Multifunctional SLM device

A multifunctional filter device technology, applied in the field of laser 3D printing, can solve the problems that the gas containing particles and impurities cannot be reused, the preheating temperature is difficult to exceed 200°C, and it is not conducive to the maintenance of the molding room, so as to save time, cost and Economical cost, avoiding the danger of dust explosion, beneficial to maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

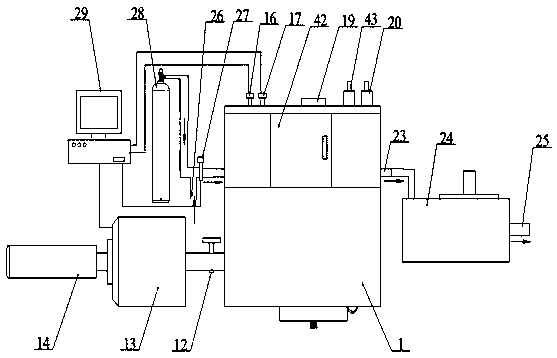

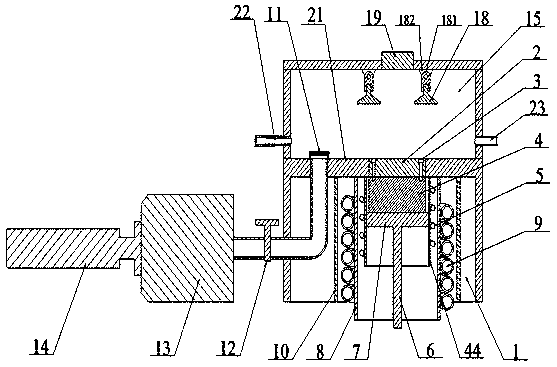

[0050] A multifunctional SLM device, such as figure 1 , 2 , 3, including a preheating module, a vacuum module, a gas circulation filter module, and a powder spreading mechanism, the preheating module is connected to the vacuum module, and the preheating module is connected to the gas circulation filter module;

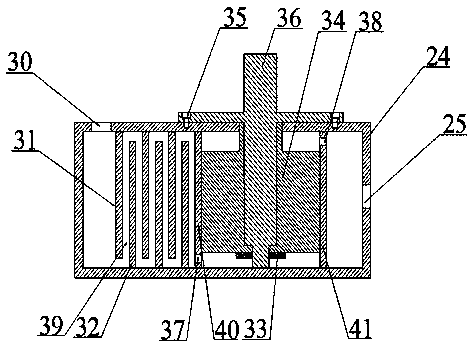

[0051] The preheating module includes a working box 1, a base plate 2, a bottom plate 4, an induction heating coil 5, a screw 6, a piston 7, a forming cylinder 8, a cold water pipe 9, a sleeve 10, a forming chamber 15, an infrared heating lamp 18, and a rotating head 181 , support 182, optical path channel 19, workbench 21, hatch 42, temperature sensor 43, heat preservation cover 44; vacuum module includes dustproof screen 11, solenoid valve I12, vacuum pump 13, muffler 14, oxygen content detector 16. Pressure sensor 17, safety valve 20; gas circulation filter module includes air inlet 22, exhaust port 23, filter device housing 24, air outlet 25, solenoid valve II 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com