DTRO guide disc generating vertical-and-horizontal turbulent flow

A deflector, vertical and horizontal technology, which is applied in the field of reverse osmosis membrane element manufacturing, can solve the problems of fouling and blocking, the decline of DTRO performance, and the lack of excessive dependence on pretreatment, so as to achieve excellent tolerance and stable water flow. , The effect of stabilizing the water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

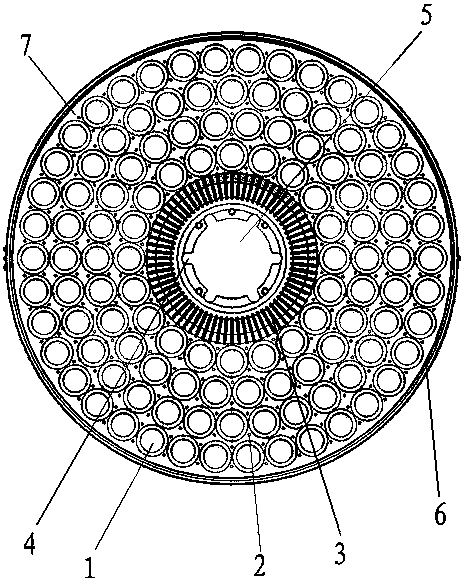

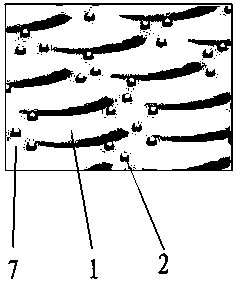

[0019] see figure 1 , a DTRO deflector plate capable of generating vertical and horizontal turbulence, including a plate body, the center of the plate body is provided with a concentrated water turning channel 3, a water production hole 4 and a water production channel 5, and the outer periphery of the plate body is provided with a raised edge 6. Both sides of the disc body are planes, and there are multiple indented pits 1 distributed on both sides of the disc body at intervals, and a plurality of convex holes are distributed on the disc body plane between adjacent pits 1 The bump 2. There is no intersection between adjacent pits 1, and bumps 2 are all distributed on the edge of the pits. The bottoms of the bumps 2 are all on the same plane, and the heights of each bump 2 are the same; the upper edge of the pit 1 is all on the same plane, and it is the same plane as the bottom of the bump 2; the upper edge of the pit 1 After rounded corners, it smoothly transitions to the p...

Embodiment 2

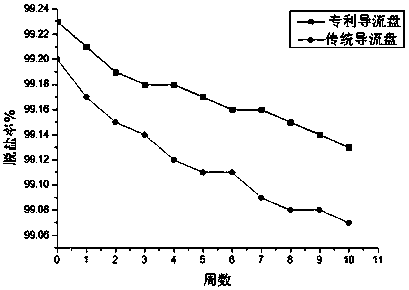

[0021] A membrane column with 209 membrane bags assembled with the diversion disc in the form of bumps and pits in Example 1, and a membrane column with 209 membrane bags assembled with the traditional diversion disc, under the same raw water conditions, the same process Test its desalination rate and permeate decay rate under water pressure (70bar). The DTRO system runs for 8 hours a day and stops for 16 hours. Raw water conditions: 30000us / cm sodium chloride solution, 25°C. The experiment was carried out for 10 weeks.

[0022] Comparison of results of salt rejection rate (%) over time image 3 ; The results of water production (L / h) change with time are compared for example Figure 4 As can be seen from the above experimental data: the DTRO membrane column assembled by the diversion plate in the form of bumps and pits according to the present invention, under the same experimental conditions, the desalination rate attenuation is slower than that of the traditional DTRO memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com