Tempered glass strength detecting device

A strength detection and tempering technology, applied in the direction of applying stable tension/pressure to test the strength of materials and test the hardness of materials, etc., can solve the problem that the glass detection device is not suitable for batch testing of tempered glass, and achieve the effect of preventing damage and splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

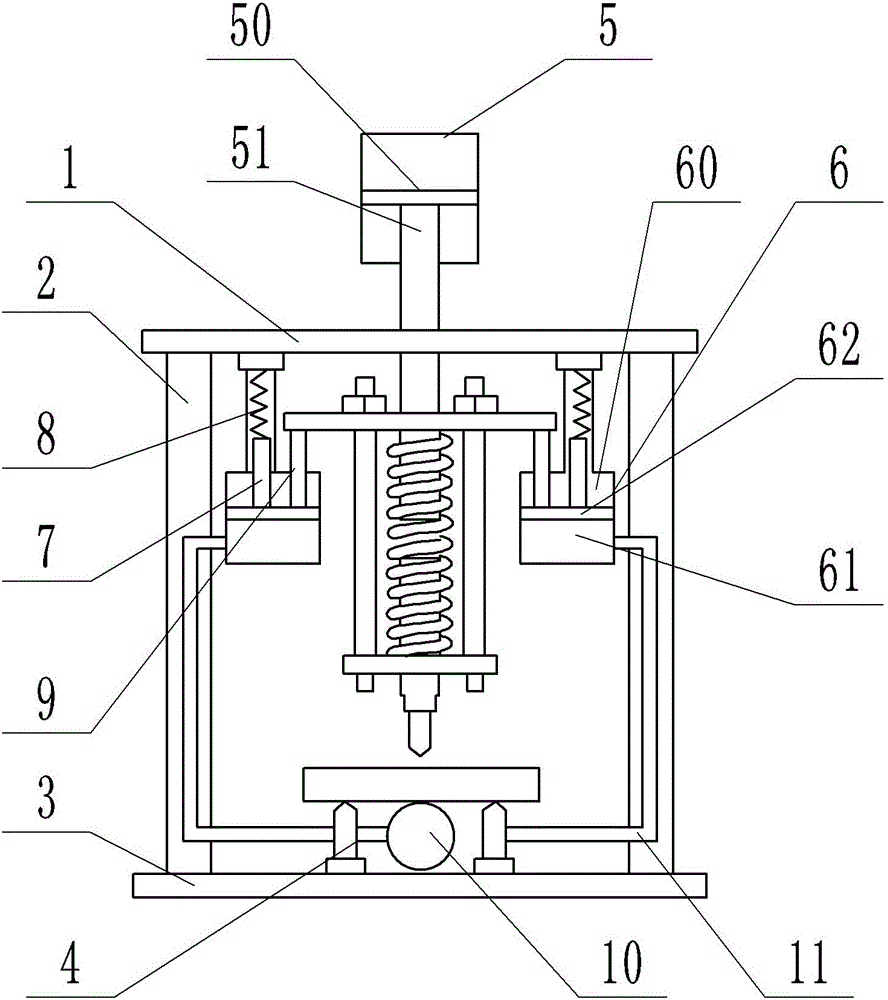

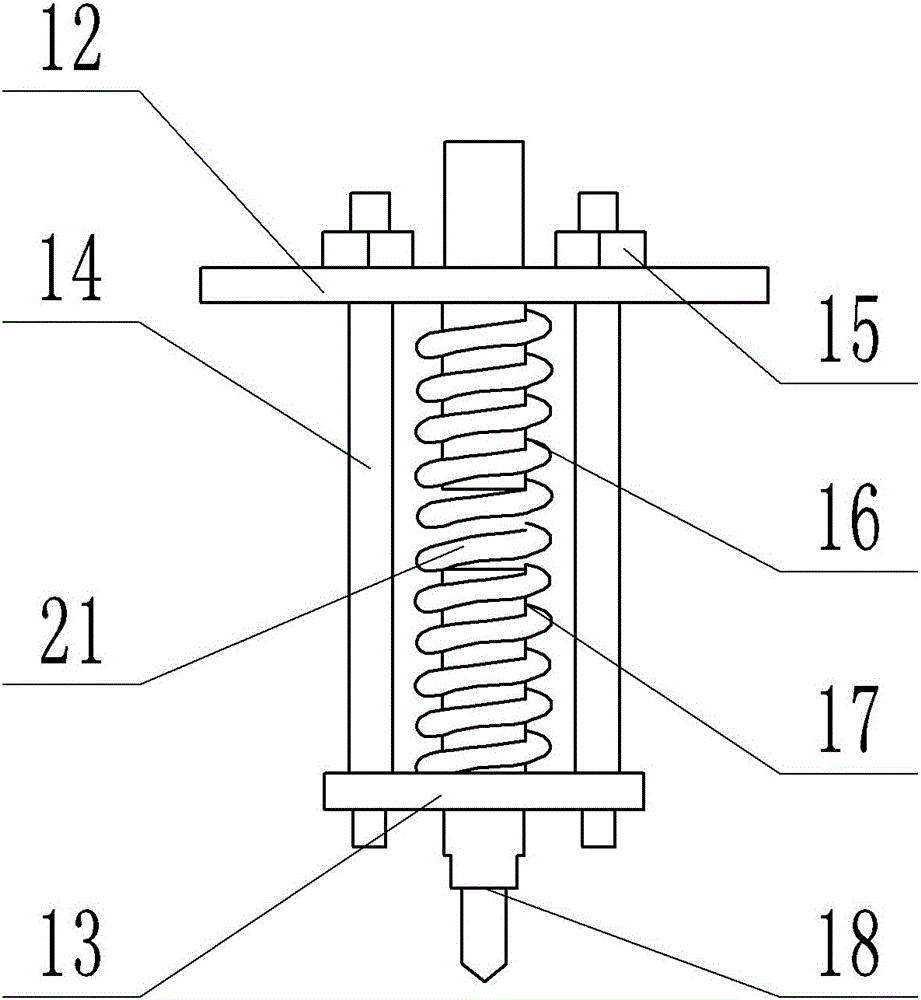

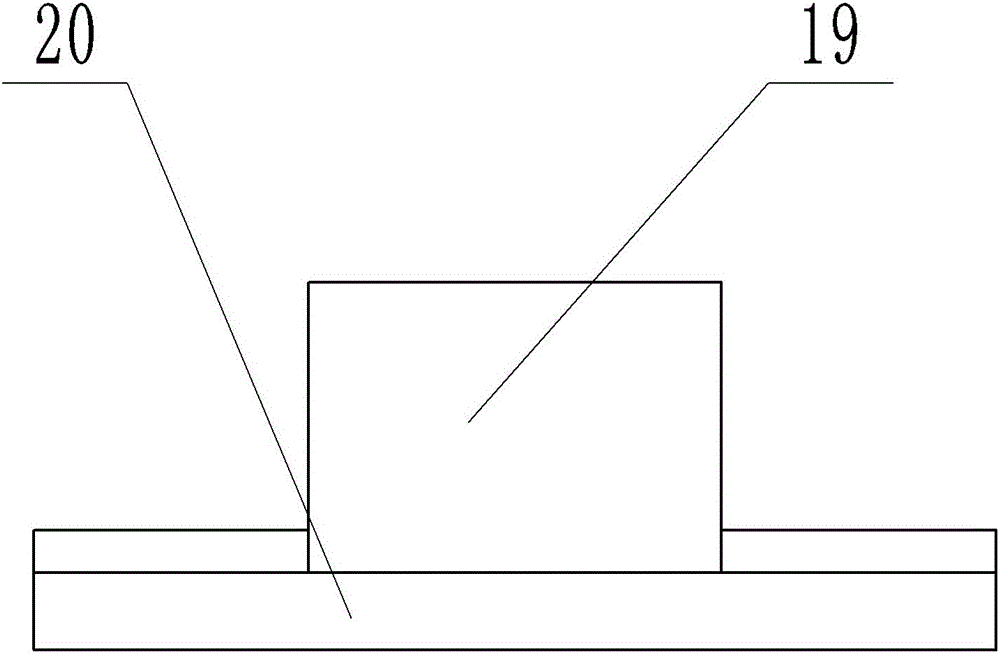

[0018] The reference signs in the accompanying drawings include: top plate 1, support column 2, bottom plate 3, support block 4, cylinder 5, piston 50, piston rod 51, hydraulic cylinder 6, upper cylinder 60, lower cylinder 61, push plate 62, First connecting rod 7, second spring 8, sheath 80, bracket block 81, second connecting rod 9, hydraulic air bag 10, catheter 11, upper fixing plate 12, lower fixing plate 13, guide rod 14, nut 15. Leading rod 16, pressure rod 17, test piece 18, protective device 19, guide rail 20, second spring 21.

[0019] The embodiment is basically as attached figure 1 , figure 2 Shown: a tempered glass plate strength testing device, including a frame, a detection component, a second spring 21, a cylinder 5 and a second spring 8, the frame includes a top plate 1, a support column 2 and a bottom plate 3, and the two ends of the support column 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com