Fully-automatic production line type potassium nitrate recovering process

An assembly line, potassium nitrate technology, applied in the direction of alkali metal nitrate, alkali metal nitrate purification, alkali metal compounds, etc., can solve problems such as waste, and achieve the effect of being suitable for storage, large production capacity, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

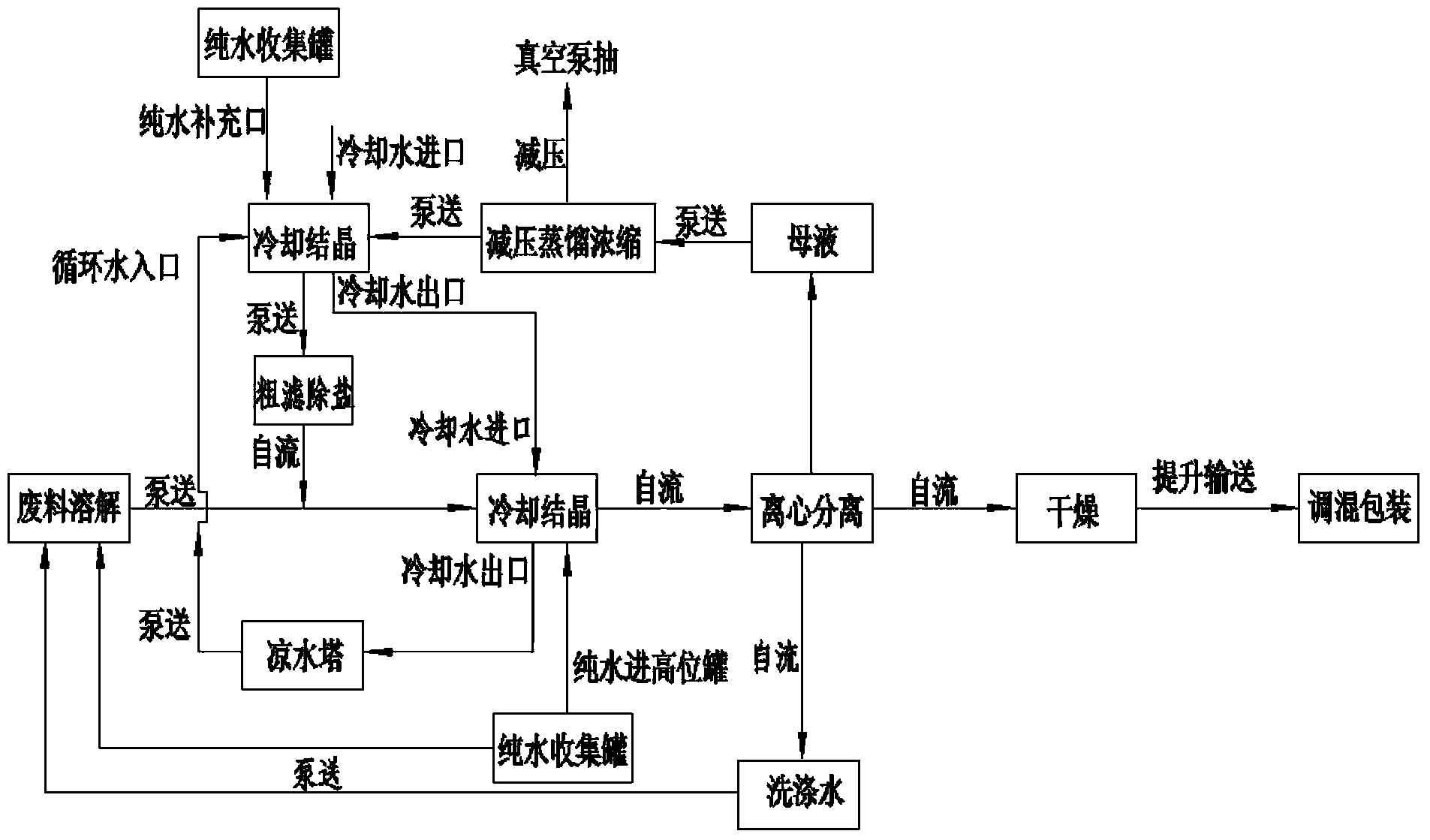

[0016] see figure 1 , the technological process is as follows:

[0017] 1. Waste dissolution

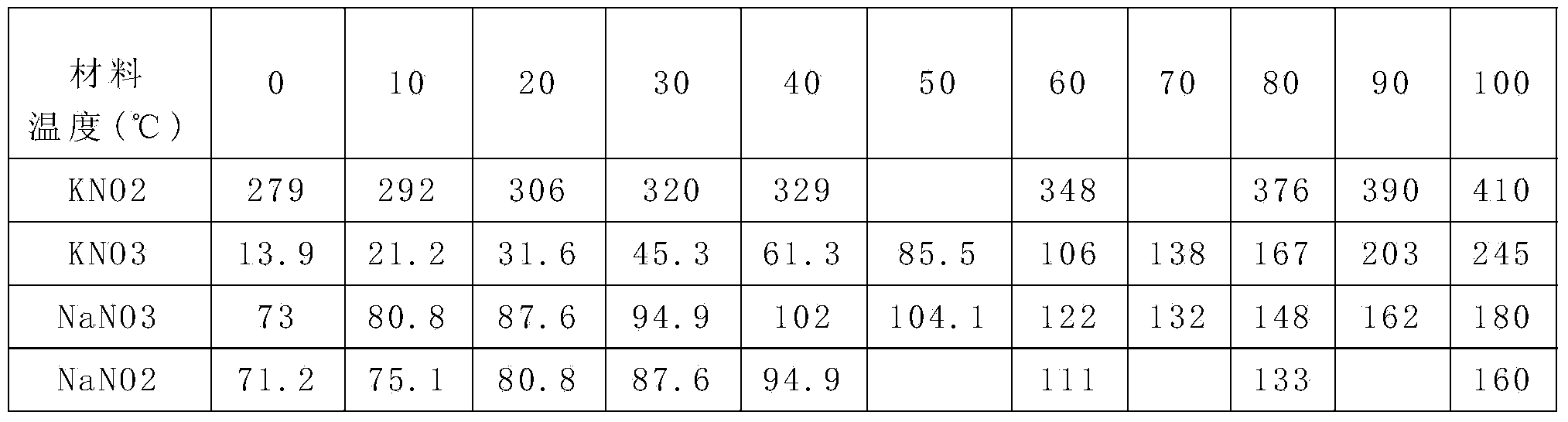

[0018] The waste material is waste potassium nitrate after glass strengthening, containing NaNO3, NaNO2, KNO3, KNO2 and other impurity salts, all of which are easily soluble salts.

[0019] Solution temperature of waste dissolving tank: 110℃~120℃.

[0020] Addition quality of waste materials: Dissolve 300g-350g of waste potassium nitrate in 100g of water.

[0021] Dissolving time of waste: the user can adjust the power of the heater to control it according to the situation. If the dissolution time needs to be prolonged, the heater power can be increased; if the dissolution time needs to be shortened, the heater power can be reduced.

[0022] Other technical requirements: The waste dissolving tank needs to add a stirrer to speed up the dissolving of waste, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com