Method for testing bending strength of ultra-thin glass

An ultra-thin glass, strength testing technology, applied in the direction of using a stable bending force to test the strength of materials, can solve the problems of unsuitability for ultra-thin glass, complex static analysis, deviation of results, etc. The effect of strong operability and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

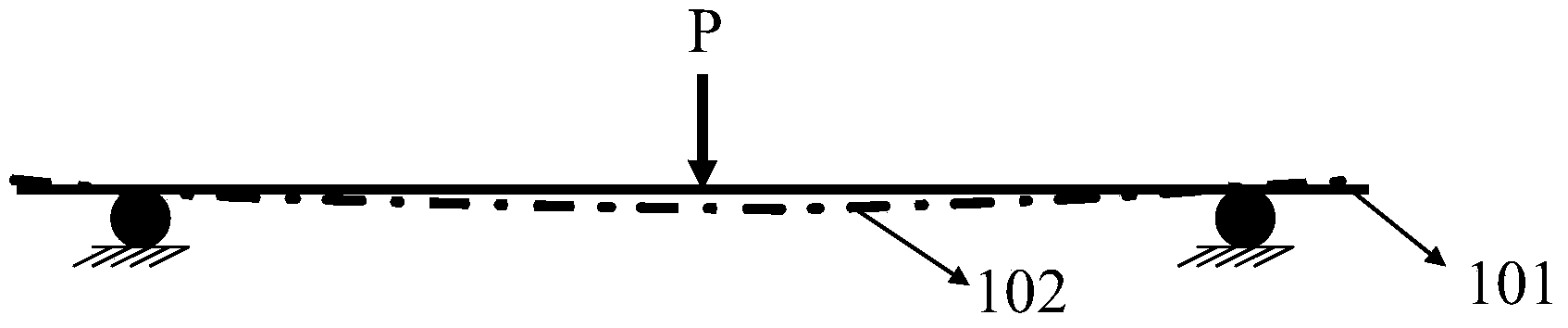

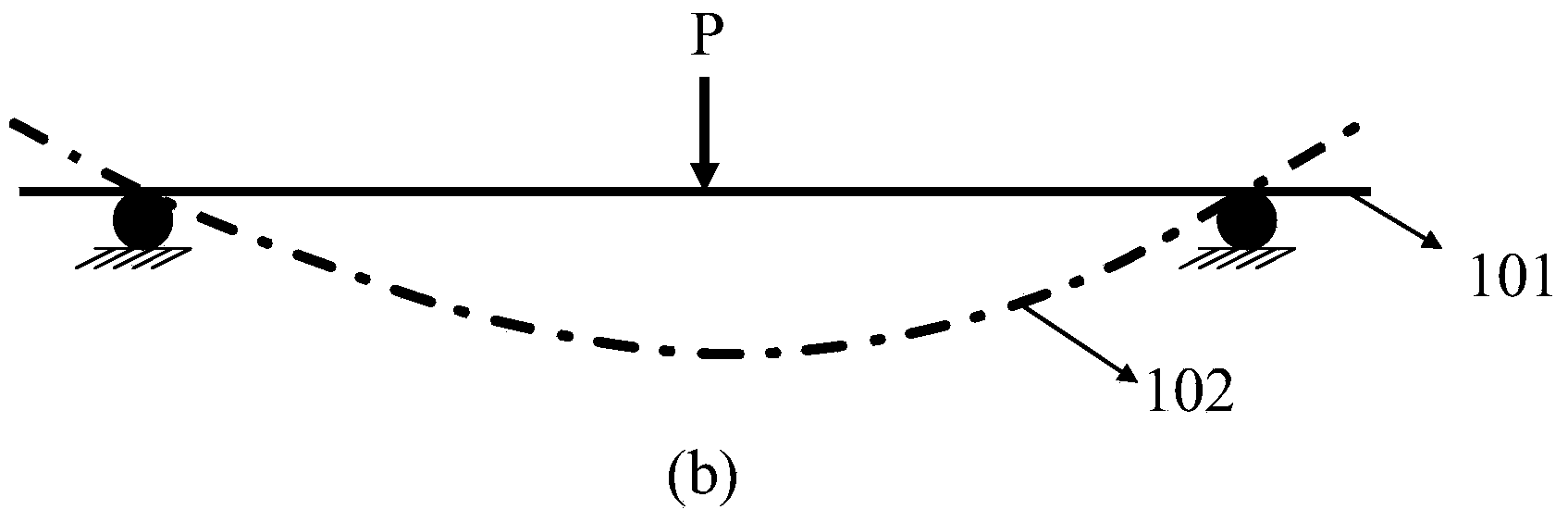

[0036] A method for testing the strength of ultra-thin glass, comprising:

[0037] Obtain the modulus of elasticity of the object;

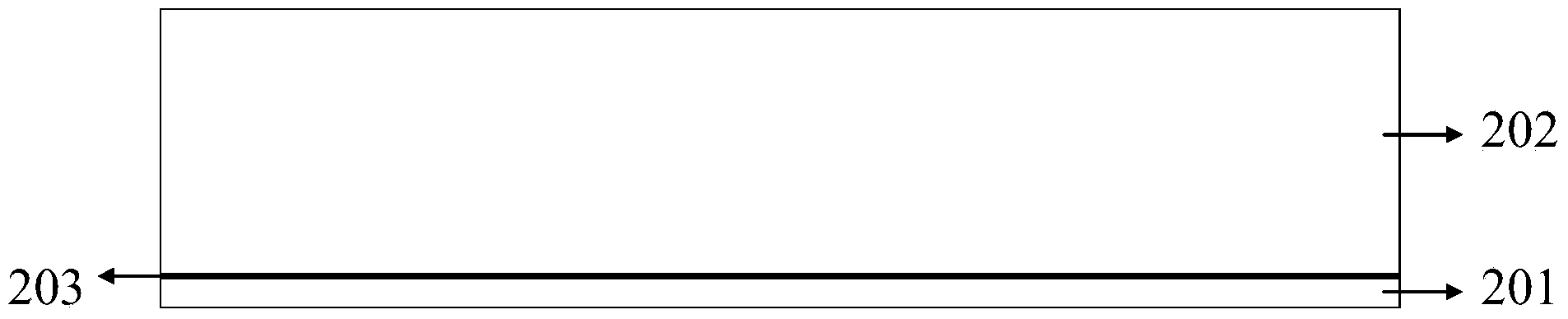

[0038] Fix the object and the ultra-thin glass to be tested together to form a composite object sample;

[0039] Through the existing glass strength test method, measure the force value corresponding to the glass fracture moment of the composite sample, and substitute it into the given calculation formula to obtain the ultra-thin glass bending strength;

[0040] The objects are standard beams or blocks.

[0041] The modulus of elasticity of the object needs to be measured before the test and is determined as a known parameter. The composite beam or block formed by the bonding of ultra-thin glass and sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com