Driving device

A technology of driving device and transmission device, applied in the direction of transmission device, cam follower, textile, etc., can solve the problems of position uncertainty, occupying a lot of space, unfavorable accumulation and removal of harmful substances, etc., to save costs and reduce inertia and the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

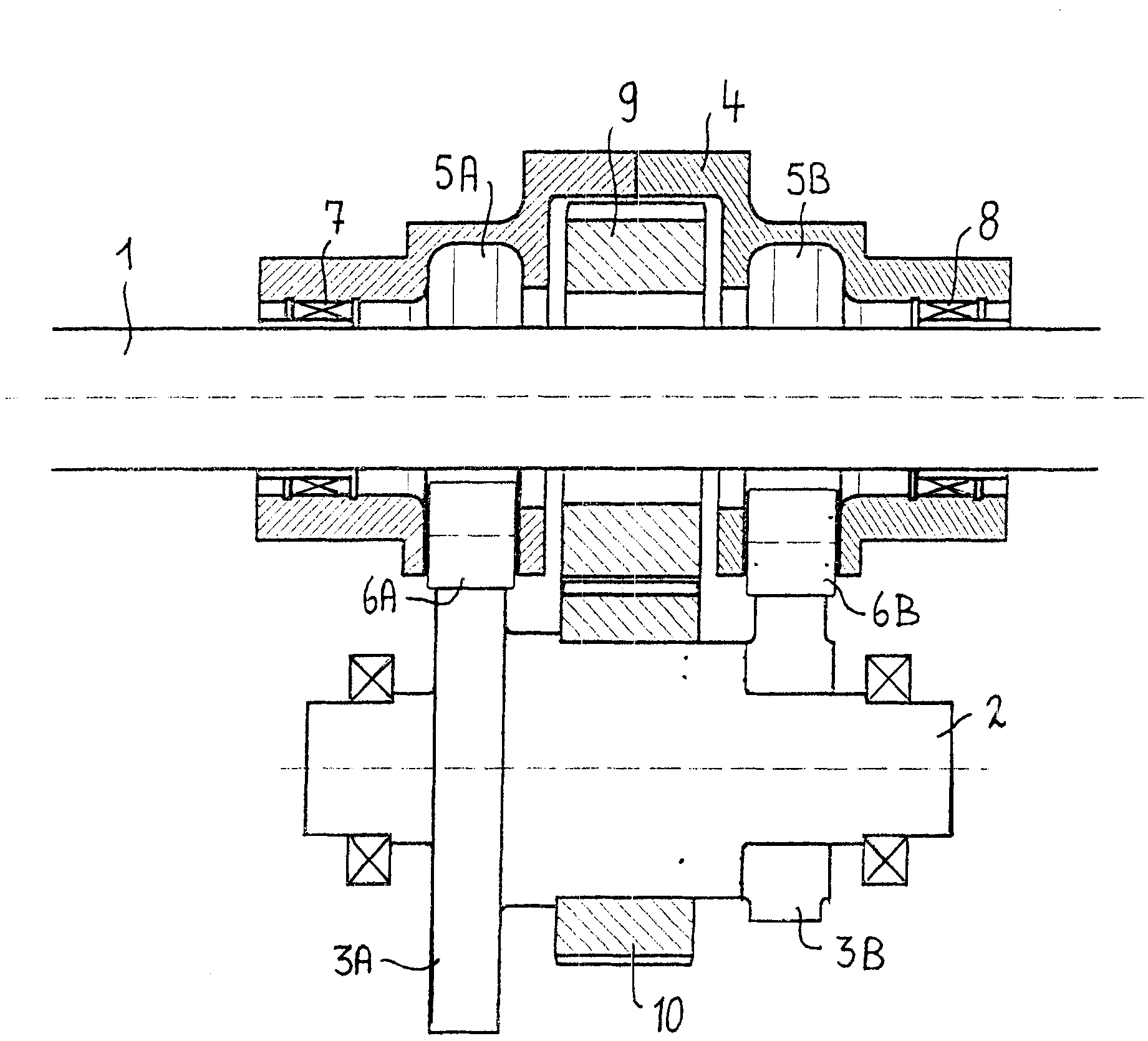

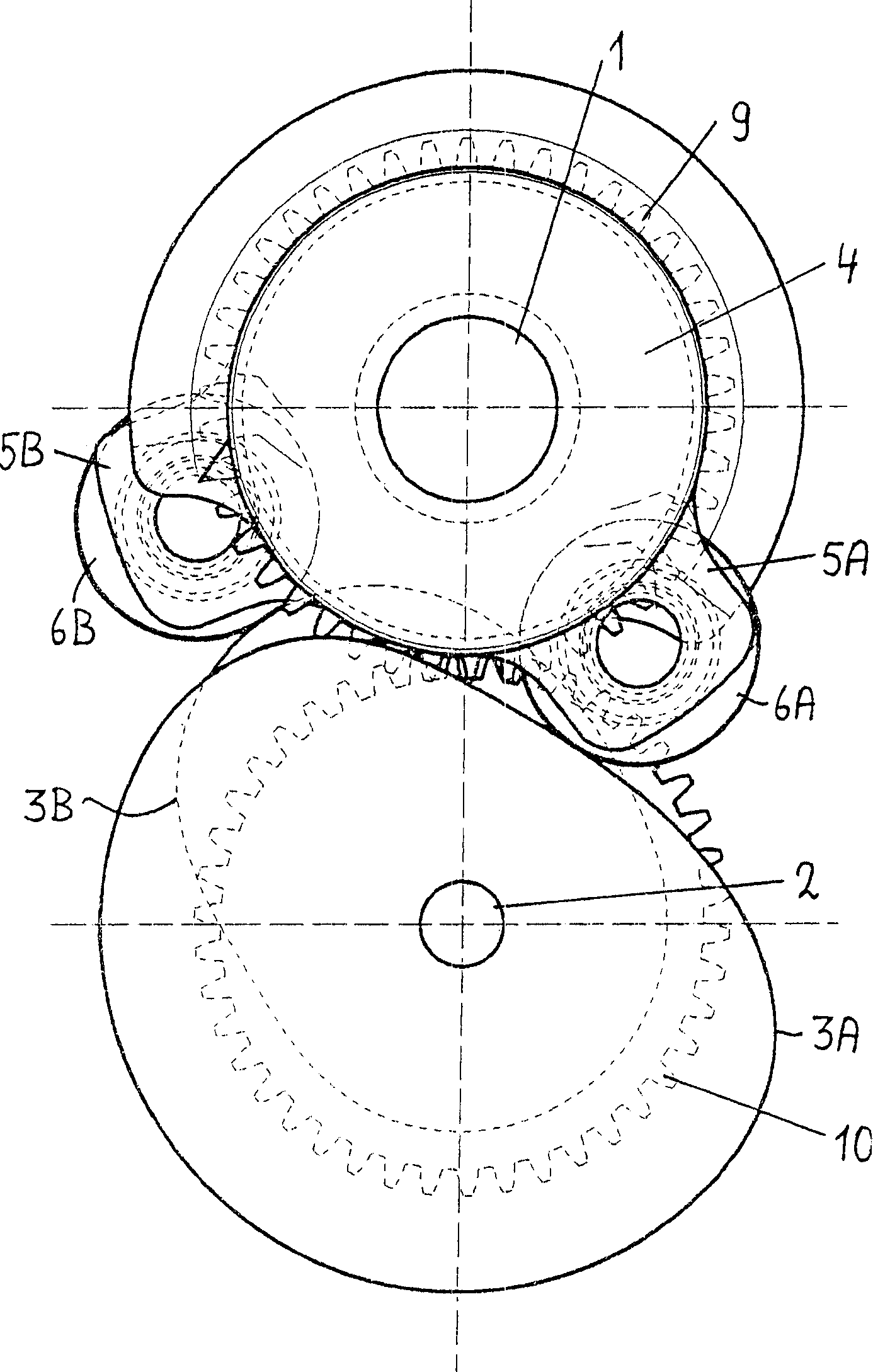

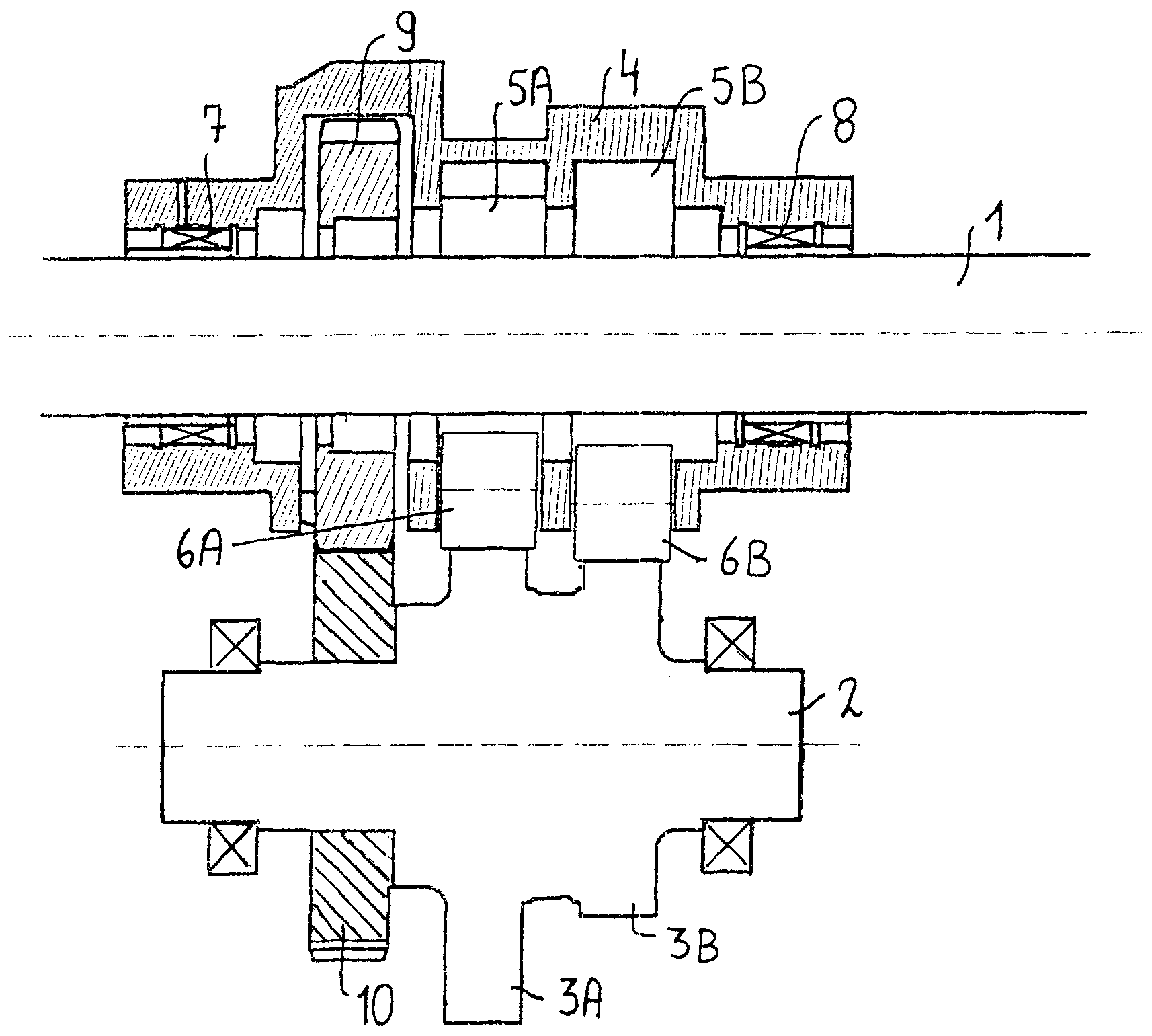

[0035] figure 1 with figure 2 A sectional view and a side view of a first embodiment of the invention are shown, the drive device comprising a drive shaft 1 and a cam shaft 2 . The drive shaft 1 and the cam shaft 2 are arranged with meshing gears 9, 10, respectively. Two conjugate cam disks 3A, 3B are respectively arranged on both sides of the gear wheel 10 on the camshaft 2 .

[0036] Arranged on the drive shaft 1 is a cam follower 4 , which is supported coaxially on the drive shaft 1 via two bearings 7 , 8 . Bearings 7 , 8 are located on the drive shaft 1 and are arranged on both sides of the gear 9 . The cam follower lever 4 has two first lever arms 5A, 5B, and transmission rollers 6A, 6B are respectively arranged at the ends of the first lever arms 5A, 5B. When the cam discs 3A, 3B rotate, the designed transmission The rollers 6A, 6B move along the periphery of a corresponding cam plate 3A, 3B, so that the cam follower 4 is repeatedly rotated. In addition, the cam f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com