Glass toughening method and toughened glass

A glass strengthening and tempering glass technology, applied in the field of glass processing, can solve the problems of low tensile strength, micro-crack expansion, glass breakage, etc., and achieve the effect of improving glass strength, easy operation and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

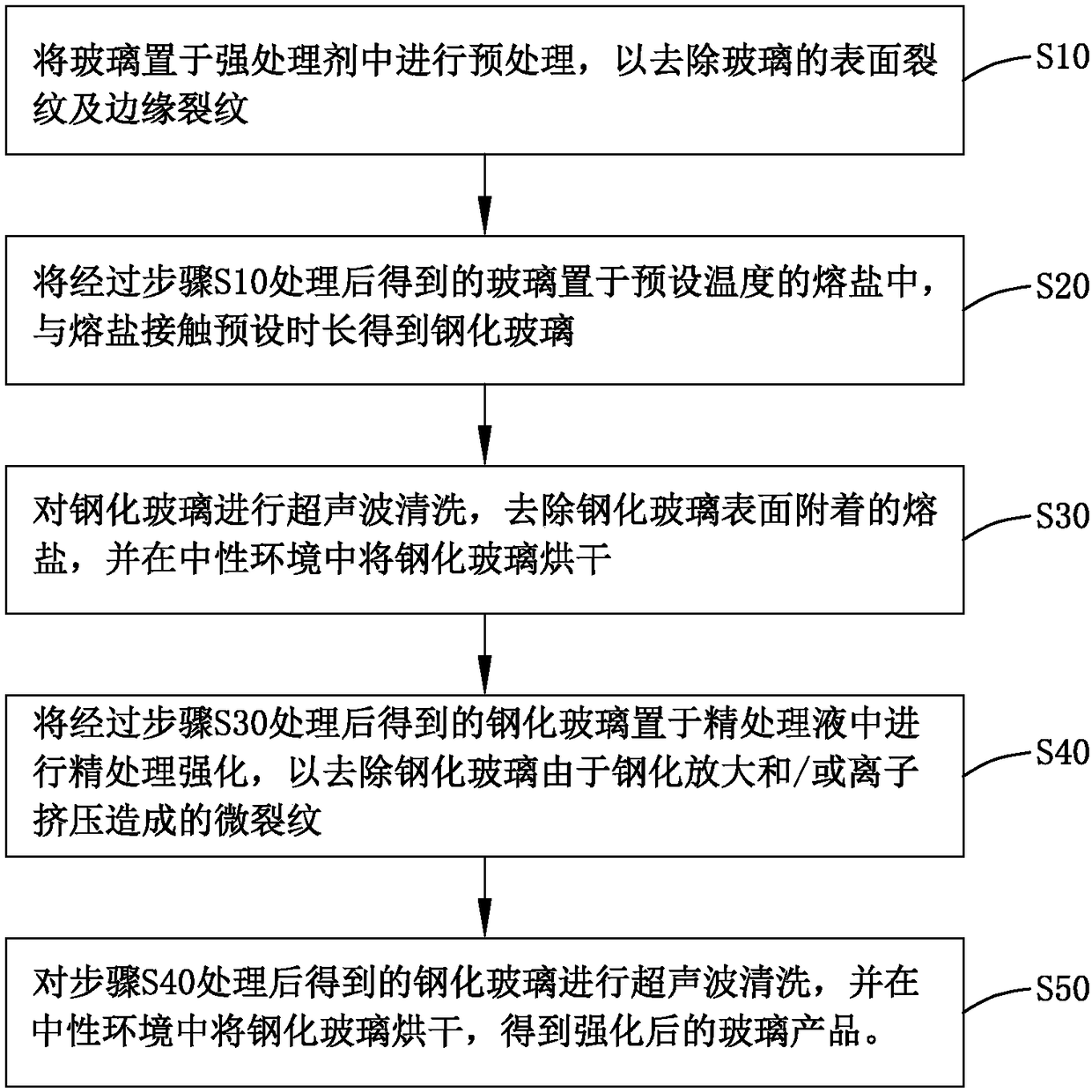

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for strengthening glass, the method for strengthening glass includes the following steps:

[0046](1) Soak the glass in a strong treatment agent at 20°C for 1 minute, and constantly rotate the glass. The components of the strong treatment agent are: hydrofluoric acid: 1%; sulfuric acid: 1%; lemon Acid: 1%; the balance is water. The mass concentration of the hydrofluoric acid is 20%. After the reaction was completed, the glass was ultrasonically cleaned and dried in a nitrogen environment.

[0047] (2) Preheat the dried glass to slowly increase the temperature to 380° C., place the preheated glass in molten potassium nitrate salt at 380° C., and strengthen it for 200 minutes to obtain tempered glass.

[0048] (3) Take out the tempered glass, slowly anneal to room temperature, ultrasonically clean the tempered glass and dry it in a nitrogen environment.

[0049] (4) Place the dried tempered glass in a finishing solution at 30°C for 5 m...

Embodiment 2

[0051] This embodiment provides a method for strengthening glass, the method for strengthening glass includes the following steps:

[0052] (1) Soak the glass in a strong treatment agent at 25°C for 5 minutes, and constantly rotate the glass. The components of the strong treatment agent are: hydrofluoric acid: 5%; nitric acid: 25%; glucose Acid: 10%; balance is water. The mass concentration of the hydrofluoric acid is 30%. After the reaction was completed, the glass was ultrasonically cleaned and dried in a nitrogen environment.

[0053] (2) Preheating the dried glass to slowly increase the temperature to 400° C., place the preheated glass in molten potassium nitrate salt at 400° C., and strengthen it for 300 minutes to obtain tempered glass.

[0054] (3) Take out the tempered glass, slowly anneal to room temperature, ultrasonically clean the tempered glass and dry it in a nitrogen environment.

[0055] (4) Place the dried tempered glass in a finishing solution at 40°C for ...

Embodiment 3

[0057] This embodiment provides a method for strengthening glass, the method for strengthening glass includes the following steps:

[0058] (1) Soak the glass in a strong treatment agent at 30°C for 10 minutes, and constantly rotate the glass. The components of the strong treatment agent are: hydrofluoric acid: 10%; phosphoric acid: 50%; Diaminetetraacetic acid: 20%; the balance is water. The mass concentration of the hydrofluoric acid is 40%. After the reaction was completed, the glass was ultrasonically cleaned and dried in a nitrogen environment.

[0059] (2) Preheating the dried glass to slowly increase the temperature to 450° C., place the preheated glass in molten sodium nitrate salt at 450° C., and strengthen it for 400 minutes to obtain tempered glass.

[0060] (3) Take out the tempered glass, slowly anneal to room temperature, ultrasonically clean the tempered glass and dry it in a nitrogen environment.

[0061] (4) Place the dried tempered glass in a finishing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com