Lithium disilicate microcrystalline glass and preparation method thereof

A lithium disilicate and glass-ceramic technology, which is applied in the field of lithium disilicate glass-ceramics and its preparation, can solve the problems of decreased transparency, lack of vividness, and ugly appearance of materials, so as to improve strength, toughness and ensure stability and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

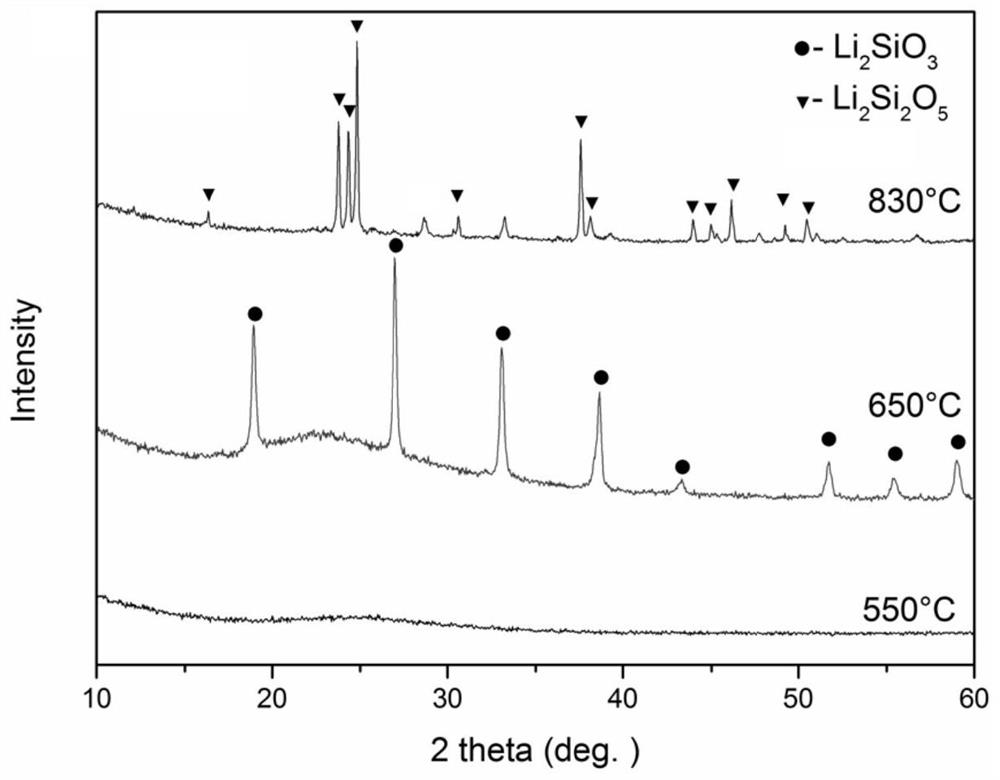

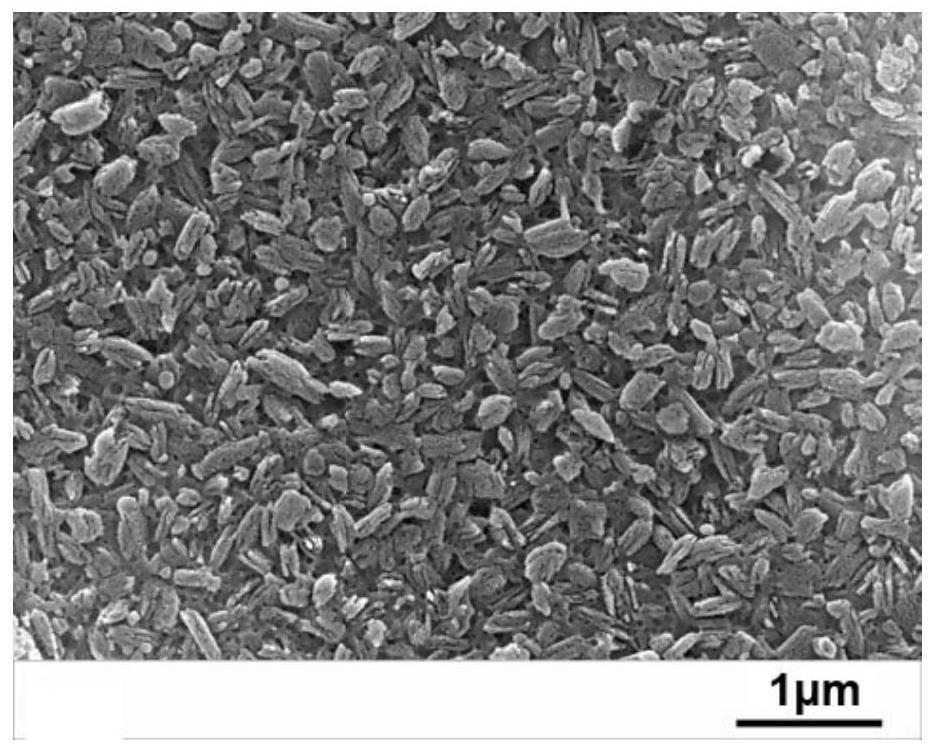

[0037] The invention prepares high-strength and high-toughness lithium disilicate glass-ceramics with coexistence of multi-scale crystals. The method includes melting of transparent hard glass with lithium disilicate composition and heat treatment analysis of transparent hard glass with lithium disilicate composition. Crystallization obtains lithium disilicate glass-ceramics, specifically according to the following steps:

[0038] (1) Mixing of raw materials: Li 2 O, SiO 2 、Na 2 O.B 2 o 3 , ZnO, Al 2 o 3 , MgO, P 2 o 5 , ZrO 2 、K 2 O and rare earth oxides are evenly mixed to obtain a mixture. The specific ratio of raw materials is shown in Table 1 below.

[0039] The mass percent (wt.%) of each raw material of table 1 embodiment 1

[0040] Li 2 o

SiO 2

Na 2 o

B 2 o 3

ZnO Al 2 o 3

MgO P 2 o 5

ZrO 2

K 2 o

rare earth total 22 55 4 2.5 3 3 2 2 3 2 1.5 100

[0041] (2) Use absolute...

Embodiment 2

[0054] (1) Adopt the method as described in embodiment 1 to make the transparent hard glass of lithium disilicate composition.

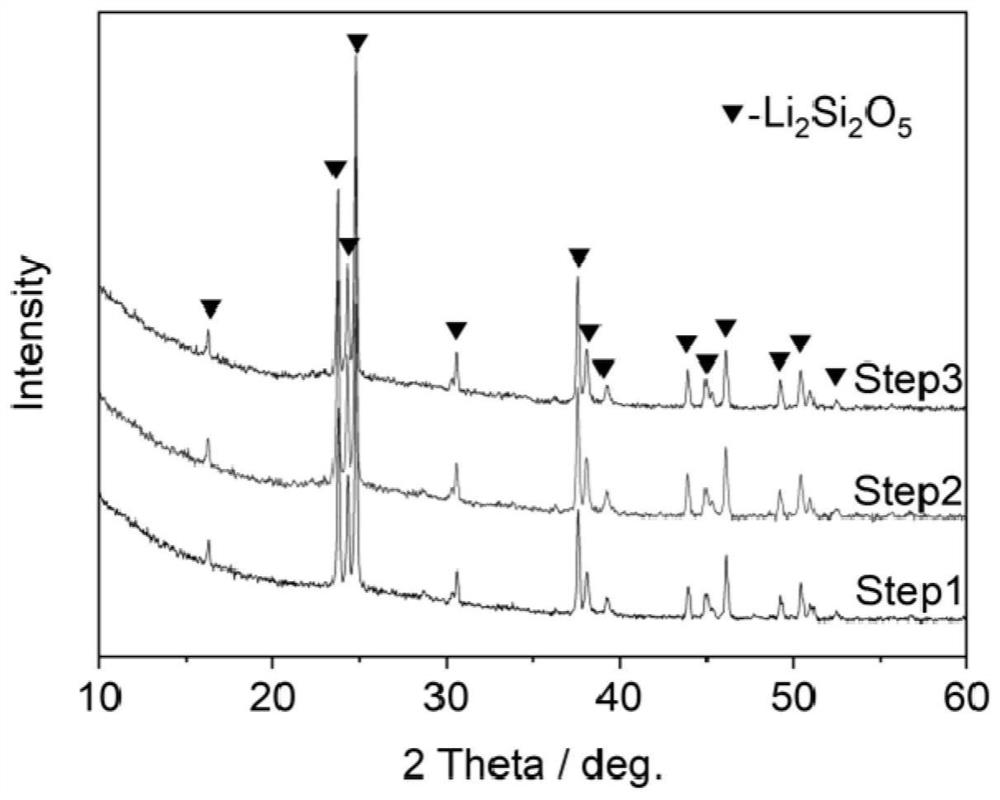

[0055] (2) The first heat treatment of lithium disilicate glass-ceramics: a three-stage heat treatment process is adopted, and the heating system is ①500°C, 2h, ②675°C, 2h, ③815°C, 24h. After one-step heat treatment, lithium disilicate grains with relatively uniform size are precipitated in the glass.

[0056] (3) The second step heat treatment of lithium disilicate glass-ceramics: the glass-ceramics where lithium disilicate has been precipitated is rapidly heated to 965° C. at a heating rate of 75° C. / min, and then kept for 140 minutes. After the two-step heat treatment, the lithium disilicate crystals are partially remelted, a secondary recrystallization process occurs, and finally coarse lithium disilicate grains are formed.

[0057] (4) The third step heat treatment of lithium disilicate glass-ceramics: heat the lithium disilicate glass-ceramics...

Embodiment 3

[0060] (1) Preparation of transparent hard glass with lithium disilicate component as described in Example 1.

[0061] (2) The first heat treatment of lithium disilicate glass-ceramics: a three-stage heat treatment process is adopted, and the heating system is ①550°C, 2h, ②600°C, 12h, ③875°C, 2h. After one-step heat treatment, lithium disilicate grains with relatively uniform size are precipitated in the glass.

[0062] (3) The second heat treatment of lithium disilicate glass-ceramics: the glass-ceramics where lithium disilicate has been precipitated is rapidly heated to 1035° C. at a heating rate of 90° C. / min, and then kept for 12 minutes. After the two-step heat treatment, the lithium disilicate crystals are partially remelted, a secondary recrystallization process occurs, and finally coarse lithium disilicate grains are formed.

[0063] (4) The third step heat treatment of lithium disilicate glass-ceramics: heat the lithium disilicate glass-ceramics that has undergone th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Crystal diameter | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com