A kind of inorganic sludge curing agent, road construction material and preparation method thereof

A technology of curing agent and sludge, applied in the field of road construction materials and their preparation, road construction materials, and inorganic sludge curing agent, can solve the problems of unsatisfactory use effect, dependence on curing effect, poor precipitation effect, etc., and achieve good physical and chemical Stability, beneficial to the protection of the environment, the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

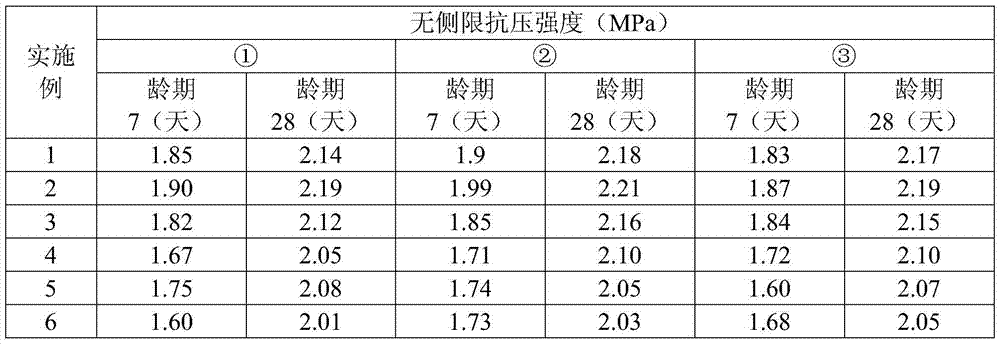

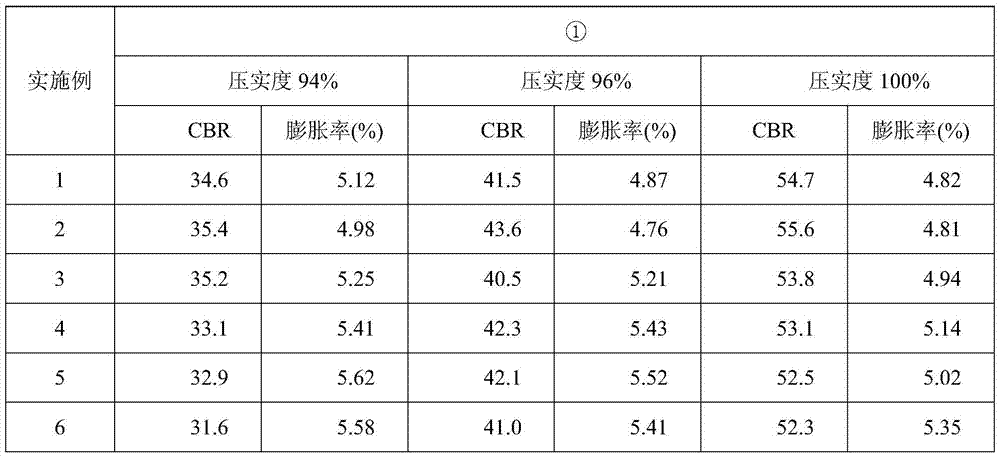

Embodiment 1

[0035] This embodiment provides a road construction material, which is made by mixing 21kg of inorganic silt curing agent, 6kg of cement, 22kg of construction waste, and 51kg of silt.

[0036] The inorganic sludge solidifying agent of the present embodiment consists of 42 parts of natural pumice powder and 58 parts of hectorite powder in parts by weight. Wherein, the preparation method of the inorganic sludge solidifying agent of the present embodiment is:

[0037] Step 1: crushing pumice minerals and laponite minerals and passing them through a 0.15mm square hole sieve, retaining the under-sieve, and preparing pumice powder and laponite powder for later use;

[0038] Step 2: Calcining the natural pumice powder and hectorite powder prepared in Step 1 in a high-temperature furnace at a calcination temperature of 550° C. for 3 hours;

[0039] Step 3: Place the pumice powder and laponite powder obtained in step 2 in a sulfuric acid solution with an acid solution concentration of...

Embodiment 2

[0042] This embodiment provides a road construction material, which is made by mixing 10kg of inorganic silt curing agent, 10kg of cement, 25kg of construction waste and 55kg of silt.

[0043] In parts by weight, the inorganic sludge solidifying agent in this embodiment is composed of 49 parts of natural pumice powder and 51 parts of hectorite powder. Wherein, the preparation method of the inorganic sludge solidifying agent of the present embodiment is:

[0044] Step 1: crushing pumice minerals and laponite minerals and passing them through a 0.15mm square hole sieve, retaining the under-sieve, and preparing pumice powder and laponite powder for later use;

[0045] Step 2: Calcining the natural pumice powder and hectorite powder prepared in Step 1 in a high-temperature furnace at a calcination temperature of 550° C. for 3 hours;

[0046] Step 3: Place the pumice powder and laponite powder obtained in step 2 in a sulfuric acid solution with an acid solution concentration of 2.4 ...

Embodiment 3

[0049] This embodiment provides a road construction material, which is made by mixing 16kg of inorganic silt curing agent, 7kg of cement, 24kg of construction waste, and 53kg of silt.

[0050] In parts by weight, the inorganic sludge solidifying agent in this embodiment is composed of 46 parts of natural pumice powder and 54 parts of hectorite powder. Wherein, the preparation method of the inorganic sludge solidifying agent of the present embodiment is:

[0051] Step 1: crushing pumice minerals and laponite minerals and passing them through a 0.15mm square hole sieve, retaining the under-sieve, and preparing pumice powder and laponite powder for later use;

[0052] Step 2: Calcining the natural pumice powder and hectorite powder prepared in Step 1 in a high-temperature furnace at a calcination temperature of 550° C. for 3 hours;

[0053] Step 3: Place the pumice powder and laponite powder obtained in step 2 in a sulfuric acid solution with an acid solution concentration of 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com