Environment-friendly UV glue applied to flexible packaging film

A flexible packaging film, environment-friendly technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of production risks, great impact of quality accidents, large area occupied by production equipment, etc., to achieve Reduce quality accidents and accident costs, improve production efficiency, and reduce the effect of production sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

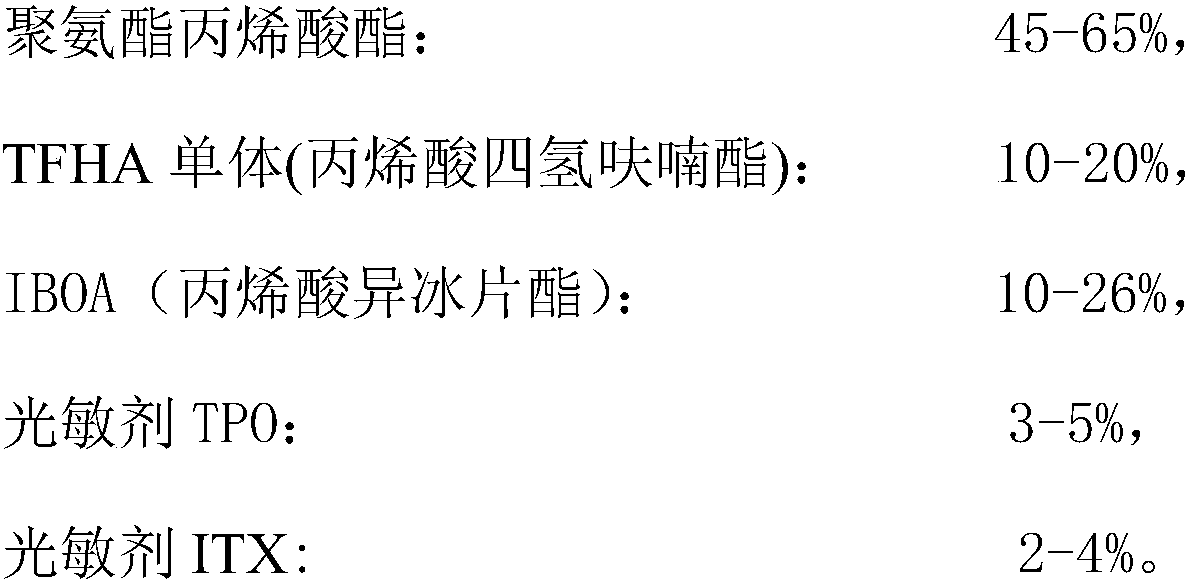

[0036] A kind of environment-friendly UV glue applied to flexible packaging film, comprising the following components by weight percentage:

[0037]

[0038] Preparation:

[0039] (1) take raw materials according to the weight percentage of formula;

[0040] (2) Feed urethane acrylate, TFHA monomer, IBOA, photosensitizer TPO and ITX in sequence, set the stirring speed at 1200r / min, stir for 20 minutes until the materials are evenly stirred, and then get the environmentally friendly UV glue.

Embodiment 2

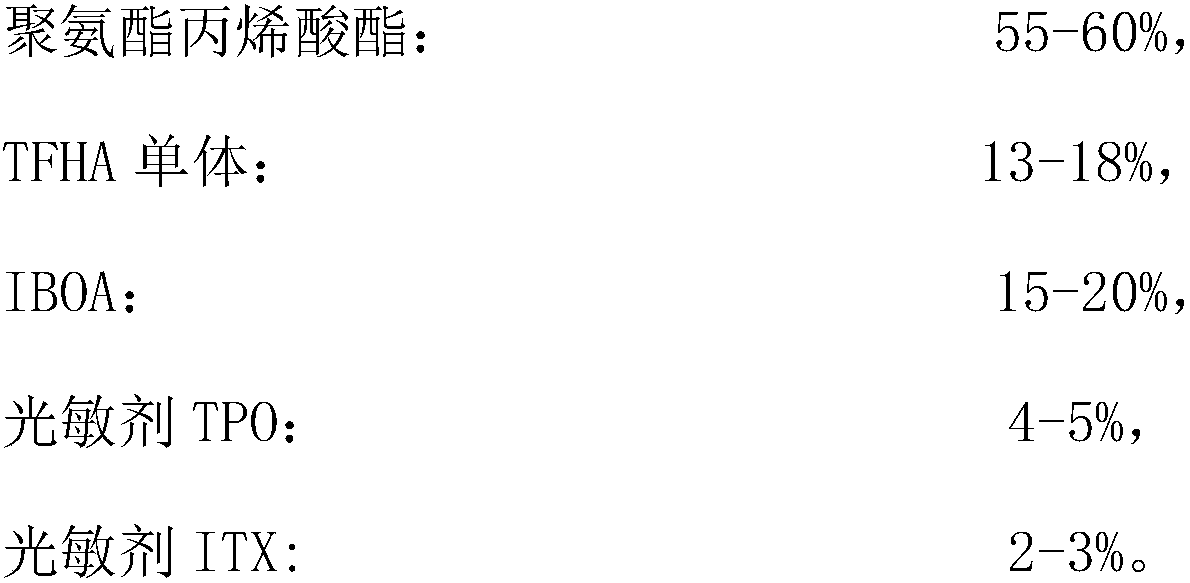

[0042] A kind of environment-friendly UV glue applied to flexible packaging film, comprising the following components by weight percentage:

[0043]

[0044] The preparation method is the same as in Example 1.

Embodiment 3

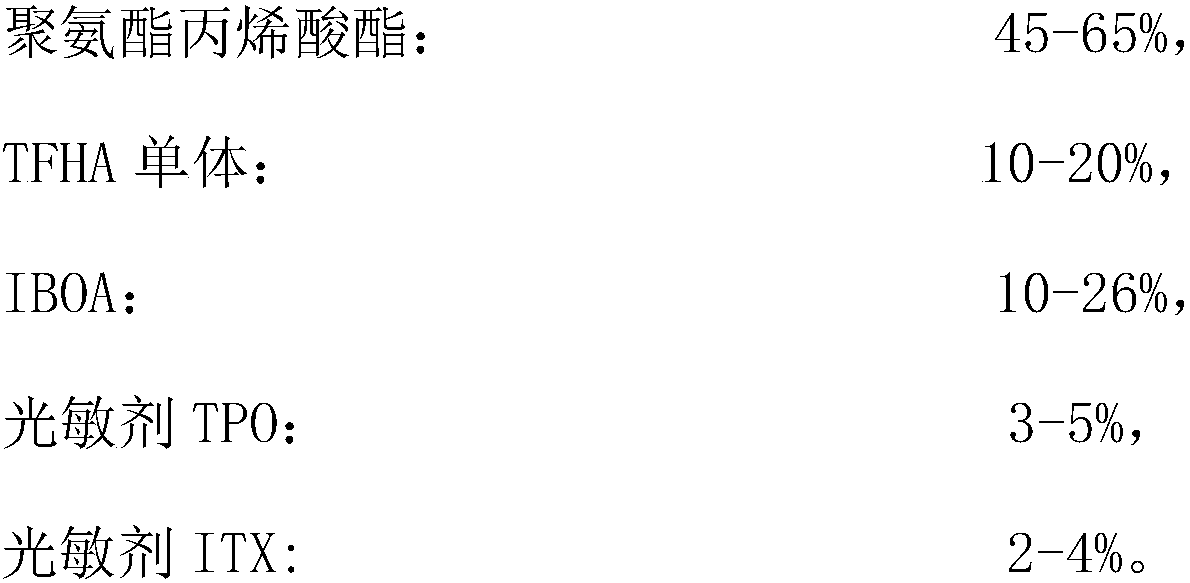

[0046] A kind of environment-friendly UV glue applied to flexible packaging film, comprising the following components by weight percentage:

[0047]

[0048] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com