Fabrication method of beer bottle

A technology for beer bottles and raw materials, applied in the field of glass products, can solve problems such as environmental pollution and kiln erosion, and achieve the effects of reducing costs, reducing corrosion and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

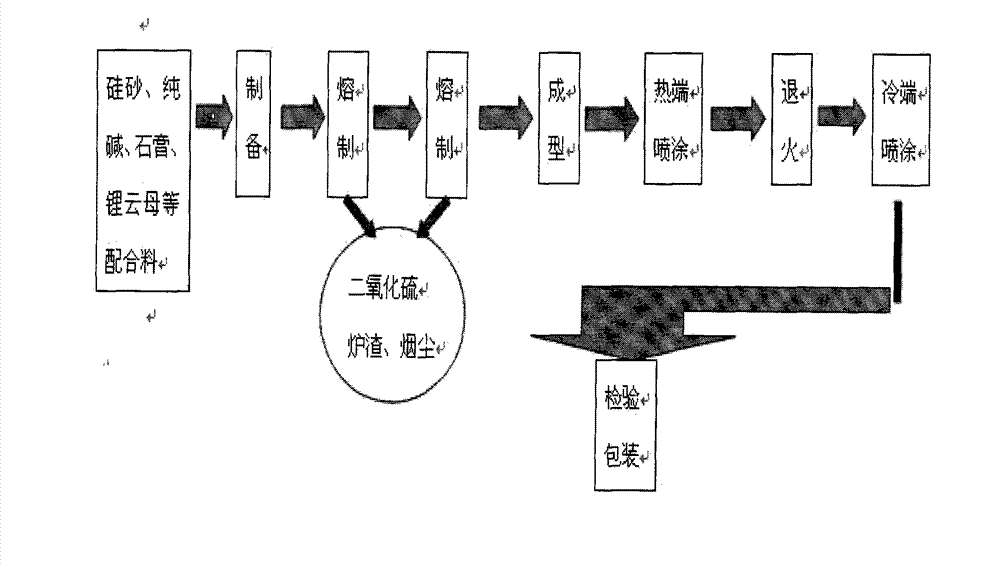

Method used

Image

Examples

Embodiment 1

[0034] The desulfurization gypsum used in this embodiment was purchased from Qingdao thermal power plant, CaSO 4 .2H 2 O≥90%.

[0035] Prepare the proportioning of the raw material of glass bottle as follows:

[0036] Quartz sand 1300kg, limestone 400kg, soda ash 300kg, lepidolite 30kg, fluorite 20kg, desulfurization gypsum 30kg, chrome ore powder 10kg, broken glass 3000kg.

[0037] Process conditions:

[0038] 1) Melting temperature: 1530°C±2°C, of which silicate formation temperature: 800°C-850°C; glass formation temperature: 1200°C-1250°C; glass clarification temperature: 1450°C-1480°C;

[0039] 2) Forming by determinant 8 sets of double drop machine, drop material temperature: 1080-1130°C;

[0040] 3) Use hot end spraying, the bottle temperature is 500°C;

[0041] 4) Annealing in an electric heating annealing furnace, the annealing temperature is 540°C-550°C.

[0042] 5) Use cold end spraying, the temperature is 80°C-120°C.

[0043] 6) Cold end inspection Use an e...

Embodiment 2

[0048] The desulfurization gypsum used in this embodiment is purchased from Qingdao thermal power plant, and the composition of gypsum is: CaSO 4 .2H 2 O≥90%.

[0049] The raw materials used are as follows:

[0050] Quartz sand 1350kg; limestone 500kg; soda ash 350kg; fluorite 20kg; desulfurization gypsum 50kg; chrome ore powder 20kg; cullet 4500kg.

[0051] Process conditions:

[0052] 1) Melting temperature: 1530°C±2°C, of which silicate formation temperature: 800°C-850°C; glass formation temperature: 1200°C-1240°C; glass clarification temperature: 1430°C-1460°C;

[0053] 2) Forming by determinant 8-group single-drop machine, drop material temperature: 1070-1120°C;

[0054] 3) Use hot end spraying, the bottle temperature is 550°C;

[0055] 4) Annealing in an electric heating annealing furnace, the annealing temperature is 540°C-550°C.

[0056] 5) Use cold end spraying, the temperature is 80°C-120°C.

[0057] 6) The cold end inspection uses an electronic automatic bott...

Embodiment 3

[0060] Prepare beer bottles according to the proportioning and steps of the examples, except that 15kg of talcum powder is added to the raw materials. As a result, the prepared beer bottles have better product internal pressure resistance than the beer bottles prepared in Example 2. Moreover, it also has better gloss than the beer bottle prepared in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com