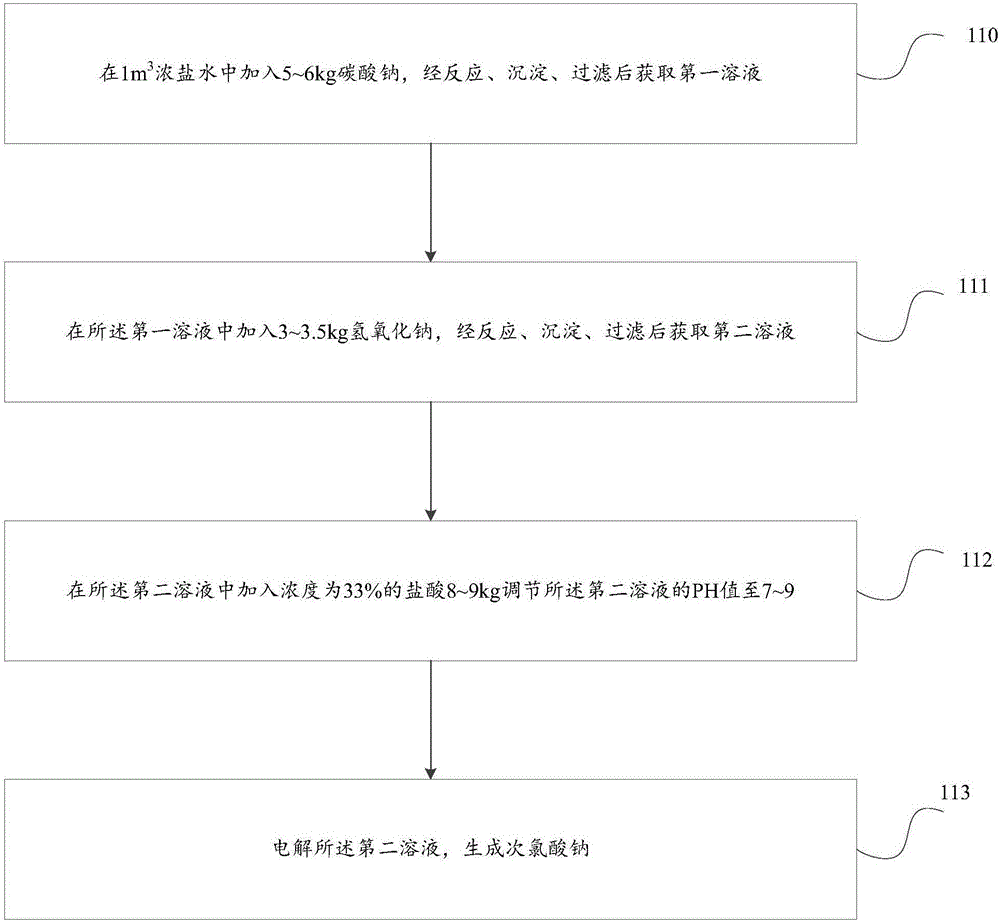

[0039] This embodiment provides a kind of method for preparing fungicide, such as figure 1 As shown, the method includes the following steps:

[0040] Step 110, at 1m 3 Add 5-6 kg of sodium carbonate to the concentrated brine, and obtain the first solution after reaction, precipitation and filtration.

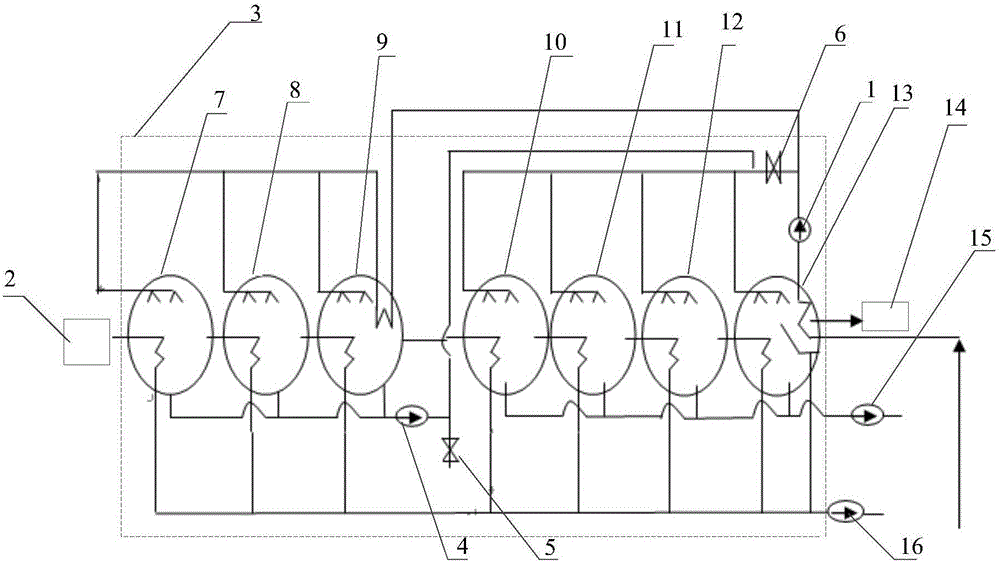

[0041] In this step, firstly, concentrated brine will be prepared using seawater desalination equipment, specifically, as figure 2 As shown, the seawater desalination equipment includes: a booster pump 1, a heat source 2, an evaporator 3, a circulating pump 4, a first regulating valve 5, and a second regulating valve 6; wherein,

[0042] The heat source 2 is used to provide steam for the evaporator 3, and the evaporator 3 utilizes steam to exchange heat with seawater entering the evaporator 3 to obtain finished water and brine. The finished product water refers to water with a salinity rate not greater than 5 mg / L.

[0043] see figure 2 , the evaporator comprises: one-ef...

Embodiment 2

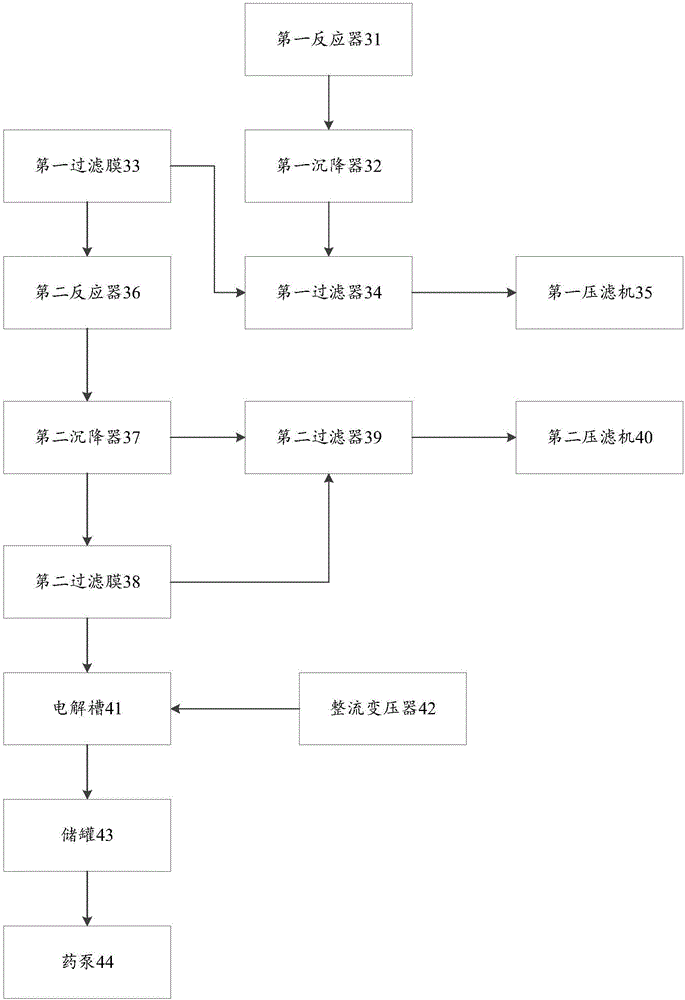

[0079] Corresponding to Embodiment 1, this embodiment also provides a device for preparing bactericide, such as image 3 As shown, the device includes: a first reactor 31, a first settler 32, a first filter membrane 33, a first filter 34, a first filter press 35, a second reactor 36, a second settler 37 , the second filter membrane 38, the second filter 39, the second filter press 40;

[0080] The first reactor 31 is used for 1m 3 The concentrated brine is reacted with 5-6kg of sodium carbonate, and after the reaction, the first reaction solution is obtained. After the first reaction solution is obtained, the first settler 32 is used to settle the first reaction solution to obtain the first solution (ie the solution in the upper layer of the first settler 32 ). After the first solution is obtained, the first filter membrane 33 is used to filter the first solution. Wherein, the first filter membrane 33 may specifically include an ultrafiltration membrane or the like. Here, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com