Method for reducing machining stress concentration of glass hole

A technology for processing stress and glass holes, which is applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as stress concentration, achieve the effects of eliminating stress concentration, avoiding large chipping, and facilitating repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

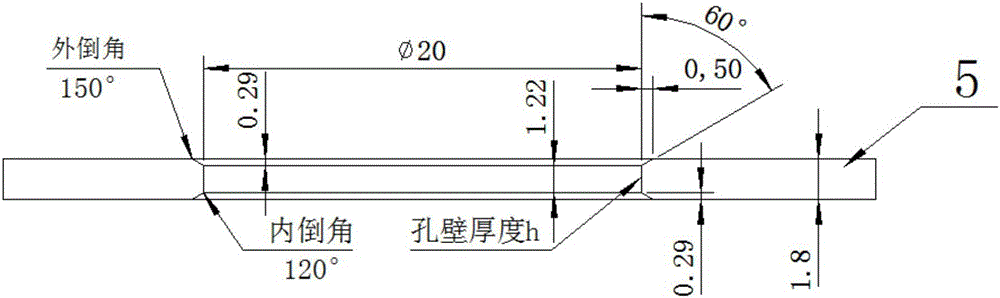

[0064] Set the glass thickness H, the hole diameter is Φ, the ring width b of the chamfer on the glass end face, and the glass thickness h of the hole wall after hole processing meets the strength requirements of the glass;

[0065] A method for reducing stress concentration in glass hole processing, comprising the following steps:

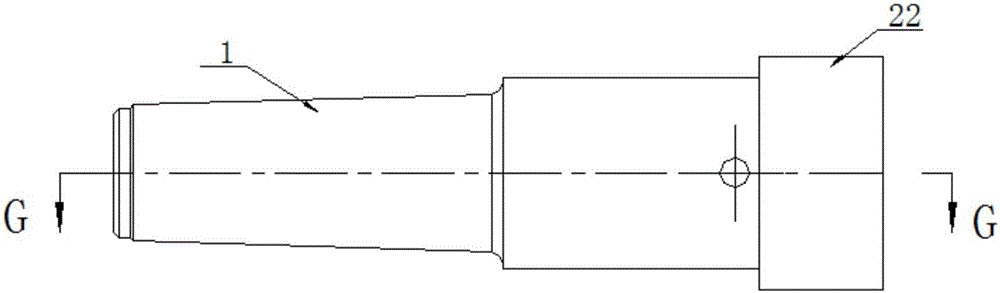

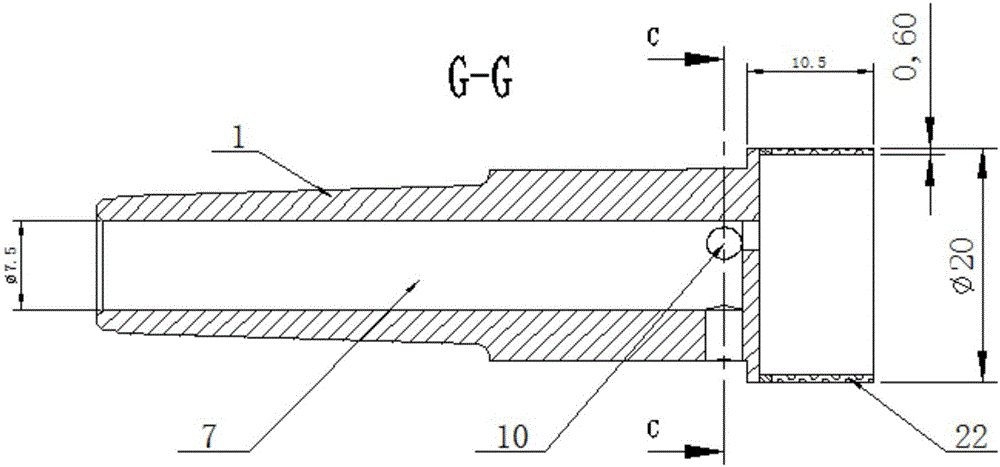

[0066] Step 1. Assemble the chamfering drill bit, put the end 4 with an outer diameter smaller than the set glass hole diameter close to the drill bit working ring 2, the chamfering ring 3 is on the rear side of the drill bit working ring 2 and the chamfering ring 3 is assembled on the drill bit base 1 ; The outer diameter φ1 of the terminal 4 is smaller than the aperture Φ of the set glass hole, where 0.5㎜≤Φ-φ1≤2㎜;

[0067] Step 2. Drilling process, the drill bit drills a transition groove on the lower end face of the glass 5, the depth of the drill groove at the outer diameter of the end face of the drill bit working ring 2 is less than the set ...

Embodiment 2

[0084] The glass used for solar cells has a thickness of H=1.8㎜ and a hole diameter of Φ=20㎜. Since the glass is under stress when the battery components are laminated, the stress concentration of the glass hole processing is one of the important factors for glass bursting, so it needs to be reduced. Stress concentration in hole machining.

[0085] Such as figure 1 As shown, in order to ensure the strength of the glass, the thickness of the hole wall is set not less than h=1.2㎜, in order to reduce the stress concentration, the chamfer width of the hole processing end face is b=0.5㎜, and the axial angle θ=60° (that is, the radial The included angle is 30°, D2 is the outer chamfer depth of the upper drilling process, and D1 is the inner chamfer depth of the second down drilling process. The calculation shows that: D2 = D1 = 0.29㎜), so that the 90° right angle of the hole becomes an obtuse angle (ie The angle of chamfering during secondary drilling is 90°+30°=120°).

[0086] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com