Formula for enhancing toughness and strength of calcium carbonate highly-filled PP polyethylene material

A calcium carbonate and polyethylene technology, applied in the field of toughness and strength formulations, can solve problems such as not being able to be greatly improved, and achieve the effects of improving Young's modulus, high toughness and notched impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

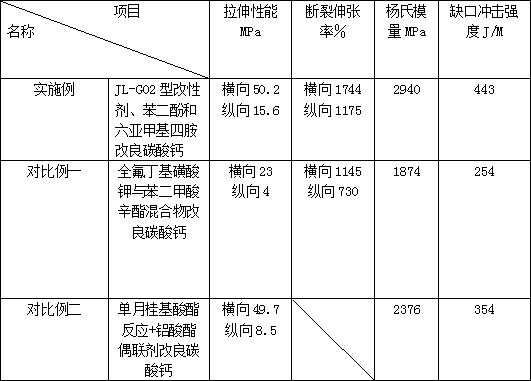

Examples

Embodiment Construction

[0022] In an embodiment of the present invention, a formula for enhancing toughness and strength of a calcium carbonate highly filled PP polyethylene material includes the following components: ethylene, polyethylene catalyst, propylene, polypropylene catalyst and calcium carbonate, each component is by weight The composition is as follows: 50-55 parts of ethylene, 5-10 parts of polyethylene catalyst, 10-15 parts of propylene, 1-2 parts of polypropylene catalyst and 1-2 parts of calcium carbonate.

[0023] Preferably, the polyethylene catalyst includes a U-J catalyst and a co-catalyst, the U-J catalyst consists of tetrahydrofuran, magnesium chloride, titanium trichloride, tri-n-hexyl aluminum mineral oil and diethyl aluminum chloride, and the co-catalyst is triethyl aluminum, wherein, The content ratio of tetrahydrofuran, magnesium chloride, titanium trichloride, tri-n-hexyl aluminum mineral oil, diethyl aluminum chloride and triethyl aluminum is 3:2:2:2:3:1.

[0024] Preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com