Coal gasification wastewater zero-emission treatment method, and application thereof

A technology of coal gasification wastewater and a treatment method, which is applied in the treatment of zero discharge of coal gasification wastewater and in the field of coal gasification wastewater treatment, can solve problems such as large discharge volume, reduce water volume, reduce investment costs and operating costs, and reduce inorganic salt deposits. The effect of scale risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

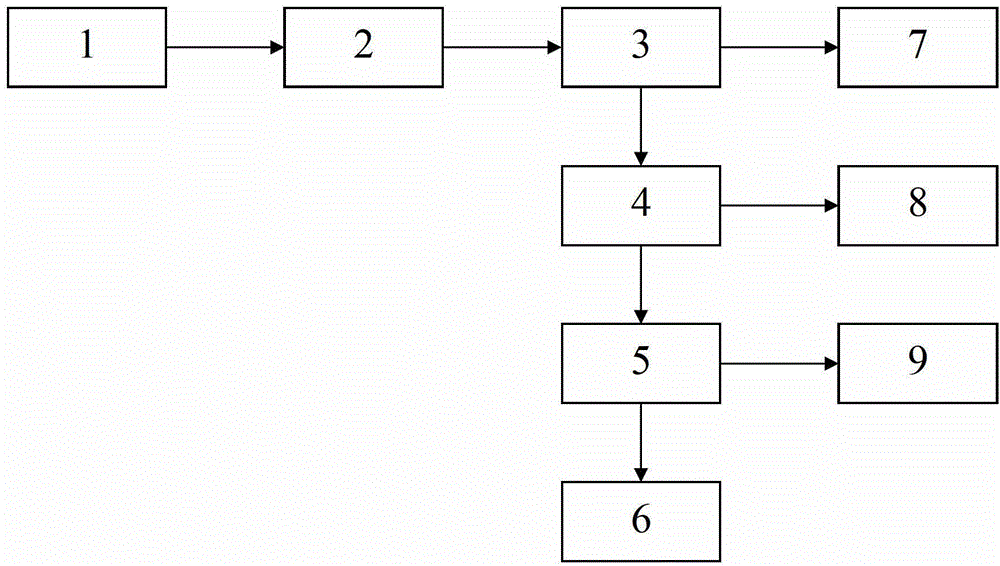

[0048] like figure 1 As shown, the treatment system of the present invention includes a biochemical treatment unit (2), a desalination unit (3), a concentrated brine treatment unit (4) and an evaporation unit (5) including an evaporator.

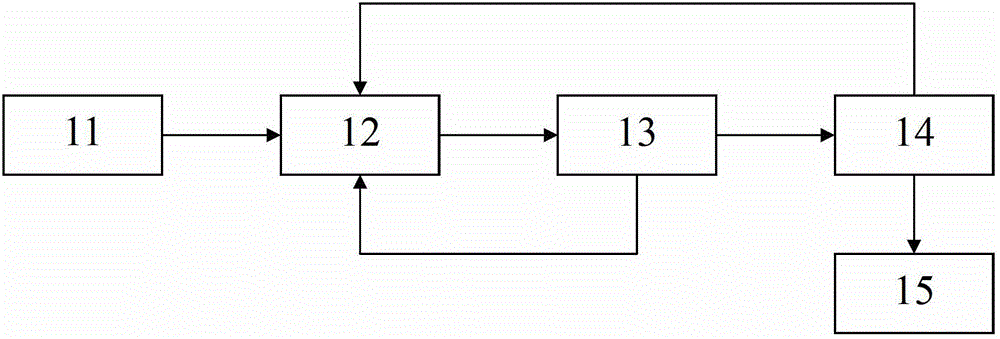

[0049] like figure 2 As shown, the biochemical treatment unit (2) includes an anaerobic tank (11), an anoxic tank (12), an aerobic tank (13) and a sedimentation tank (14) connected in sequence.

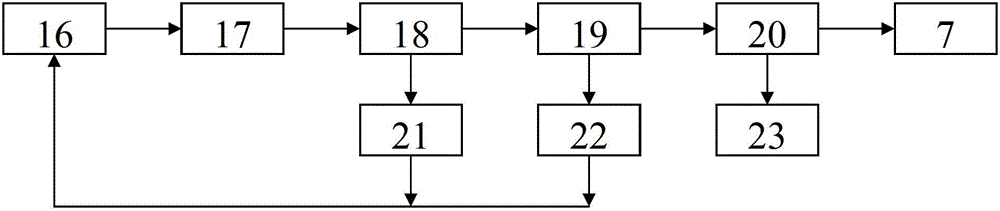

[0050] like image 3 As shown, the desalination unit (3) includes a coagulation sedimentation tank (16) fed with a coagulant, an ozonation reactor (17) fed with ozone (for example, filled with 30% activated carbon Filled circular tower structure ozone oxidation reactor), biological aerated filter (18) (such as biological aerated filter filled with ceramsite filter material inside), the second ultrafiltration system (19) (such as including self- Cleaning filters and ultrafiltration membranes can use submerged ultrafiltration systems made of PVDF ...

Embodiment 2

[0079] As an alternative to the concentrated brine treatment unit (4) described in Example 1, the present invention can also adopt Figure 5 The shown concentrated brine treatment unit ( 4 ) performs concentrated brine treatment.

[0080] like Figure 5 As shown, the concentrated brine treatment unit (4) omits the manganese sand filter (33) connected between the multimedia filter (25) and the first ultrafiltration system (26).

[0081] When the treatment system of this embodiment is used for zero discharge treatment of coal gasification wastewater (1), steps a, b and d in Example 1 can be followed. like Figure 5 As shown, when implementing step c, the effluent from the multimedia filter (25) can be directly passed into the first ultrafiltration system (26).

[0082] When adopting the treatment method of this embodiment to carry out zero-discharge treatment of coal gasification wastewater (1), the following parameters can be used:

[0083] The hydraulic retention time in t...

Embodiment 3

[0102] like Image 6 As shown, the present invention can also use the pretreatment unit (32) to pretreat the coal gasification wastewater (1).

[0103] like Figure 7 As shown, the pretreatment unit (32) includes a regulating tank (10) communicated with the anaerobic tank (11) and provided with a stirring device inside.

[0104] When the treatment system of this embodiment is used for zero discharge treatment of coal gasification wastewater (1), steps b, c and d in Example 2 can be followed. like Figure 7 As shown, when implementing step a, the coal gasification waste water (1) needs to be first passed into the regulating tank (10) and then into the anaerobic tank (11).

[0105] When adopting the treatment method of this embodiment to carry out zero-discharge treatment of coal gasification wastewater (1), the following parameters can be used:

[0106] The hydraulic retention time in the regulating tank (10): 20h,

[0107] The hydraulic retention time in the anaerobic tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com