Carboxymethyl cellulose/aramid nano fiber composite membrane as well as preparation method and application thereof

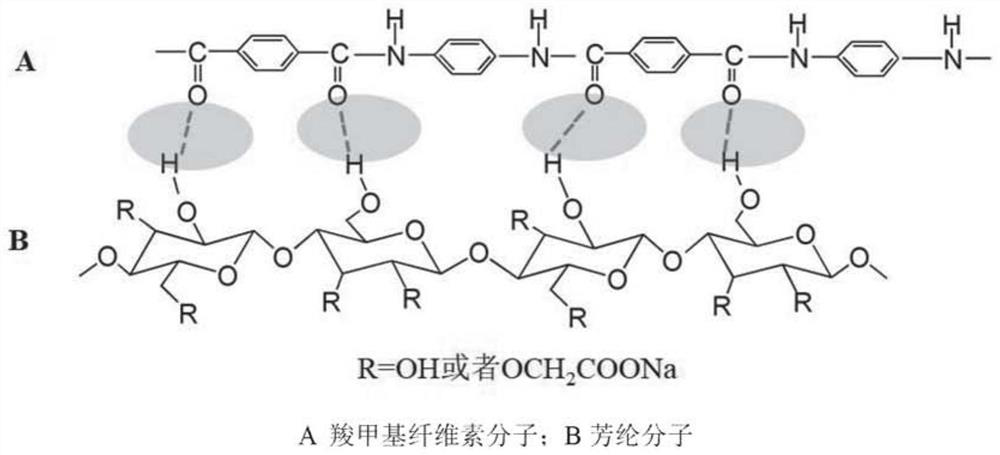

A carboxymethyl cellulose and nanofiber technology, which is applied in the field of carboxymethyl cellulose/aramid nanofiber composite membrane and its preparation, can solve the problems such as unseen, low activity, weak interface bonding force, etc. Excellent shielding performance, simple preparation process, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

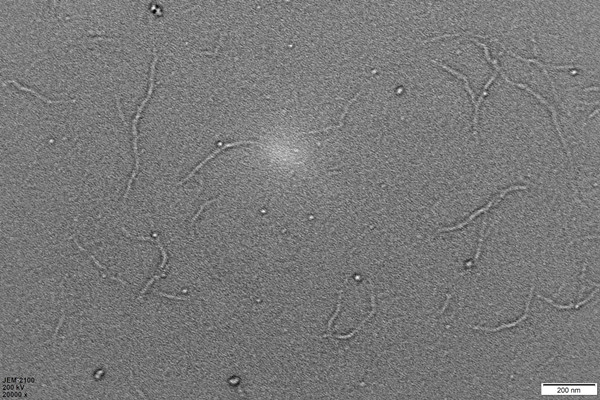

[0034] 0.5 g of aramid fibers and 0.75 g of potassium hydroxide were added to 250 g of dimethyl sulfoxide, and magnetically stirred to form an aramid nanofiber / potassium hydroxide / dimethyl sulfoxide solution. Add 200ml of deionized water to 100ml of aromatic nanofiber / potassium hydroxide / dimethyl sulfoxide solution, stir evenly with a magnetic stirrer, then filter under vacuum pressure, and repeatedly wash with deionized water and alcohol to remove residual potassium hydroxide and Dimethyl sulfoxide. Then disperse the washed aramid nanofibers into deionized water to obtain an aqueous dispersion of aramid nanofibers, and the mass ratio of the washed aramid nanofibers to deionized water is 1:500.

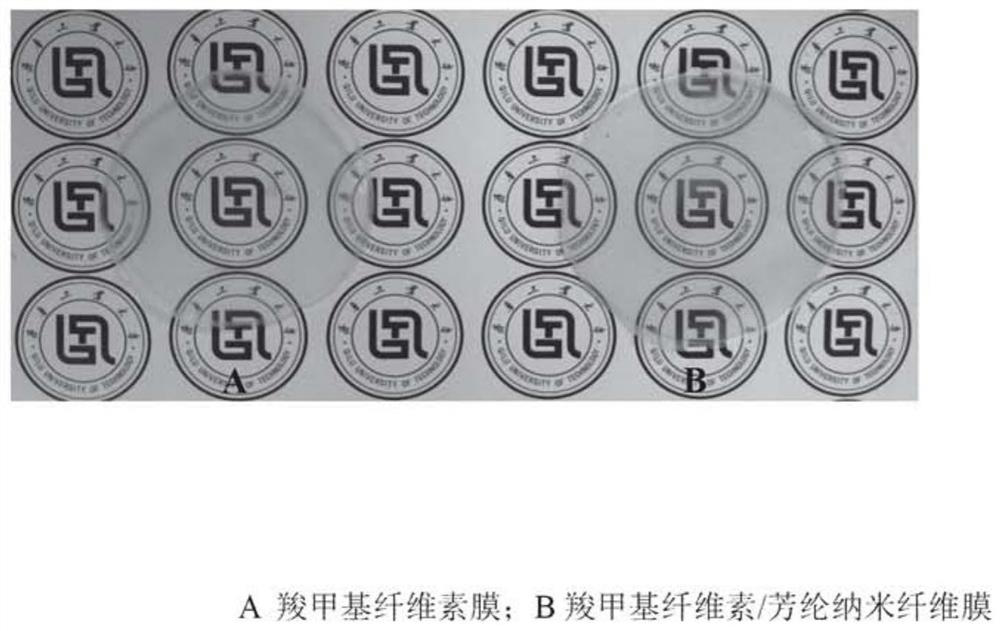

[0035] Weigh 2 g of carboxymethylcellulose powder, add deionized water, and stir magnetically at a constant temperature in a water bath at 50° C. for 4 hours to obtain a uniform and transparent solution. The carboxymethyl cellulose solution and aramid nanofiber solution configured ab...

Embodiment 2

[0037] 0.5 g of aramid fibers and 0.75 g of potassium hydroxide were added to 250 g of dimethyl sulfoxide, and magnetically stirred to form an aramid nanofiber / potassium hydroxide / dimethyl sulfoxide solution. Add 200ml of deionized water to 100ml of aromatic nanofiber / potassium hydroxide / dimethyl sulfoxide solution, stir evenly with a magnetic stirrer, then filter under vacuum pressure, and repeatedly wash with deionized water and alcohol to remove residual potassium hydroxide and Dimethyl sulfoxide. Then disperse the washed aramid nanofibers into deionized water to obtain an aqueous dispersion of aramid nanofibers, and the mass ratio of the washed aramid nanofibers to deionized water is 1:250.

[0038] Weigh 2 g of carboxymethylcellulose powder, add deionized water, and stir magnetically at a constant temperature in a water bath at 50° C. for 4 hours to obtain a uniform and transparent solution. The carboxymethyl cellulose solution and aramid nanofiber solution configured ab...

Embodiment 3

[0040]0.5 g of aramid fibers and 0.75 g of potassium hydroxide were added to 250 g of dimethyl sulfoxide, and magnetically stirred to form an aramid nanofiber / potassium hydroxide / dimethyl sulfoxide solution. Add 200ml of deionized water to 100ml of aromatic nanofiber / potassium hydroxide / dimethyl sulfoxide solution, stir evenly with a magnetic stirrer, then filter under vacuum pressure, and repeatedly wash with deionized water and alcohol to remove residual potassium hydroxide and Dimethyl sulfoxide. Then disperse the washed aramid nanofibers into deionized water to obtain an aqueous dispersion of aramid nanofibers, and the mass ratio of the washed aramid nanofibers to deionized water is 1:750.

[0041] Weigh 2 g of carboxymethylcellulose powder, add deionized water, and stir magnetically at a constant temperature in a water bath at 50° C. for 4 hours to obtain a uniform and transparent solution. The carboxymethyl cellulose solution and aramid nanofiber solution configured abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com