Method for processing refractory wastewater by three-dimensional electrode coupled with oxidant

A three-dimensional electrode and oxidant technology, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problem that the degradation efficiency and degradation effect of pollutants need to be improved, increase the cost of wastewater treatment, and the types and quantities are limited To achieve the effect of improving the efficiency of wastewater treatment, reducing the difficulty of mud-water separation and reducing the difficulty of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

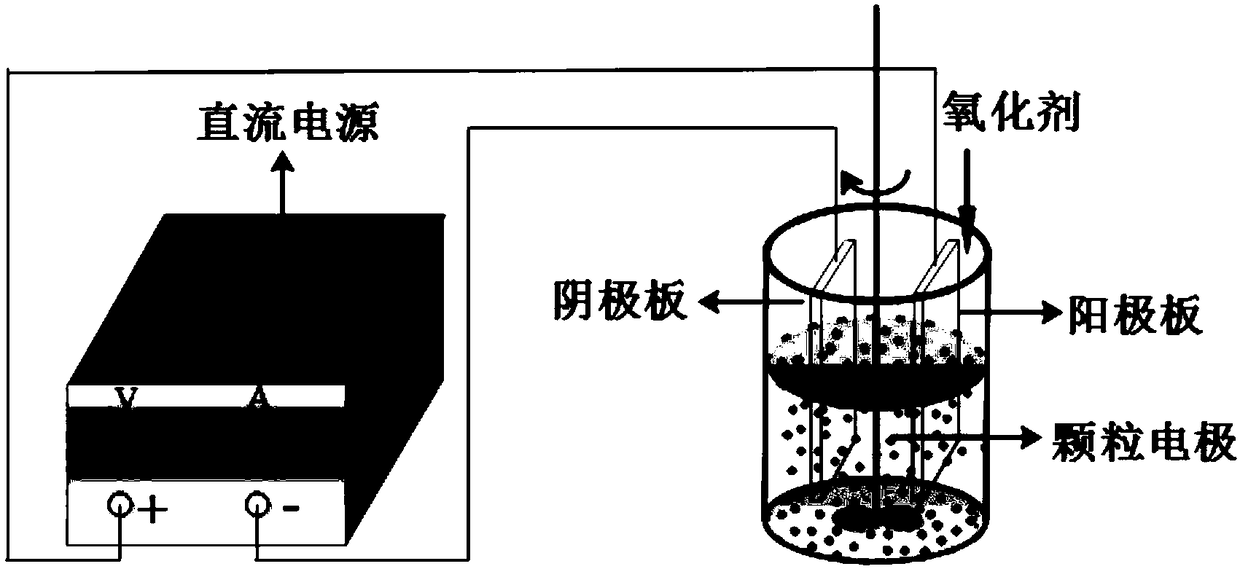

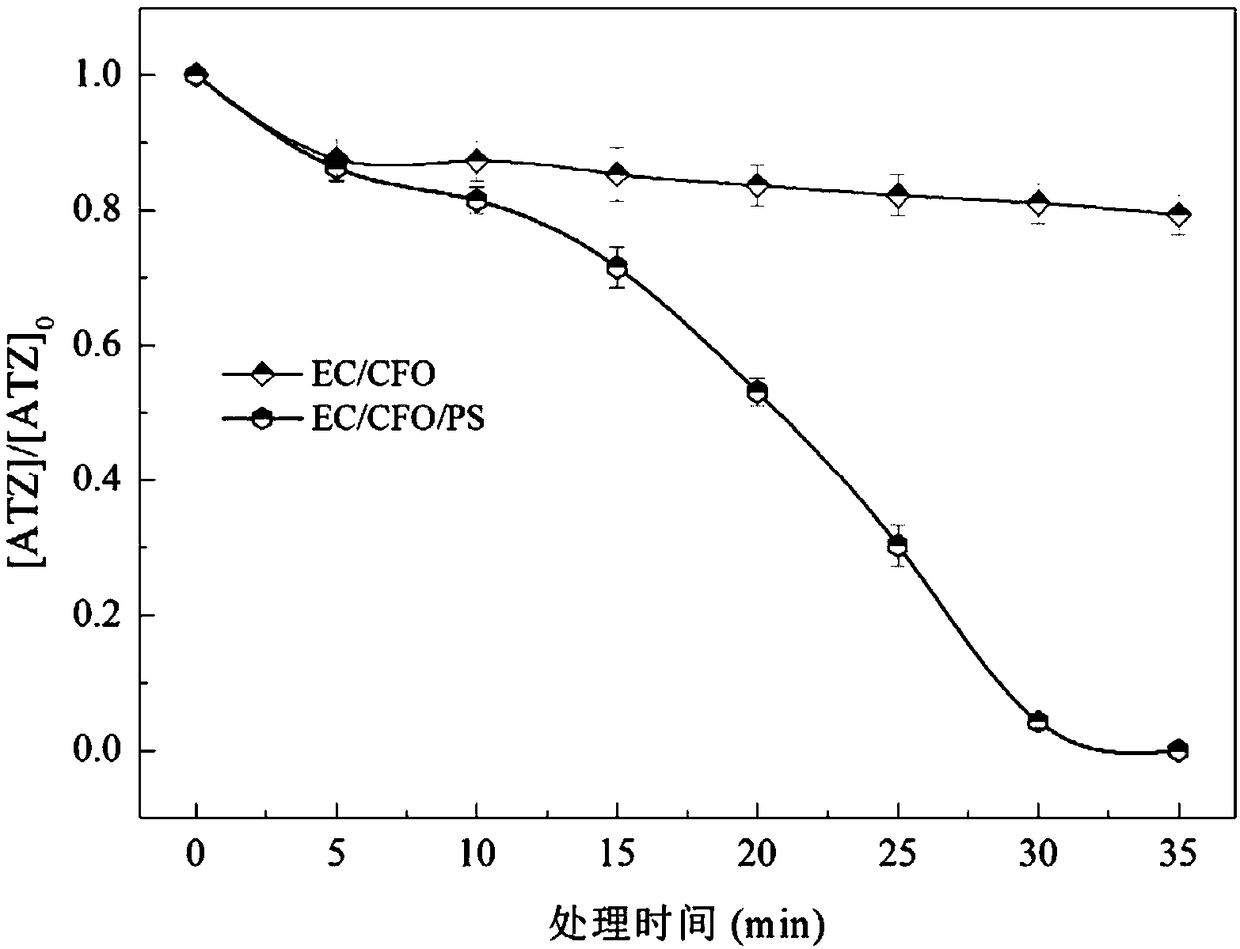

[0029] In this example, atrazine (ATZ, chemical name 2-chloro-4-diethylamino-6-isopropylamino-1, 3, 5) with a concentration of 10 mg / L and a pH adjusted to 6.3 -Triazine) solution is used as simulated wastewater to illustrate the method for treating refractory wastewater with three-dimensional electrode coupled with oxidant provided by the present invention. The steps are as follows:

[0030] (1) Put two electrode plates with a size of 5cm×11cm in the waste water treatment container. The two electrode plates are facing and parallel to each other and connected to a DC power supply. The anode plate is a composite metal oxide Ti / RuO. 2 -IrO 2 The cathode plate is a stainless steel plate, and the distance between the anode plate and the cathode plate is 57mm. Add 200 mL of simulated wastewater to a wastewater treatment container with anode and cathode plates.

[0031] (2) Add copper ferrite (CuFe 2 O 4 , CFO) particles, the amount of CFO particles added is 3g per liter of simulated was...

Embodiment 2

[0036] In this example, sulfamethoxazole (SMX, the chemical name is 4-amino-N-(5-methyl-3-isoxazolyl)benzenesulfonamide with a concentration of 10 mg / L and a pH adjusted to 7.0 ) The solution is used as simulated wastewater to illustrate the method for treating refractory wastewater with three-dimensional electrode coupled oxidant provided by the present invention, and the steps are as follows:

[0037] (1) Put two electrode plates with a size of 5cm×11cm in the waste water treatment container. The two electrode plates are facing and parallel to each other and connected to the DC power supply. Among them, the anode plate is a nickel plate and the cathode plate is a stainless steel plate. , The distance between the anode plate and the cathode plate is 65mm. Add 200 mL of simulated wastewater to the wastewater treatment container with anode and cathode plates, and then add electrolyte Na 2 SO 4 , Na 2 SO 4 The added amount is 10mmol per liter of wastewater.

[0038] (2) Add zinc fer...

Embodiment 3

[0040] In this embodiment, a 2,4-dinitrophenol (2,4-DNP) solution with a concentration of 50 mg / L and a pH adjusted to 7.0 is used as simulated wastewater to illustrate that the three-dimensional electrode coupled oxidant provided by the present invention is difficult to degrade. The waste water method, the steps are as follows:

[0041] (1) Put two electrode plates with a size of 5cm×11cm in the waste water treatment container. The two electrode plates are facing and parallel to each other and connected to the DC power supply. Among them, the anode plate is a titanium plate and the cathode plate is a graphite plate. , The distance between the anode plate and the cathode plate is 80mm. Add 200 mL of simulated wastewater to a wastewater treatment container with anode and cathode plates.

[0042] (2) Add manganese ferrite (MnFe 2 O 4 , MFO) particles, the amount of MFO particles added is 4g per liter of simulated wastewater, and then sodium peroxodisulfate (PS) is added in the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com