Chemical tempering treatment method of glass

A chemical tempering and glass technology, applied in the field of glass preparation, can solve problems such as blocking the exchange layer and affecting the exchange depth, and achieve the effects of improving warpage, enhancing high-strength glass, and reducing differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

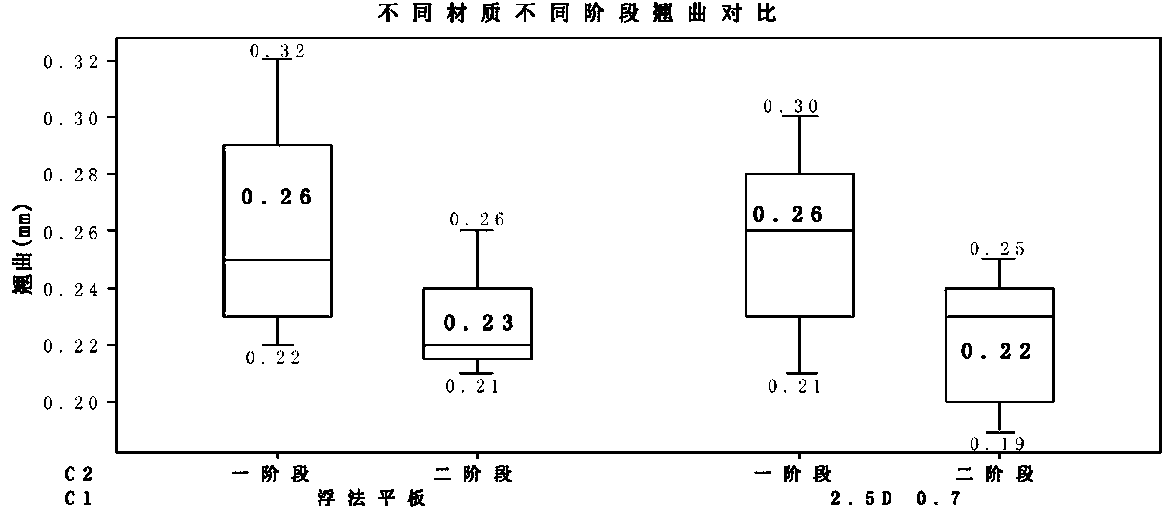

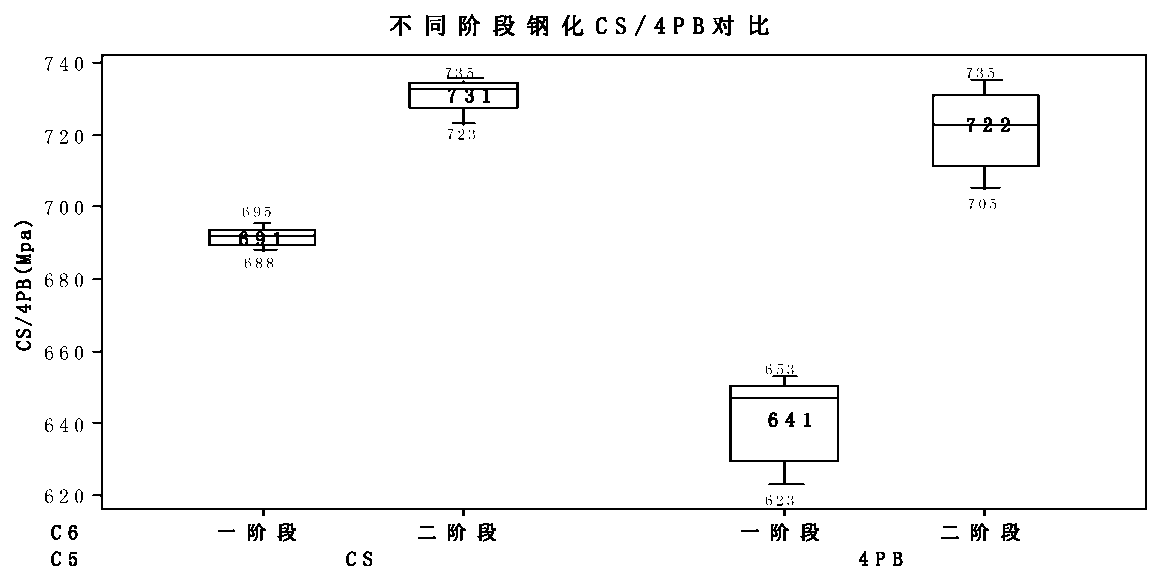

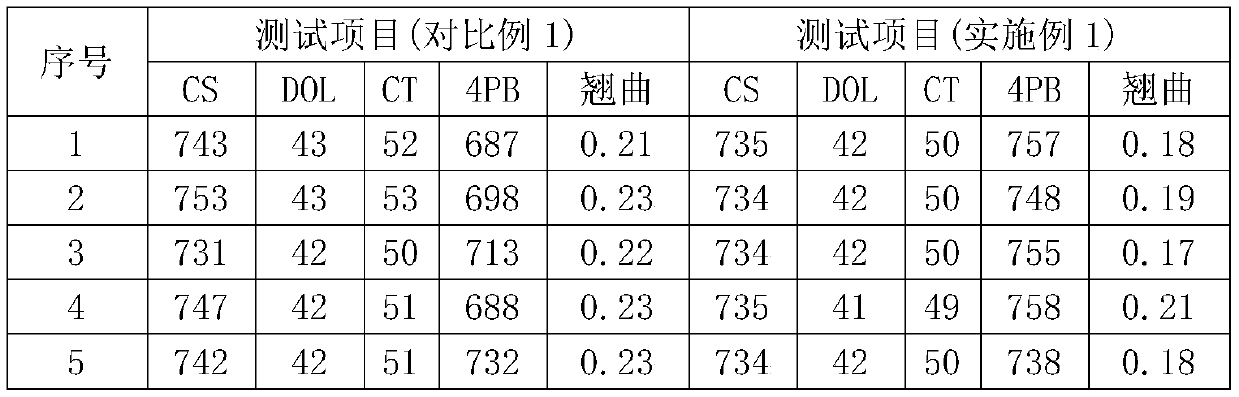

[0025] Embodiment 1: A method for chemically tempering glass, the glass is 0.7mm 2.5D shaped glass. The specific ingredients are in molar ratio: 68 parts of SiO 2 , 13 Al 2 o 3 , 12 Na 2 O, 3 copies of K 2 O, 3 parts MgO and 1 part ZrO 2 .

[0026] Specific process:

[0027] 1) The selected glass is soaked in the first salt bath (sodium nitrate 3wt%). The temperature of the salt bath is 440°C, and the soaking time is 3h. After soaking, it is rapidly annealed at room temperature, and the annealing time is ≤30min: salt bath soaking Complete cooling annealing at room temperature immediately after completion; fan can be used for rapid cooling

[0028] 2) The annealed glass obtained in step 1) is placed in the second salt bath (sodium nitrate 3wt%) for soaking. The temperature of the salt bath is 390° C., and the soaking time is 50 minutes. 20min: Complete cooling annealing at room temperature immediately after salt bath immersion;

[0029] Through the above treatment, the...

Embodiment 2

[0039] Embodiment 2: the method for glass chemical toughening treatment, wherein the specific composition of glass is: 68 parts of SiO by molar ratio 2 , 5 Al 2 o 3 , 10 parts of Na 2 O, 5 copies of K 2 O, 9 parts of MgO, 1 part of CaO.

[0040] Thickness: 0.55mm flat glass.

[0041] The specific steps are:

[0042] 1) The selected glass is soaked in the first salt bath (sodium nitrate 6wt%), the temperature of the salt bath is 440°C, and the soaking time is 5h. After soaking, it is rapidly annealed at room temperature, and the annealing time is ≤30min: salt bath soaking Complete cooling annealing at room temperature immediately after completion;

[0043] 2) The annealed glass obtained in step 1) is placed in the second salt bath (sodium nitrate 10wt%) for soaking. The temperature of the salt bath is 380° C., and the soaking time is 60 minutes. 20min: Complete cooling annealing at room temperature immediately after salt bath immersion;

[0044] Through the above treatm...

Embodiment 3

[0056] A method for chemical tempering treatment of glass, wherein the specific composition of the glass is: 68 parts of SiO in molar ratio 2 , 15 Al 2 o 3 , 12 Na 2 O, 3 copies of K 2 O, 2 parts of MgO.

[0057] Thickness: 0.7mm 2.5D shape glass.

[0058] The specific steps are:

[0059] 1) The selected glass is immersed in the first salt bath (sodium nitrate 5wt%). The temperature of the salt bath is 440°C, and the soaking time is 5h. Complete cooling annealing at room temperature immediately after completion;

[0060] 2) The annealed glass obtained in step 1) is placed in the second salt bath (sodium nitrate 5wt%) for soaking. The temperature of the salt bath is 400° C., and the soaking time is 30 minutes. 20min: Complete cooling annealing at room temperature immediately after salt bath immersion;

[0061] 3) The annealed glass obtained in step 2) is placed in the third salt bath (sodium nitrate 5wt%) for soaking. The temperature of the salt bath is 390° C., and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com